Wear-resistant and corrosion-resistant high-chromium iron-based amorphous alloy and preparation method thereof

A technology for iron-based amorphous alloys and amorphous alloys, applied in the field of iron-based amorphous alloys, can solve problems such as unfavorable industrial application, unfavorable application at high temperatures, and reduced thermal stability, and achieve excellent friction and wear resistance and corrosion resistance. Excellent performance and the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The main component of the iron-based amorphous alloy of the present embodiment is (Fe 0.9 Ni 0.1 ) 36 Cr 23 Mo 18 B 6 Y 2 , wherein the content of three atomic percentages (at%) of Fe, Cr and Mo are respectively 32.5±0.4, 23.0±0.7, 18.0±0.2.

[0037] The specific preparation method is as follows:

[0038] First press (Fe 0.9 Ni 0.1 ) 36 Cr 23 Mo 18 (C 0.9 P 0.1 ) 15 B 6 Y 2 The mass ratio of the amorphous alloy is used for batching;

[0039] Then, under the condition of evacuating the prepared raw materials and filling them with high-purity argon gas, the titanium ingots are arc smelted to purify the gas in the furnace, and the raw materials are smelted repeatedly for more than 5 times by adding magnetic stirring to obtain a uniform composition. alloy ingot;

[0040] Finally, put the alloy ingot above the copper mold for suction casting, heat the alloy ingot with an electric arc until it is completely melted and keep it warm for 10-20s, open the valve ...

Embodiment 2

[0044] The main component of the iron-based amorphous alloy of this embodiment is Fe 32 Cr 25 Mo 20 (C 0.9 P 0.1 ) 15 B 6 Y 2 , where the content of three atomic percentages (at%) of Fe, Cr and Mo are respectively 32.0±0.4, 25.0±0.5, and 20.0±0.2.

[0045] 4mm alloy rods were prepared using the test method described in Example 1.

