Method for treating nickel-chromium-contained hazardous waste through rotary kiln electric furnace (RKEF) process

A nickel-chromium and process technology, which is applied in the field of nickel-chromium-containing hazardous waste treatment, can solve problems such as poor economy, long treatment process, environmental hazards, etc., to achieve sustainable development, solve solid waste treatment problems, The effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described below.

[0024] The present invention provides a method for treating nickel-chromium-containing hazardous waste by using the RKEF process. Now, the process of the present invention is described by taking production in a φ5×40m drying kiln, a φ4.4×100m rotary kiln, and a 33000KVA submerged arc furnace as examples. step:

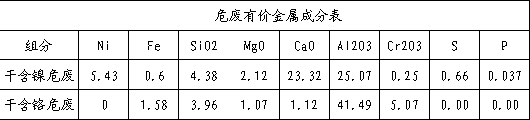

[0025] (1) Store the recycled nickel-chromium-containing hazardous waste in the indoor wet ore yard, make a hard bottom and store it separately, and set up a canopy. At present, there are two types of aluminum alloy solid waste, and the sample composition table after drying is as follows:

[0026]

[0027] (2) Wet ore batching: The aluminum alloy hazardous waste is mixed into the laterite-nickel ore wet ore at a proportion of 5% on a dry basis; the aforementioned percentage is the percentage of the hazardous waste in the total mass of the nickel-chromium-containing hazardous waste and the laterite-nickel or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com