Preparation method of low-ester pectin stable emulsion

A low-ester pectin, emulsion technology, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of affecting the stability of the emulsion, inactivation of active ingredients, coalescence and flocculation, etc., to improve the stability. As well as bioavailability, enhance antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

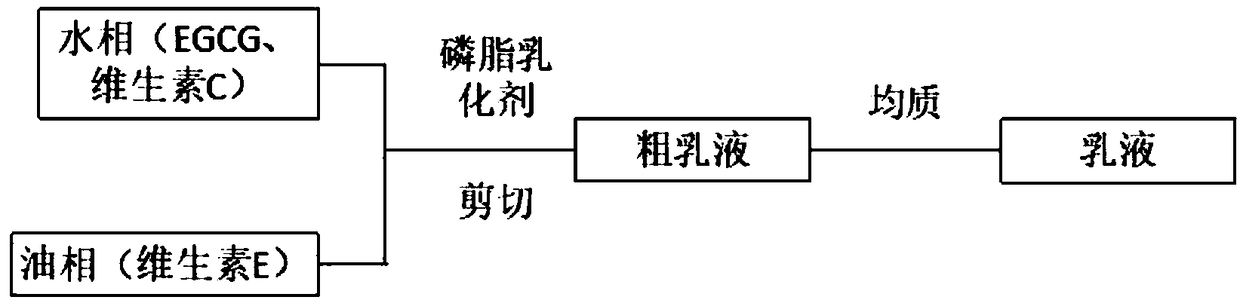

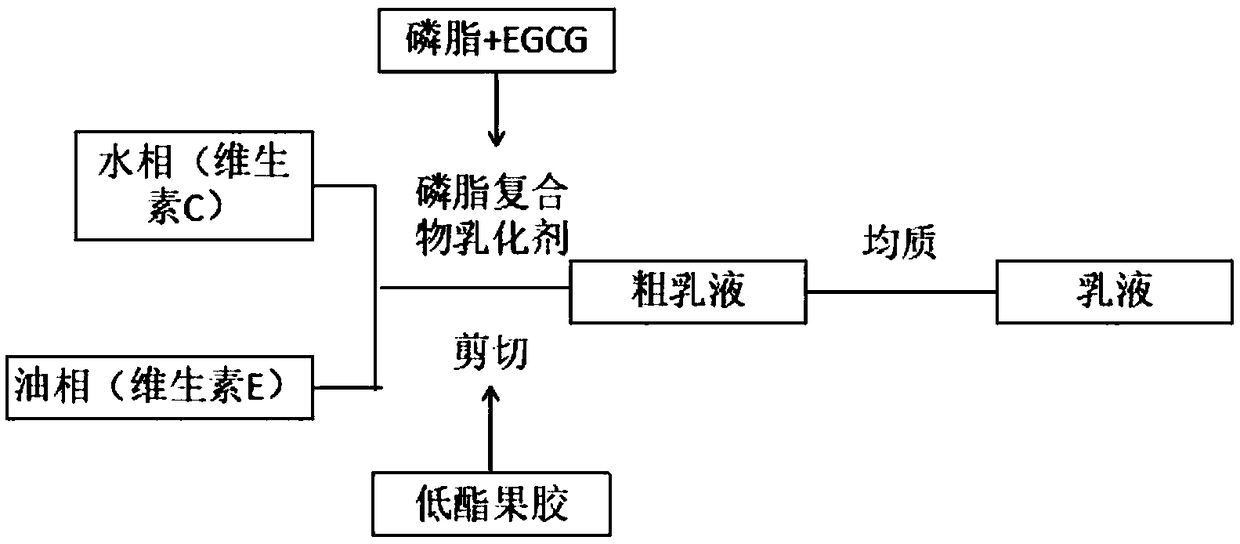

Method used

Image

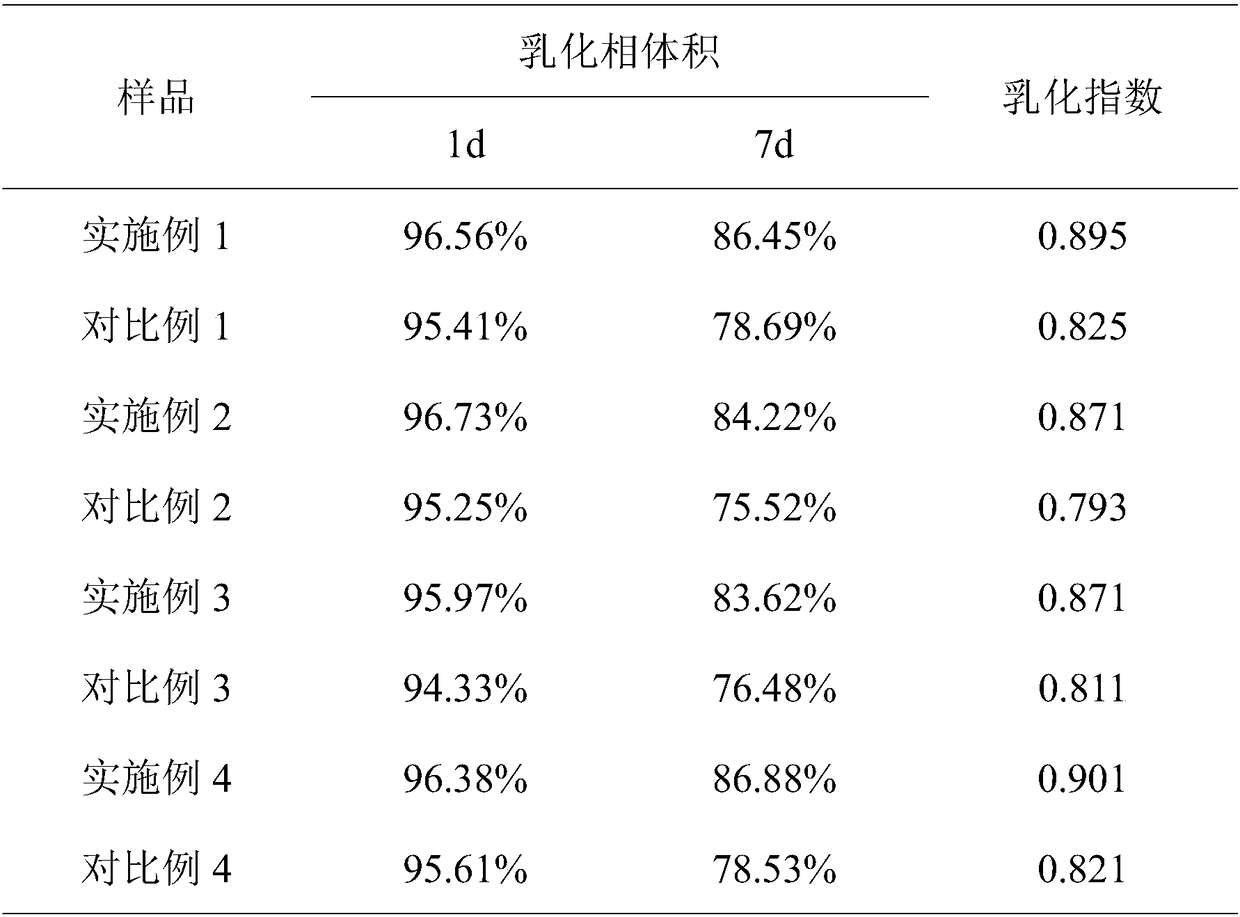

Examples

Embodiment 1

[0025] Pretreatment: Mix 1g EGCG and 0.8g phospholipid, add 20ml of distilled water, rotate and stir at room temperature until the reaction solution is clear and transparent, concentrate under reduced pressure to 5ml, add petroleum ether, leave it overnight, collect the solid by filtration and freeze-dry to obtain EGCG phospholipid Complex.

[0026] Preparation of emulsion: 100mL soybean oil containing 0.5g vitamin C was used as oil phase, 700mL distilled water containing 0.5g vitamin E was used as water phase, 1g EGCG phospholipid complex and 100mL oil phase were added to 700mL water phase, and then mass The fraction is 0.2% low-ester pectin aqueous solution 300mL, using a high-speed shearer, shearing at a speed of 25000r / min for 3min, to obtain a coarse emulsion. The crude emulsion was further treated with a high-pressure homogenizer and circulated twice at 80 MPa to obtain a low-ester pectin emulsion.

Embodiment 2

[0031] Pre-treatment: Mix 1g EGCG and 0.9g phospholipid, add 20ml of distilled water, rotate and stir at room temperature until the reaction solution is clear and transparent, concentrate under reduced pressure to 5ml, add petroleum ether, leave it overnight, collect by filtration and freeze-dry to obtain EGCG phospholipid Complex.

