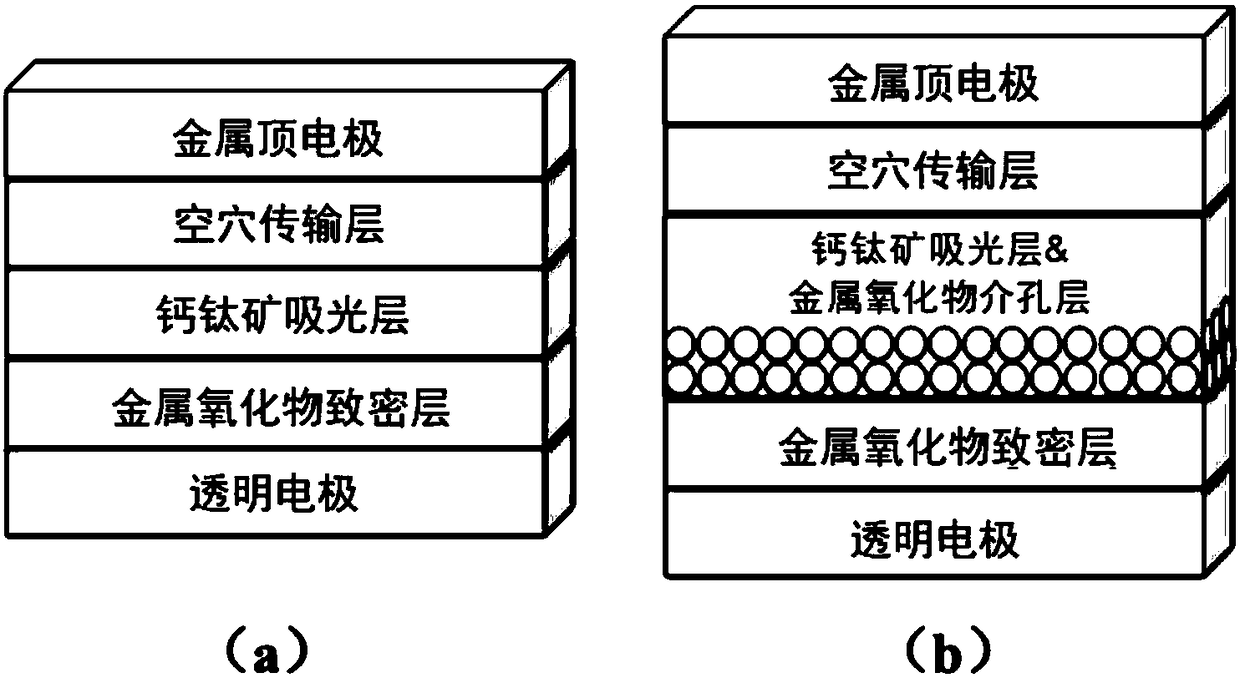

United boron compound modification-based perovskite type solar cell and preparation method thereof

A solar cell, perovskite-based technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complex process, high cost, restricting the development of perovskite-based solar cell technology, etc. Conducive to transmission, reducing the effect of interface recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

