Transportation container

A technology for containers and cartons, which is applied in transportation and packaging, passenger car transportation, packaging, etc. It can solve the problems of poor water absorption and stretch resistance, short service life of wet curtain paper, and influence on indoor air quality, so as to improve water absorption performance , low cost, and the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The preparation method of the acetic acid-sodium acetate buffer solution is as follows: add 3.86g of glacial acetic acid and 2.93g of sodium acetate into 1L of distilled water, and mix well.

[0075] Melamine, CAS number: 108-78-1, product number M108433, was purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.

[0076] Ultrasonic treatment equipment is ST-1004 type ultrasonic generator, purchased from Shanghai Jieli Technology Co., Ltd.

[0077] The microwave equipment is a CY-PC180C-S microwave reactor, purchased from Hunan Changyi Microwave Technology Co., Ltd.

[0078] The vacuum freeze-drying equipment is LGJ-30D vacuum freeze-drying machine, which was purchased from Shanghai Bannuo Biotechnology Co., Ltd.

Embodiment 1

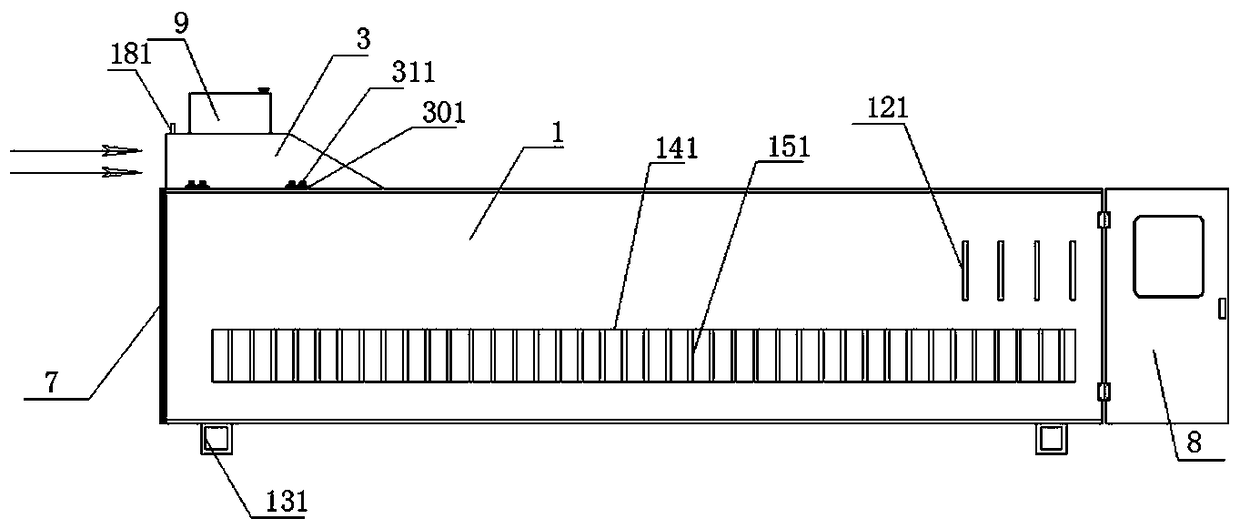

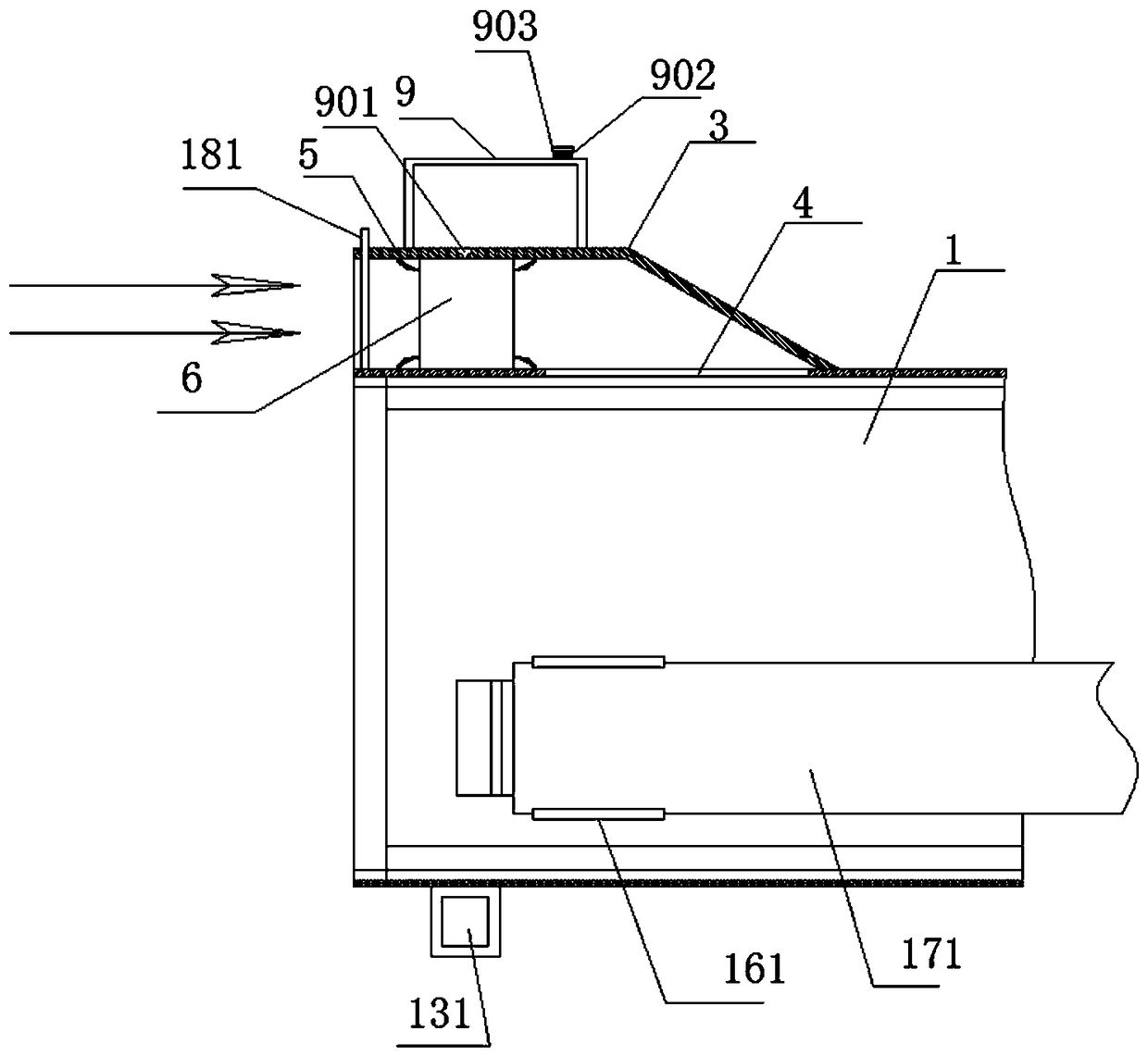

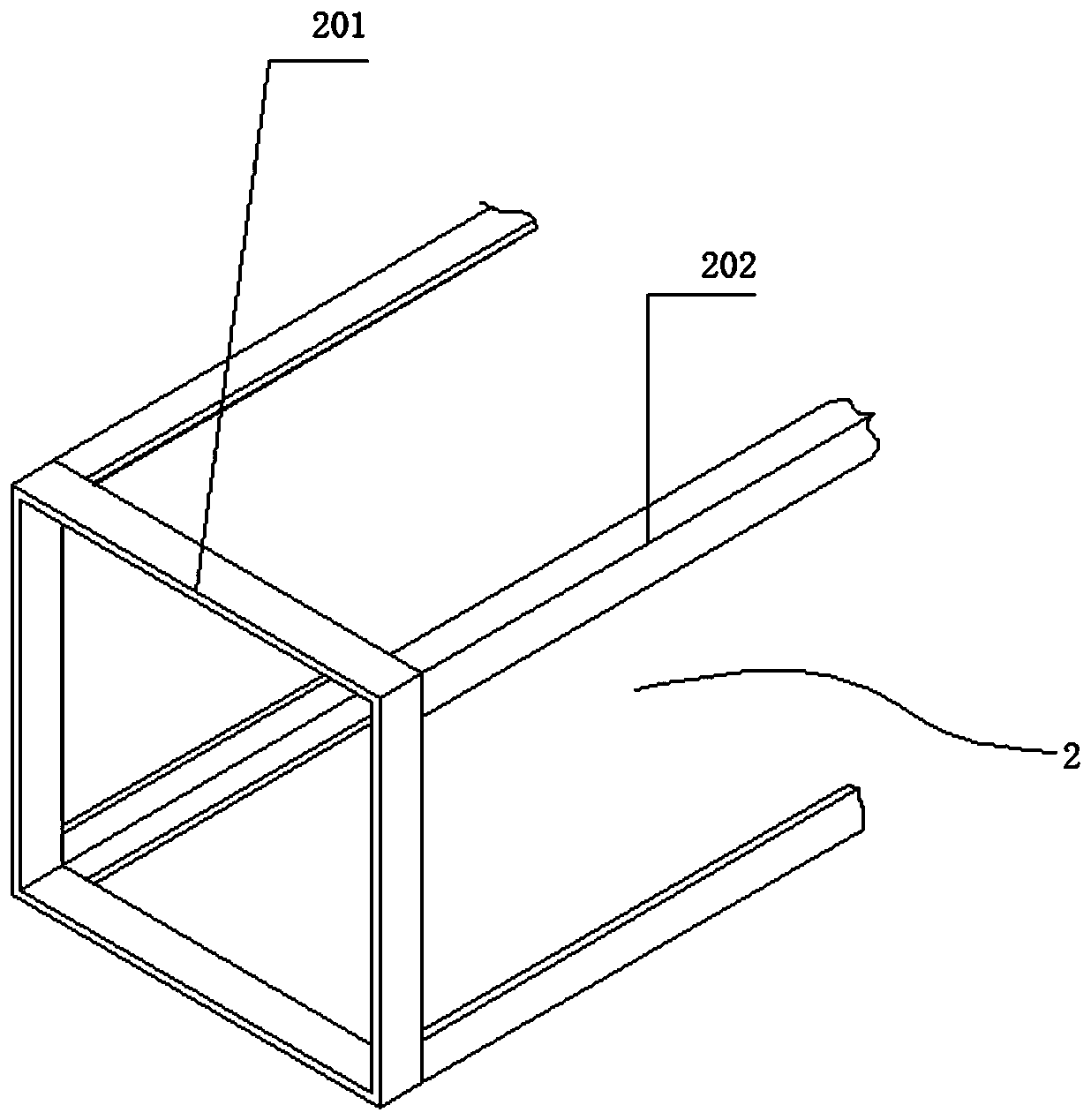

[0080] Such as Figure 1 to Figure 5The shown transport container includes an outer box body 1 with a stainless steel plate structure, and a skeleton 2 arranged inside the outer box body 1. The skeleton 2 includes two symmetrically arranged frames 201, and welded on the two sides. A side beam 202 at the position of the frame 201, the side beam 202 adopts a right-angle steel beam, the upper end of the outer box 1 is provided with an air inlet box 3, and the front and rear sides of the air inlet box 3 are both An ear portion 301 for connection is welded, and a screw 311 is fitted between the ear portion 301 and the outer box body 1, and an air inlet groove corresponding to the air inlet box 3 is arranged on the top of the outer box body 1 4. Four arc-shaped fixing plates 5 are symmetrically welded at the top of the outer box 1 and the inner top of the air inlet box 3, and a wet curtain is fixed between the four fixing plates 5 Carton 6, honeycomb-shaped ventilation holes 601 ar...

Embodiment 2

[0088] Such as Figure 1 to Figure 5 The shown transport container includes an outer box body 1 with a stainless steel plate structure, and a skeleton 2 arranged inside the outer box body 1. The skeleton 2 includes two symmetrically arranged frames 201, and welded on the two sides. A side beam 202 at the position of the frame 201, the side beam 202 adopts a right-angle steel beam, the upper end of the outer box 1 is provided with an air inlet box 3, and the front and rear sides of the air inlet box 3 are both An ear portion 301 for connection is welded, and a screw 311 is fitted between the ear portion 301 and the outer box body 1, and an air inlet groove corresponding to the air inlet box 3 is arranged on the top of the outer box body 1 4. Four arc-shaped fixing plates 5 are symmetrically welded at the top of the outer box 1 and the inner top of the air inlet box 3, and a wet curtain is fixed between the four fixing plates 5 Carton 6, honeycomb-shaped ventilation holes 601 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com