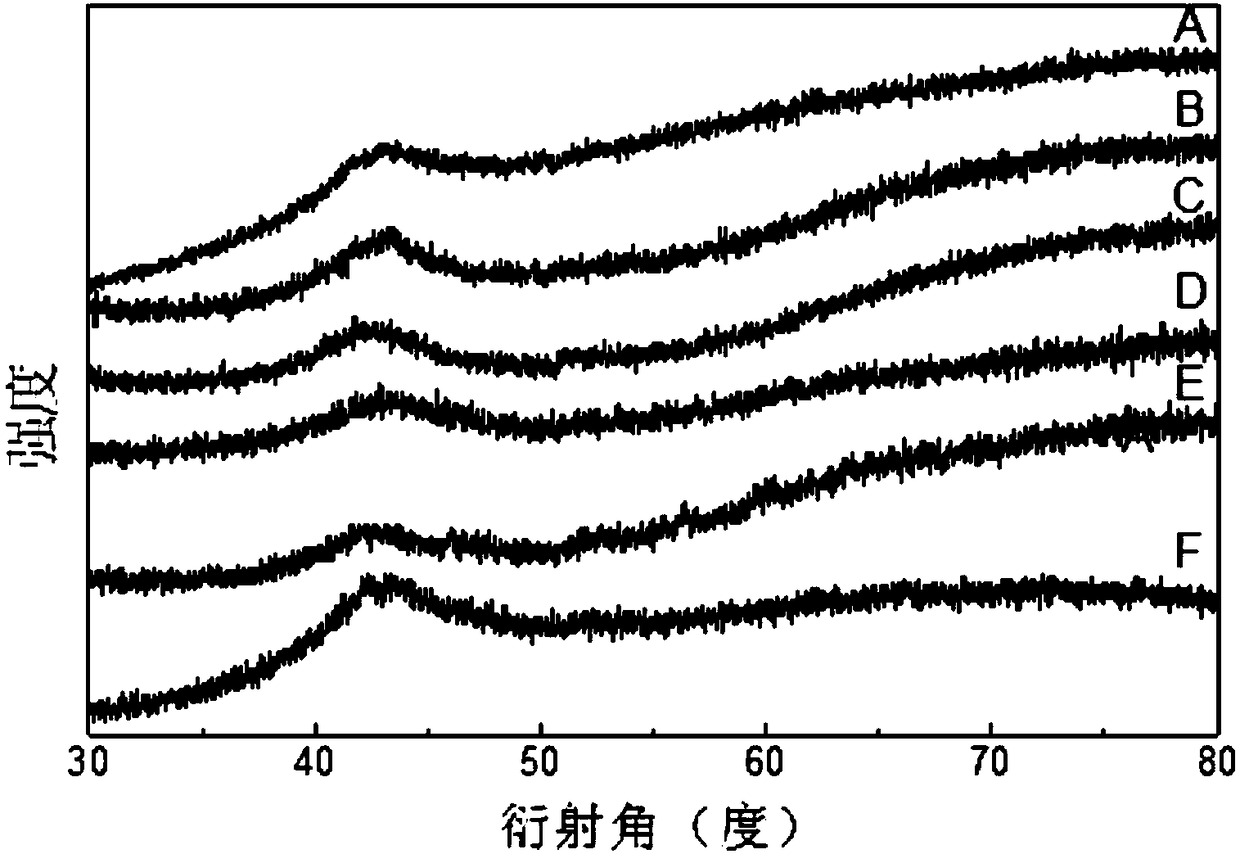

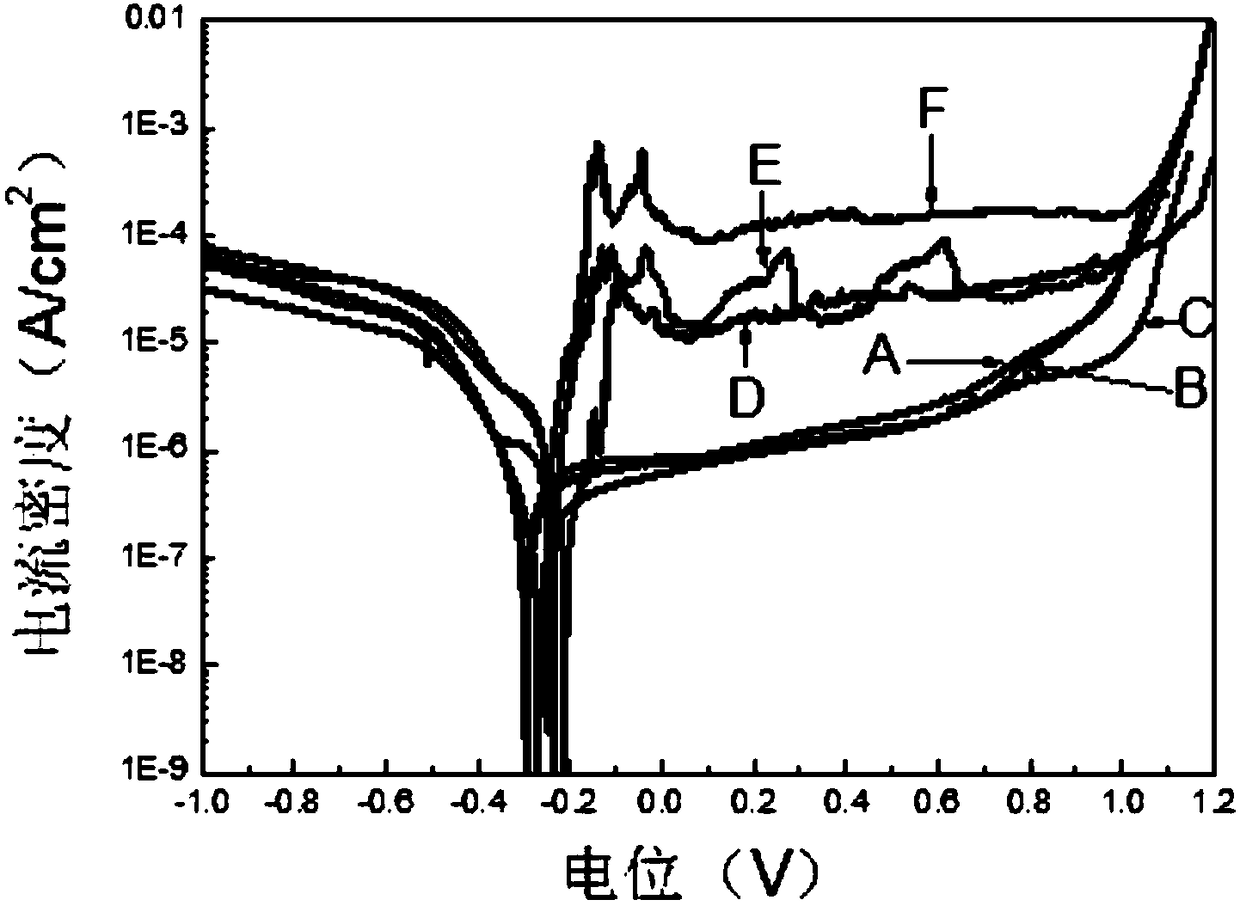

[0046] The XRD of the 4mm diameter sample that present embodiment provides (as figure 1 (B)) shows that it has a fully amorphous structure; DSC analysis shows that the system has high thermal stability, the glass transition temperature Tg reaches 905K, the crystallization initiation temperature Tx reaches 955K, the original system Tg is 838K, and Tx is 896K; the system Excellent corrosion resistance, the corrosion rate in aqua regia is only 0.67mm / a, the corrosion rate in 3.5wt.% NaCl solution is only 0.0004mm / a, and the passivation current density is 2~5*10 -6 A / cm 2 (Such as figure 2 (B)), the corrosion rate of the original system in a...

Embodiment 3

[0048] The main component of the iron-based amorphous alloy of this embodiment is Fe 28 Cr 27 Mo 22 (C 0.9 P 0.1 ) 15 B 6 Y 2 , wherein the content of three atomic percentages (at%) of Fe, Cr and Mo are respectively 28.0±0.4, 27.0±0.5, 22.0±0.2.

[0049] 4mm alloy rods were prepared using the test method described in Example 1.

[0050] The XRD of the 4mm diameter sample that present embodiment provides (as figure 1 (C)) shows that it has a fully amorphous structure; DSC analysis shows that the system has high thermal stability, the glass transition temperature Tg reaches 910K, the crystallization initiation temperature Tx reaches 959K, the original system Tg is 838K, and Tx is 896K; the system Excellent corrosion resistance, the corrosion rate in aqua regia is only 0.58mm / a, the corrosion rate in 3.5wt.% NaCl solution is only 0.00035mm / a, and the passivation current density is 2~5*10 -6 A / cm2 (Such as figure 2 (C)), the corrosion rate of the original system in NaCl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Passivation current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com