Preparation method, obtained material and application of photo/thermal dichromic fiber

A color-changing fiber and color-changing technology, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of unstable product performance, poor response sensitivity, complex process, etc., and achieve low cost, low cost, and process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

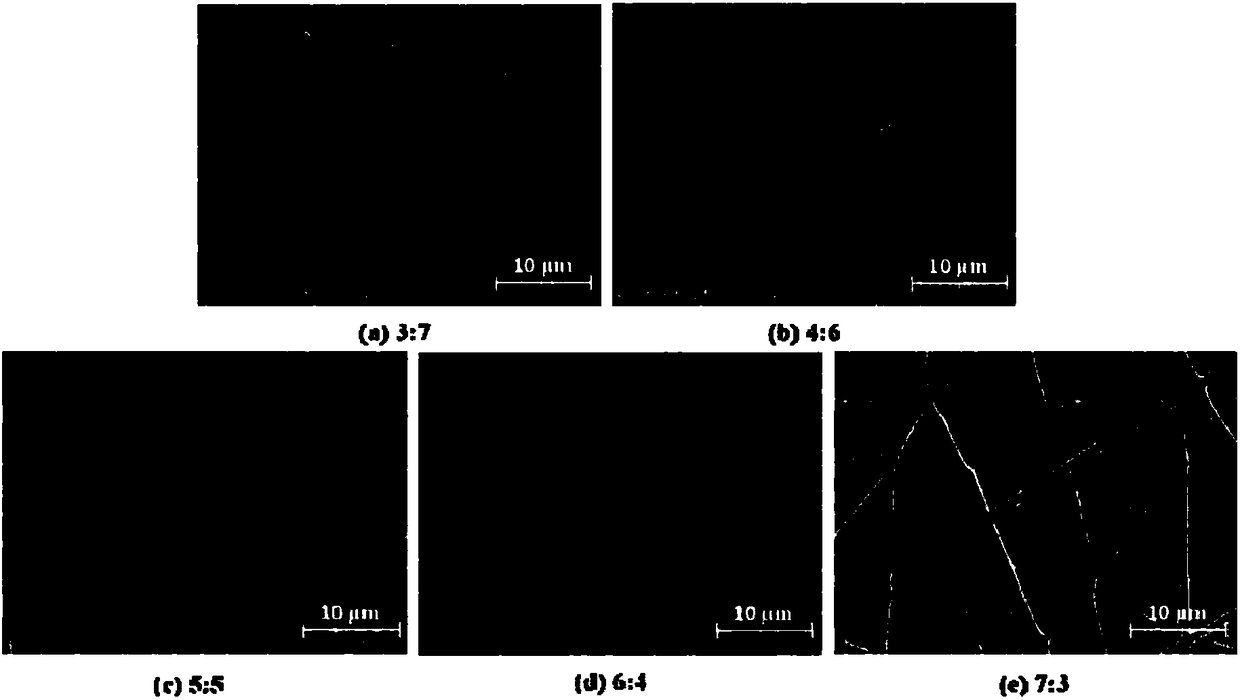

[0031] (1) Preparation of a uniform and stable spinning solution: under dark conditions, add a certain amount of 10,12-pentacosadiynoic acid (PCDA) to the dichloromethane / N,N'-dimethyl In a mixed solvent of formamide (1:1 / w:w), the ice bath was sonicated for 0.5 h to fully dissolve PCDA in dichloromethane. Polyethylene oxide (PEO) was mixed with thermosetting polyurethane at a ratio of 3:7, and after magnetic stirring at 70°C for 6 hours, it was dissolved in dichloromethane / N,N'-dimethylformamide (1:1 / w :w) in a mixed solvent to obtain a mixed solution. The above two mixed solutions are mixed in a certain ratio, and after being fully stirred, a uniform and stable spinning solution is obtained.

