Preparation and application of nitrogen-doped porous carbon material

A technology for nitrogen-doped porous carbon and nitrogen compounds, applied in the field of porous materials, can solve problems such as waste, and achieve the effects of simple preparation process, high added value, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Step 1) Wash the ginkgo leaves, cut them into pieces, dry them, place them in a tube furnace at 500 °C, and carbonize them at a low temperature for 2 hours. Filter, wash, dry, and grind the carbonized products to obtain nitrogen-doped carbon Material;

[0040] Step 2) Mix the carbon precursor with KOH and urea at a mass ratio of 1.0:3.0:1.0, soak in 30ml deionized water, stir magnetically for 2 hours, dry and put it into a tube furnace for calcination under nitrogen protection. The calcination activation temperature was 700℃, the heating rate was 3℃, and the calcination activation time was 2 h to obtain nitrogen-doped porous activated carbon materials;

[0041] Step 3) The above product was soaked in 1M HCl solution, washed with deionized water, filtered until neutral, dried and ground to obtain a nitrogen-doped porous carbon material.

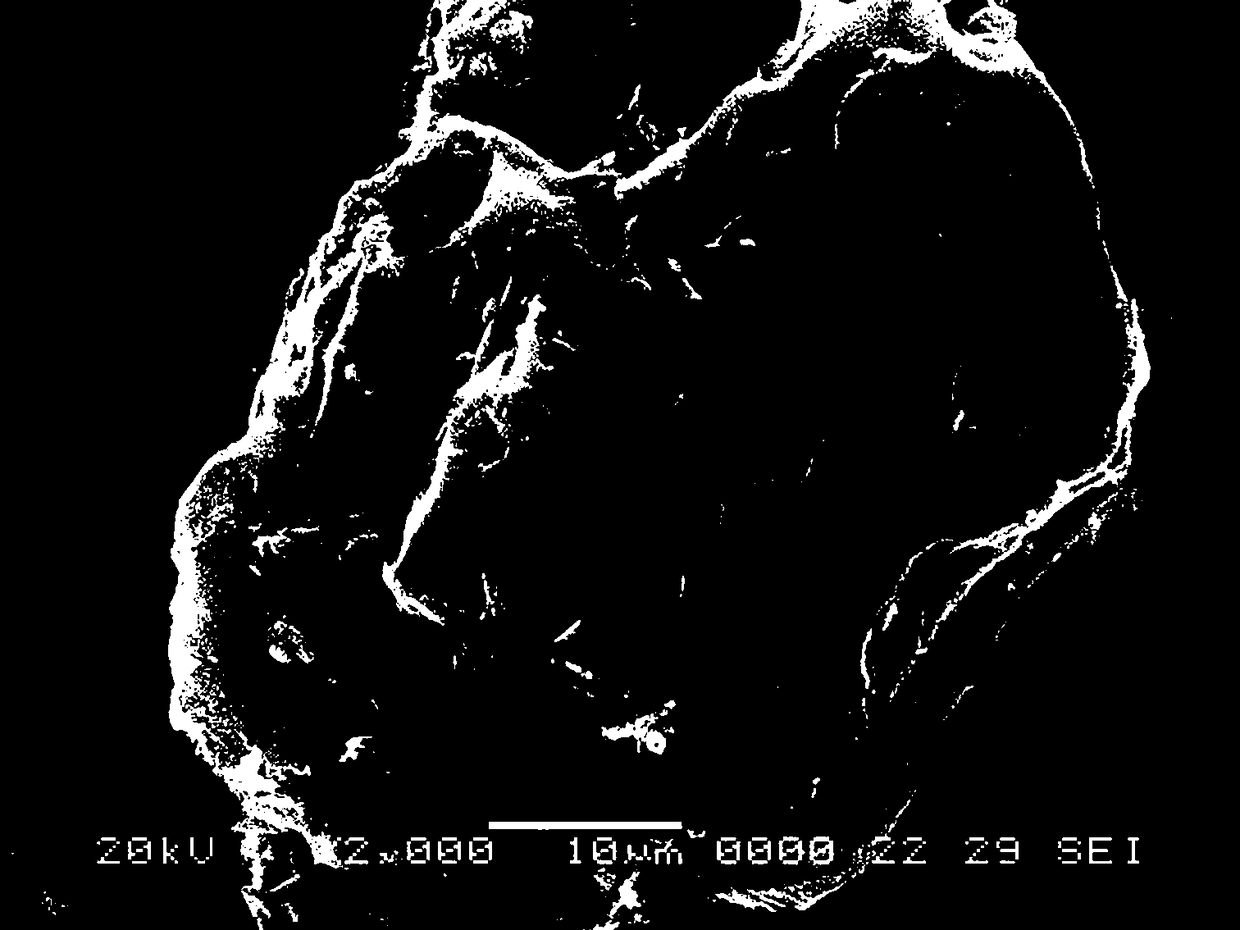

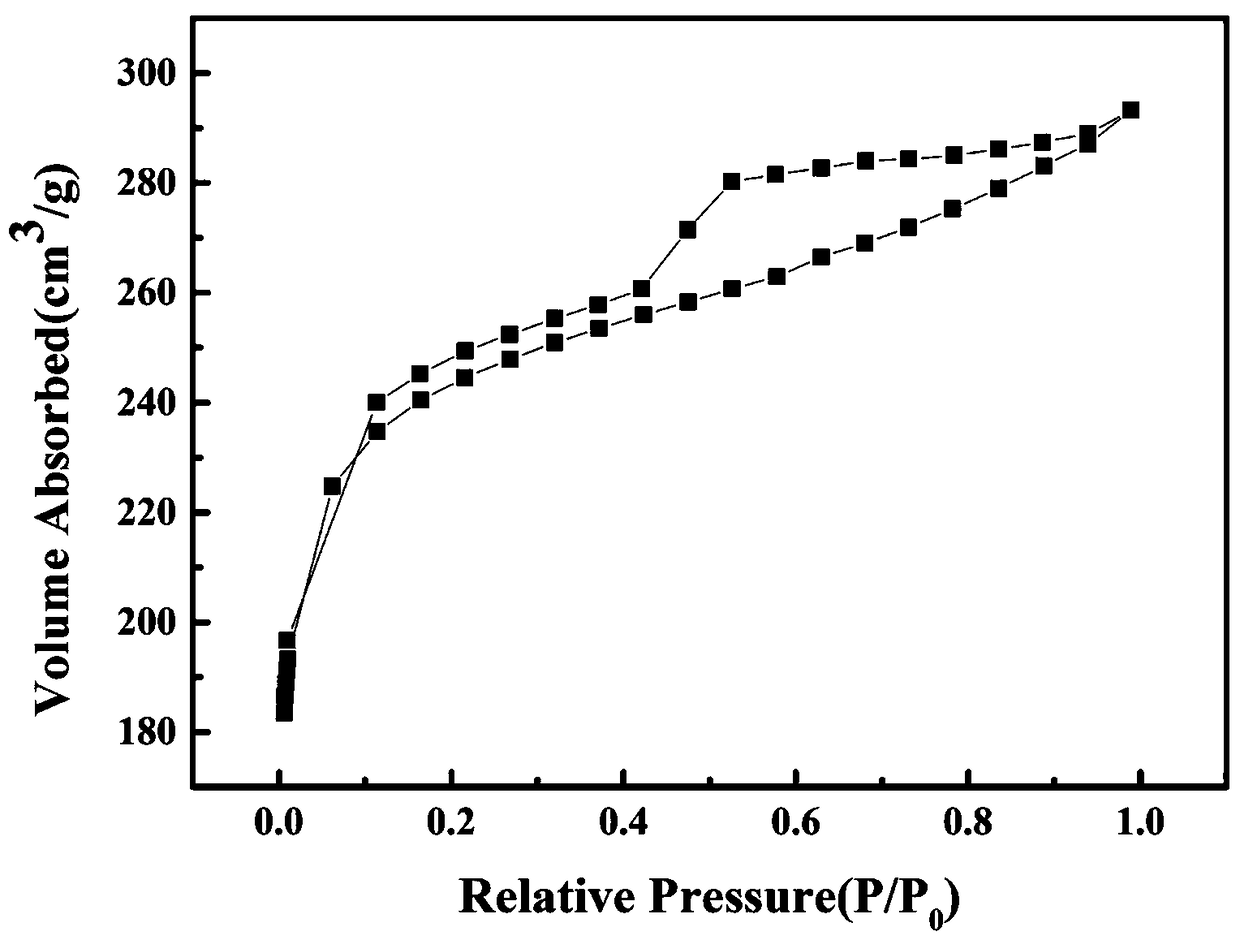

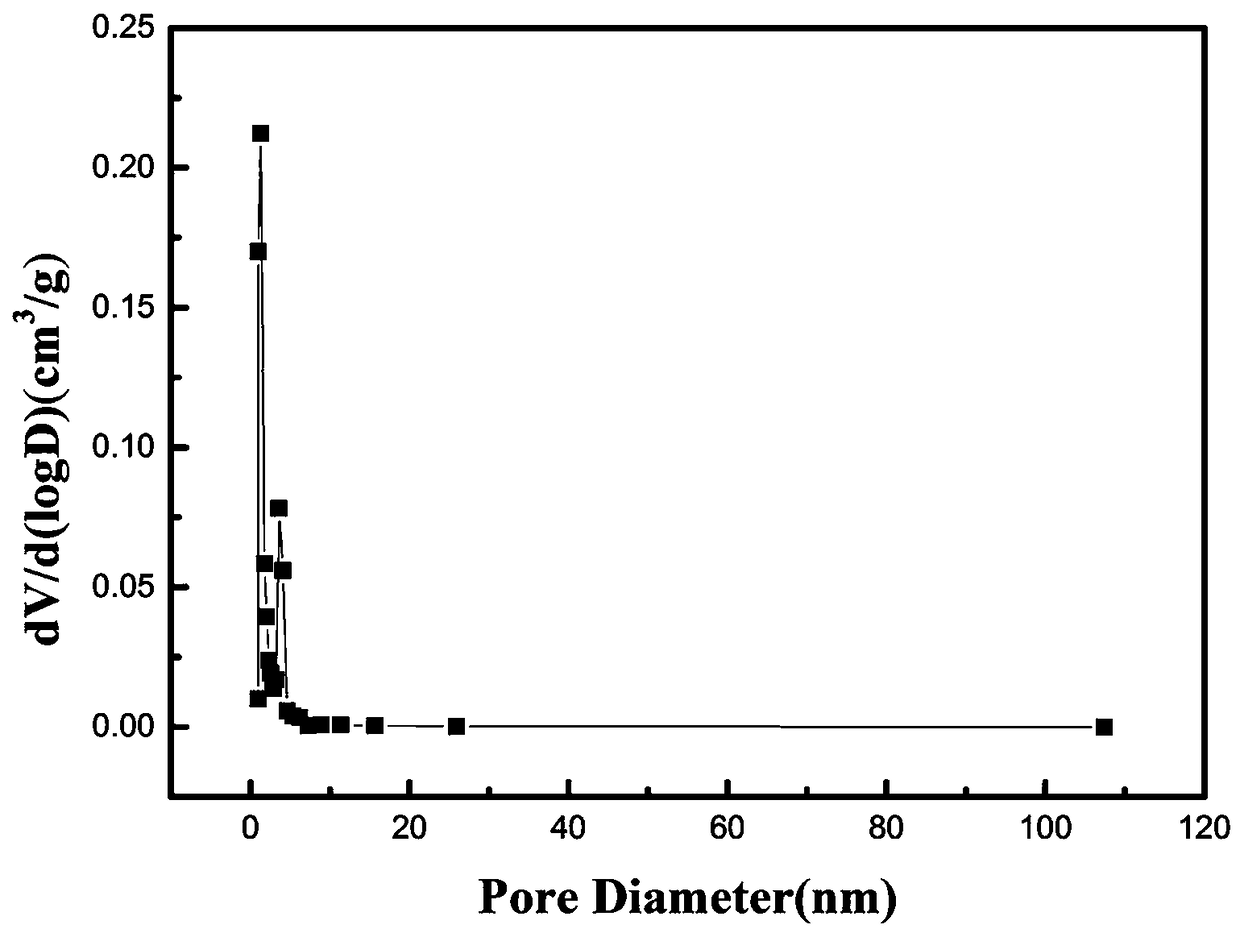

[0042] The nitrogen-doped porous carbon material prepared in the embodiment is tested by scanning electron microscope, and the result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com