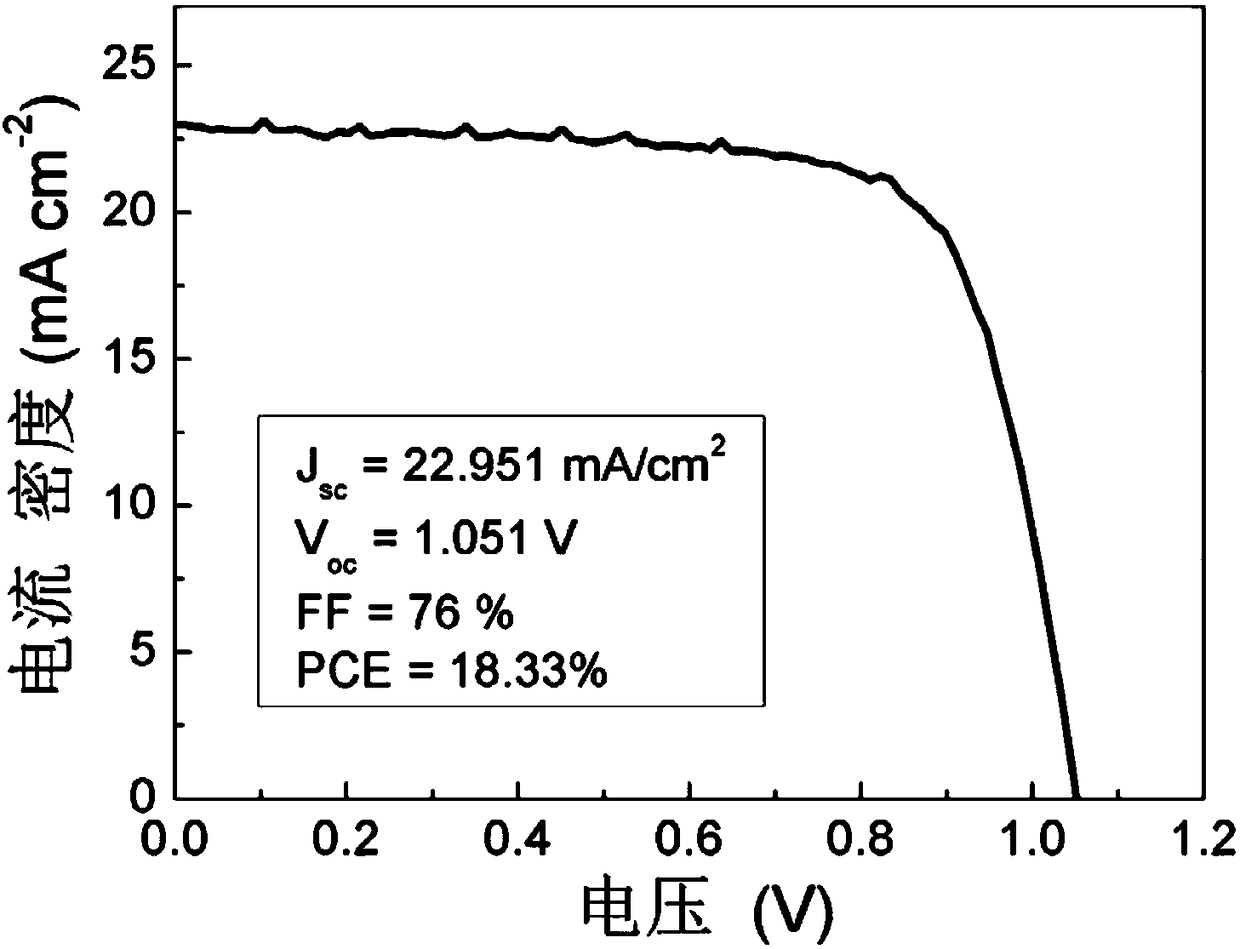

Embodiment 1

[0031] In the first step, use deionized water, acetone, optical glass cleaner, deionized water, and isopropanol to ultrasonically clean the FTO glass substrate (15Ω / □), dry it in an oven at 60°C for 4 hours, and then spin-coat it on the FTO surface TiO at a concentration of 5 mg / mL 2 Colloidal quantum dots, wherein the solvent used is a mixed solvent of methanol:chloroform=1:1 (volume ratio). The rotation speed of spin coating is 4000rpm, the spin coating time is 20s, and the acceleration is 2000rpm / s. Subsequently, the substrate was heated and annealed at 150° C. for 30 minutes.

[0032] In the second step, the TiO 2 Thin film substrate transferred to N 2 Atmosphere glove box, and immersed in the prepared C with a concentration of 10mg / mL 12 h 24 B 2 o 4 Soak in isopropanol solution at room temperature for 24 hours, fully adsorb C 12 h 24 B 2 o 4 on TiO 2 The surface of the film was washed with isopropanol solvent to remove excess C 12 h 24 B 2 o 4 . Transfer...

Embodiment 2

[0035] In the second step, the TiO 2 Thin film substrate transferred to N 2 Atmosphere glove box, and immersed in the prepared C with a concentration of 10mg / mL 10 h 20 B 2 o 4 Soak in isopropanol solution at room temperature for 24 hours, fully adsorb C 10 h 20 B 2 o 4 on TiO 2 The surface of the film was washed with isopropanol solvent to remove excess C 10 h 20 B 2 o 4 . Transfer the film substrate to a hot stage at 80°C and heat for 30 minutes to obtain a surface rich in Ti 3+ TiO 2 film. The preparation method of all the other steps is the same as that of Example 1. The photoelectric conversion efficiency of such perovskite solar cells can reach ∼17%.

Embodiment 3

[0037] In the second step, the TiO 2 Thin film substrate transferred to N 2 Atmosphere glove box, and immersed in the prepared B with a concentration of 10mg / mL 2 (OH) 4 Soak in isopropanol solution at room temperature for 24 hours, fully adsorb B 2 (OH) 4 on TiO 2 The surface of the film was washed with isopropanol solvent to remove excess B 2 (OH) 4 . Transfer the film substrate to a hot stage at 80°C and heat for 30 minutes to obtain a surface rich in Ti 3+ TiO 2 film. The preparation method of all the other steps is the same as that of Example 1. The photoelectric conversion efficiency of such perovskite solar cells can reach ∼17%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com