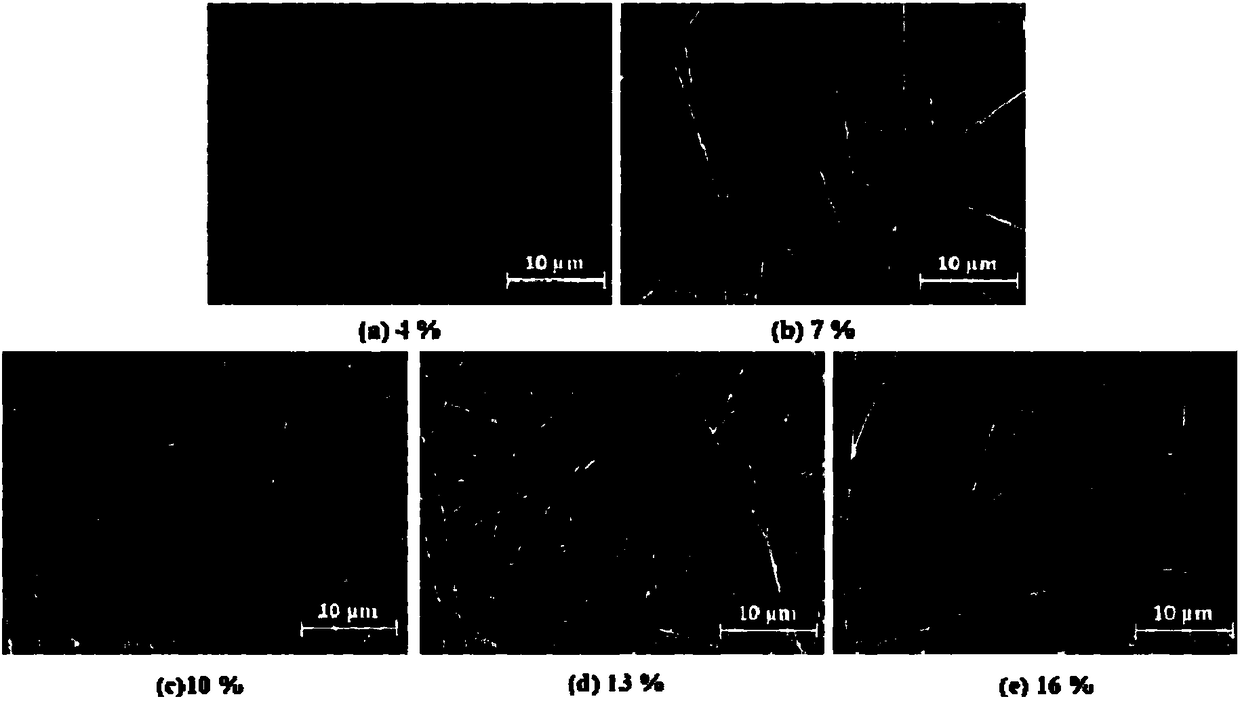

[0032] The concentration of the mixed polymer in the spinning dope is 10w%, and the concentration of the PCDA is 1w%.

[0033] (2) Electrospinning device using horizontal spinning. Take 3ml of spinning stock solution with a syringe, after standing to defoam, control the flow rate of...

Embodiment 2

[0036] (1) Prepare a uniform and stable spinning dope: under dark conditions, add a certain amount of 10,12-tracosadiynoic acid to dichloromethane / N,N'-dimethylformamide ( 1:1 / w:w) in a mixed solvent, sonicate in an ice bath for 0.5 h to fully dissolve PCDA in dichloromethane. Polymethyl methacrylate (PMMA) was mixed with thermosetting polyurethane at a ratio of 4:6, and after magnetic stirring at 70°C for 6 hours, it was dissolved in dichloromethane / N,N'-dimethylformamide (1:1 / w:w) in a mixed solvent to obtain a mixed solution. The above two mixed solutions are mixed in a certain ratio, and after being fully stirred, a uniform and stable spinning solution is obtained.

[0037] The concentration of the mixed polymer in the spinning dope is 13w%, and the concentration of the 10,12-tracosadiynoic acid is 1.5w%.

[0038](2) Electrospinning device using horizontal spinning. Take 3ml of spinning stock solution with a syringe, after standing for defoaming, control the flow rate ...

Embodiment 3

[0041] (1) Preparation of a uniform and stable spinning solution: under dark conditions, add a certain amount of 10,12-pentacosadiyn-1-ol to the dichloromethane / N,N'-dimethyl In a mixed solvent of formamide (1:1 / w:w), the ice bath was sonicated for 0.5 h to fully dissolve PCDA in dichloromethane. Mix polystyrene (PS) and thermosetting polyurethane at a ratio of 5:5, and dissolve it in dichloromethane / N,N'-dimethylformamide (1:1 / w:w ) in a mixed solvent to obtain a mixed solution. The above two mixed solutions are mixed in a certain ratio, and after being fully stirred, a uniform and stable spinning solution is obtained.

[0042] The concentration of mixed polymers in the spinning dope is 16w%, and the concentration of 10,12-pentacosadiyn-1-ol is 2w%.

[0043] (2) Electrospinning device using horizontal spinning. Take 3ml of spinning stock solution with a syringe, and after standing for defoaming, control the flow rate of spinning solution to 0.8ml / h, apply a working voltage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com