Halogen-free flame-retardant low-pressure packaging material with ultra-low dielectric property and preparation method thereof

A technology of ultra-low dielectric and packaging materials, which is applied in the field of ultra-low dielectric properties, halogen-free flame-retardant low-voltage packaging materials and its preparation, and can solve the problems of inapplicability of injection molded parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the halogen-free flame-retardant low-voltage packaging material with ultra-low dielectric properties comprises the following steps:

[0053] 1) Under a protective atmosphere, dissolve dimer acid, dibasic acid, diamine and polyetherdiamine in a reactor, and form a salt at 20°C to 100°C;

[0054] 2) Add phosphoric acid, disperse evenly, heat up to 150°C-180°C, and react under stirring at 300r / min-800r / min for 0.2h-2h;

[0055] 3) Continue to heat up to 200°C to 250°C, vacuum the reaction system to <30mbar, and react for 0.2h to 2h under stirring at a speed of 50r / min to 300r / min to obtain a dimer acid type polyamide prepolymer;

[0056] 4) Add bifunctional polyphenylene ether, disperse evenly, cool down to 150°C-200°C, add dibutyltin laurate and diisocyanate, and continue to react for 1h-3h to obtain dimer acid type polyamide material;

[0057] 5) Continue to add halogen-free flame retardant, antioxidant, hydrolysis stabilizer, UV stabilizer and...

Embodiment 1

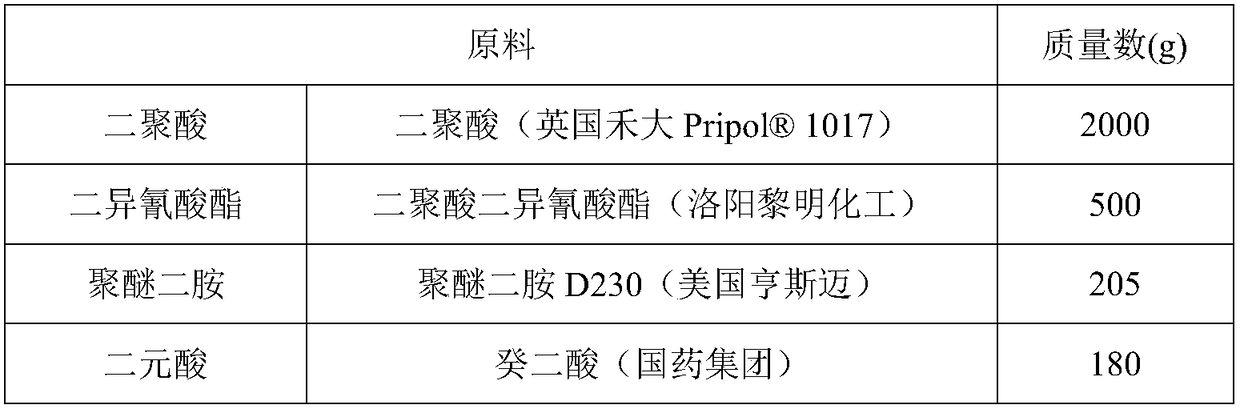

[0072] A halogen-free flame-retardant low-voltage packaging material with ultra-low dielectric properties, the composition of which is shown in Table 1.

[0073] Table 1 Example 1 Formula composition of ultra-low dielectric performance halogen-free flame-retardant low-voltage packaging material

[0074]

[0075]

[0076] Example 1 The preparation method of an ultra-low dielectric performance halogen-free flame-retardant low-voltage packaging material includes the following steps:

[0077] 1) Under the protection of nitrogen gas, dissolve dimer acid, sebacic acid, ethylenediamine, and polyetherdiamine in an 8L reactor, and raise the temperature to 60°C to form a salt.

[0078] 2) After adding the phosphoric acid catalyst and dispersing evenly, raise the temperature to 160°C and react for 1 hour under rapid stirring at 600r / min.

[0079] 3) Continue to increase the temperature to 230°C, keep the temperature constant, and vacuumize the reaction system to 20mbar, then maint...

Embodiment 2

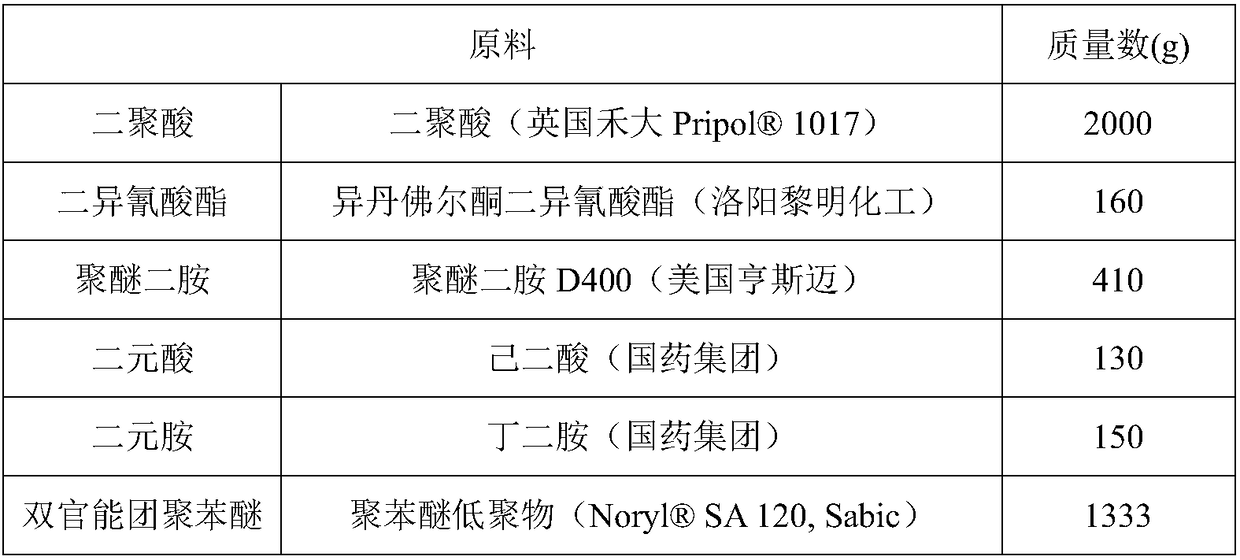

[0083] A halogen-free flame-retardant low-voltage packaging material with ultra-low dielectric properties, the composition formula of which is shown in Table 2.

[0084] Table 2 Example 2 Formula composition of ultra-low dielectric performance halogen-free flame-retardant low-voltage packaging material

[0085]

[0086]

[0087] Example 2 The preparation method of an ultra-low dielectric performance halogen-free flame-retardant low-voltage packaging material includes the following steps:

[0088] 1) Under the protection of helium gas, dissolve dimer acid, adipic acid, butylenediamine, and polyetherdiamine in a 6L reactor, and raise the temperature to 70°C to form a salt.

[0089] 2) After adding the phosphoric acid catalyst and dispersing evenly, raise the temperature to 170°C and react for 1.5h under rapid stirring at 700r / min.

[0090]3) Continue to raise the temperature to 240°C, keep the temperature constant, and vacuumize the reaction system to 30mbar, then maintai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amine value | aaaaa | aaaaa |

| Amine value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com