A deep-water water-based drilling fluid and its application

A water-based drilling fluid and deep-water water-based technology, which can be used in underwater drilling, earth-moving drilling, flushing wells, etc., and can solve problems such as reservoir damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] In terms of mass percentage, the deep-water water-based drilling fluid provided by the present invention includes 0.5% to 3.5% fluid loss control agent, more preferably 1% to 3.0%. In the present invention, the fluid loss control agent is preferably modified starch. In the present invention, the preparation method of the fluid loss control agent preferably includes:

[0026] Mix the starch raw material, alkali, haloacetic acid and water, and carry out modification reaction to obtain the mixture;

[0027] Expanding and modifying the mixture at 95-105°C to obtain expanded starch;

[0028] The expanded starch is refined to obtain modified starch.

[0029] In the present invention, the starch raw material, alkali, halogenated acetic acid and water are preferably mixed to obtain a mixture. In the present invention, in terms of parts by mass, the starch raw material in the mixture preferably includes 80-110 parts, more preferably 88-103 parts. In the present invention, th...

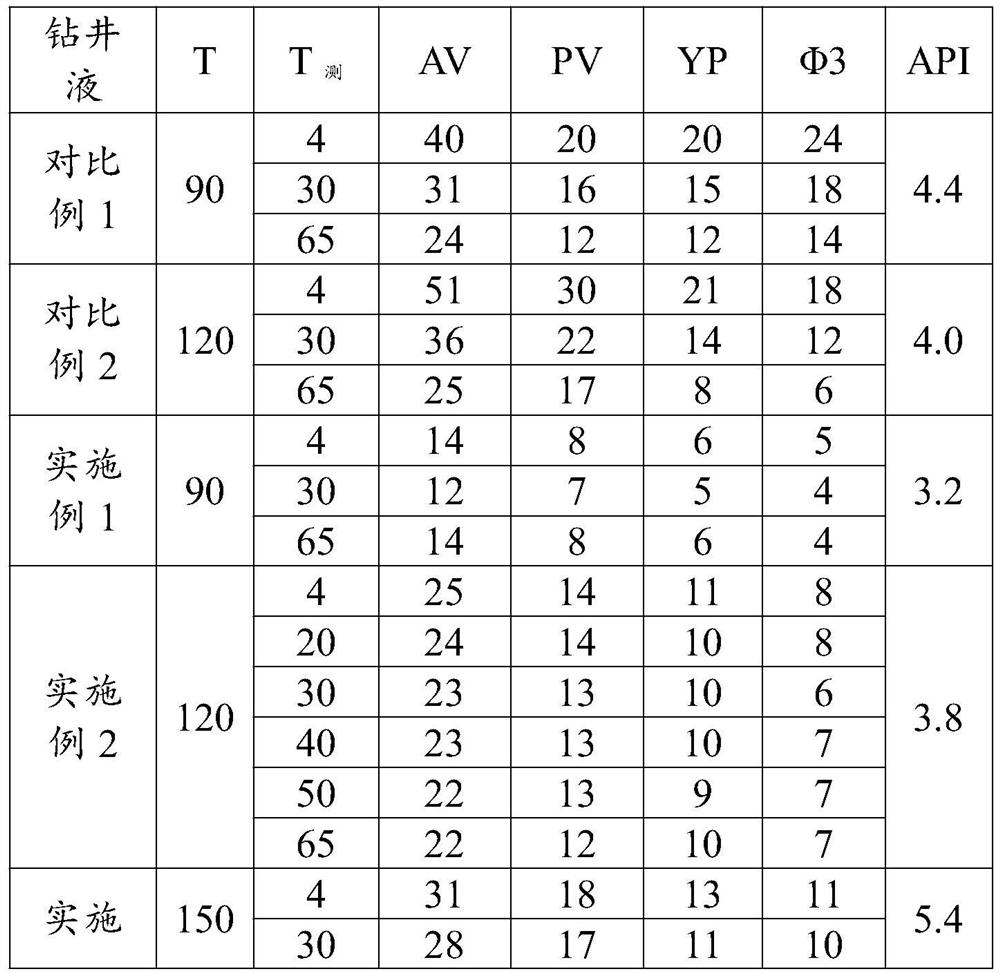

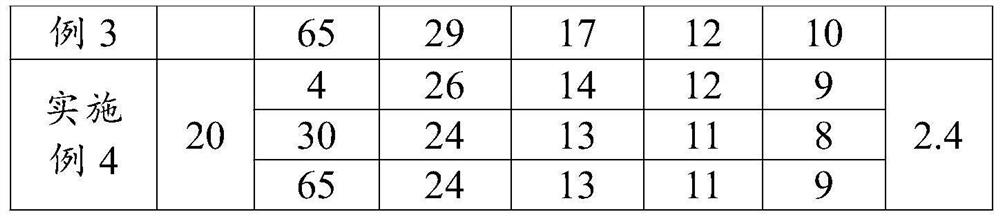

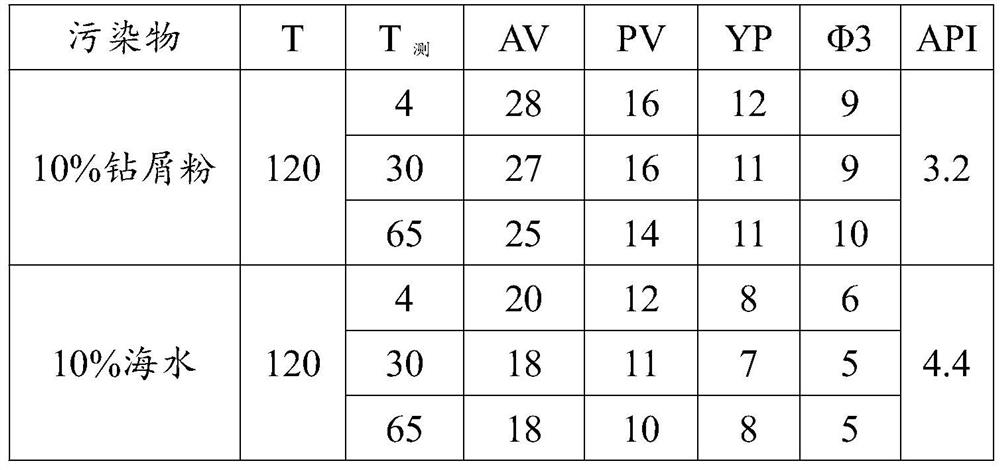

Embodiment 1

[0048] In terms of mass percentage, the composition of deepwater water-based drilling fluid: 0.1% viscosifier, 0.1% alkalinity regulator, 3.5% fluid loss control agent, 1.5% low temperature flow pattern regulator, 5.0% shale inhibitor, 15% % hydrate inhibitor, 1.0% lubricant, 10.0% temporary plugging agent and the balance of seawater, of which:

[0049] Thickener: xanthan gum, coriander gum, konjac gum, guar gum and thorny bean gum are mixed at a mass ratio of 40:20:10:5;

[0050] Alkalinity regulator: sodium hydroxide;

[0051] Filtrate reducer: modified starch, prepared according to the following method: 50 parts by mass of potato starch, 20 parts by mass of tapioca starch, 20 parts by mass of canna starch, 1 part by mass of sodium hydroxide, 5 parts by mass of haloacetic acid and 150 parts by mass of After mixing parts by mass of deionized water evenly, pour it into the screw extruder, control the temperature at 100°C, extrude the raw material mixture from the outlet of th...

Embodiment 2

[0060] In terms of mass percentage, the composition of deepwater water-based drilling fluid: 0.5% viscosifier, 0.5% alkalinity regulator, 1.5% fluid loss reducer, 0.5% low temperature flow pattern regulator, 1.0% shale inhibitor, 25% % hydrate inhibitor, 3.0% lubricant, 5.0% temporary plugging agent and the balance of seawater, of which:

[0061] Tackifier: xanthan gum;

[0062] Alkalinity regulator: sodium hydroxide and sodium carbonate are mixed according to the mass ratio of 1:3;

[0063] Filtrate reducer: modified starch: 40 parts by mass of potato starch, 30 parts by mass of tapioca starch, 30 parts by mass of canna starch, 2 parts by mass of sodium hydroxide, 10 parts by mass of haloacetic acid and 120 parts by mass of deionized water After uniformity, it was prepared according to the method of Example 1, except that the temperature of the screw extruder was controlled at 95°C;

[0064] Low temperature flow regulator: polyethylene glycol fatty acid ester;

[0065] Sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com