Process and production line for preparing tailing functional material

A functional material and production line technology, applied in cement production, climate sustainability, sustainable waste treatment, etc., can solve problems such as environmental pollution and resource waste, and achieve the effect of promoting the ecological environment, controlling pollution, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

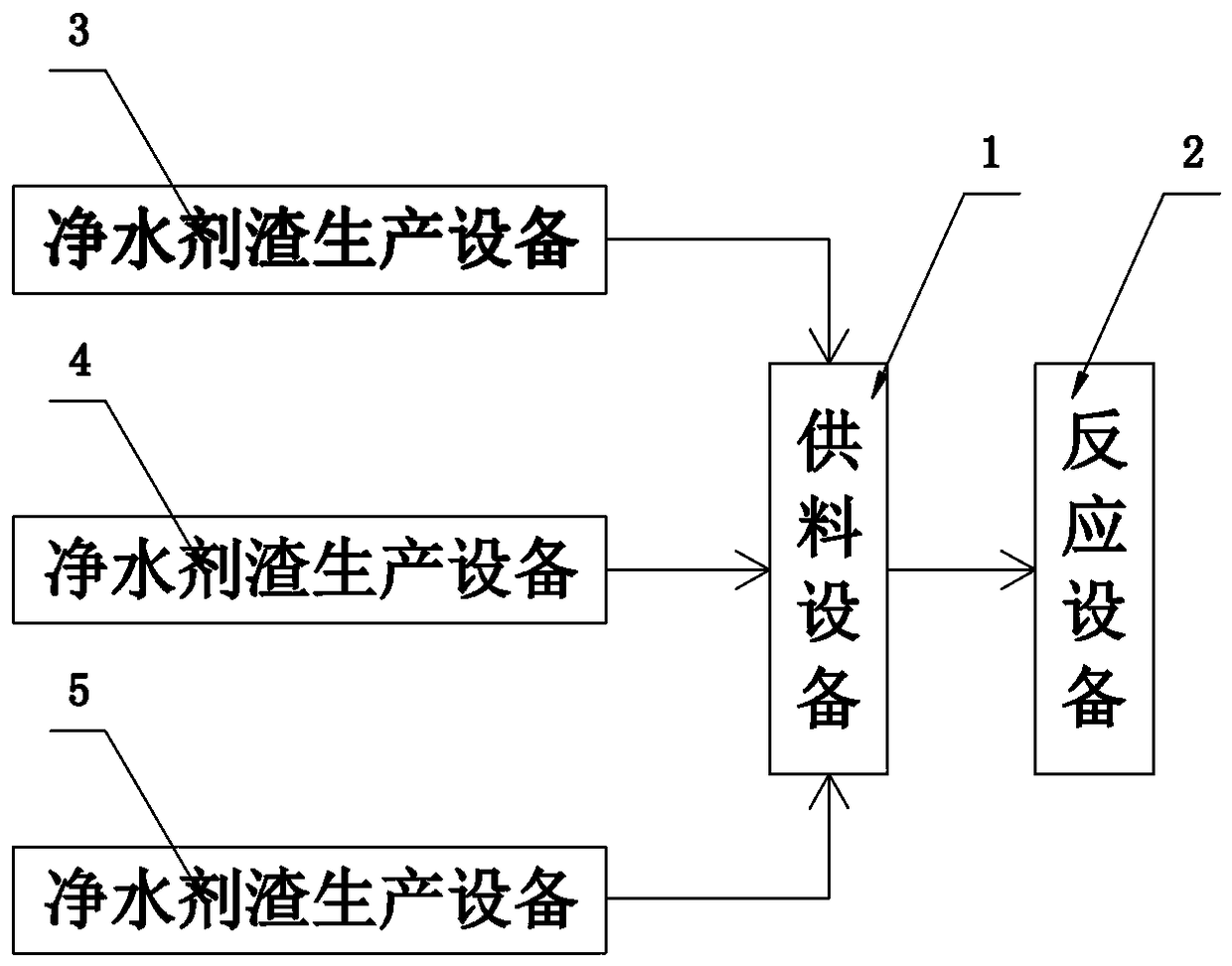

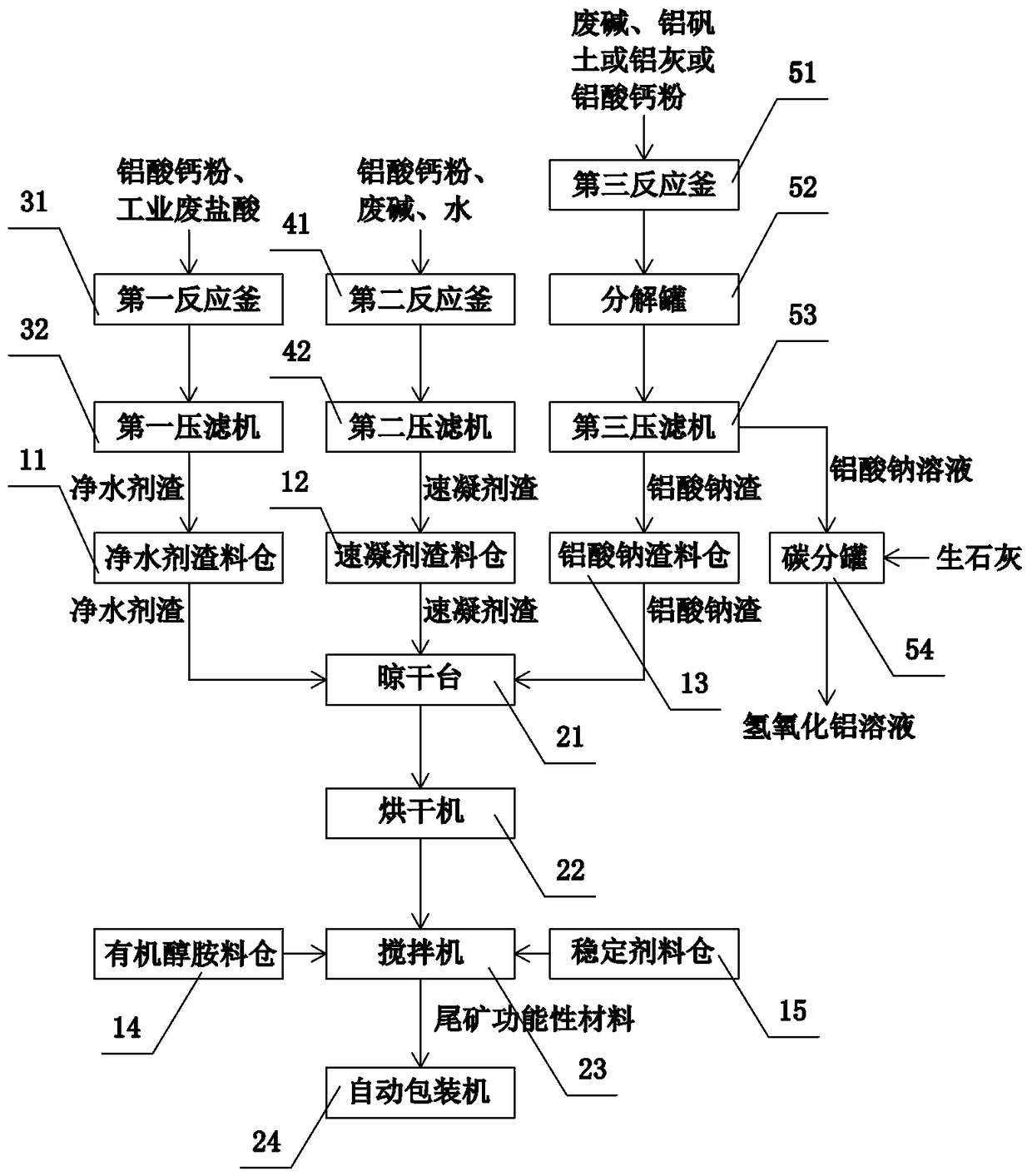

[0028] refer to figure 1 , figure 2 . A production line for preparing tailings functional materials, including feeding equipment 1, reaction equipment 2, water purifying agent slag production equipment 3, quick-setting agent slag production equipment 4, and sodium aluminate slag production equipment 5. in,

[0029] The feeding equipment 1 includes a water purifying agent slag silo 11 for accommodating water purifying agent slag, an accelerator slag silo 12 for accommodating accelerator slag, and an alumina acid silo for accommodating sodium aluminate slag. Sodium slag storage bin 13, organic alcohol amine storage bin 14 for accommodating organic alcohol amine, and stabilizer storage bin 15 for accommodating stabilizer.

[0030] Reaction equipment 2 comprises the drying platform 21 that connects water purifier slag silo 11, quick-setting agent slag si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com