[0032] Preparation of emulsion: take 100mL soybean oil mixed with 0.5g vitamin C as the oil phase, take 800mL distilled water mixed with 0.5g vitamin E as the water phase, add 1g EGCG phospholipid complex and 100mL oil phase to the 800mL water phase, and then add mass 350 mL of low-ester pectin aqueous solution with a fraction of 0.3% was sheared at a speed of 25,000 r / min for 3 min with a high-speed shear to obtain a coarse emulsion. The crude emulsion was further treated with a high-pressure homogenizer and circulated twice at 80 MPa to obtain a low-ester pectin emulsion.

Embodiment 3

[0037] Pretreatment: Mix 1g EGCG and 1g phospholipid, add 20ml of distilled water, rotate and stir at room temperature until the reaction solution is clear and transparent, concentrate under reduced pressure to 5ml, add petroleum ether, leave it overnight, collect by filtration and freeze-dry to obtain EGCG phospholipid complex thing.

[0038]Preparation of the emulsion: take 100mL soybean oil mixed with 0.5g vitamin C as the oil phase, and 900mL distilled water mixed with 0.5g vitamin E as the water phase, add 1g EGCG phospholipid complex and 100mL oil phase to the 900mL water phase, and then add mass 400 mL of low-ester pectin aqueous solution with a fraction of 0.4% was sheared for 3 min at a speed of 25,000 r / min by a high-speed shearer to obtain a coarse emulsion. The crude emulsion was further treated with a high-pressure homogenizer and circulated twice at 80 MPa to obtain a low-ester pectin emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com