Nano-composite material with molybdenum trioxide@molybdenum disulfide core-shell heterostructure, and preparation method and application thereof

A nanocomposite material, molybdenum trioxide technology, applied in the field of nanomaterials, can solve problems such as low specific capacity and limited energy density of lithium-ion batteries, achieve low production costs, improve cycle stability and rate performance, and have good dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A nanocomposite material of molybdenum trioxide@molybdenum disulfide core-shell heterostructure, comprising the following steps:

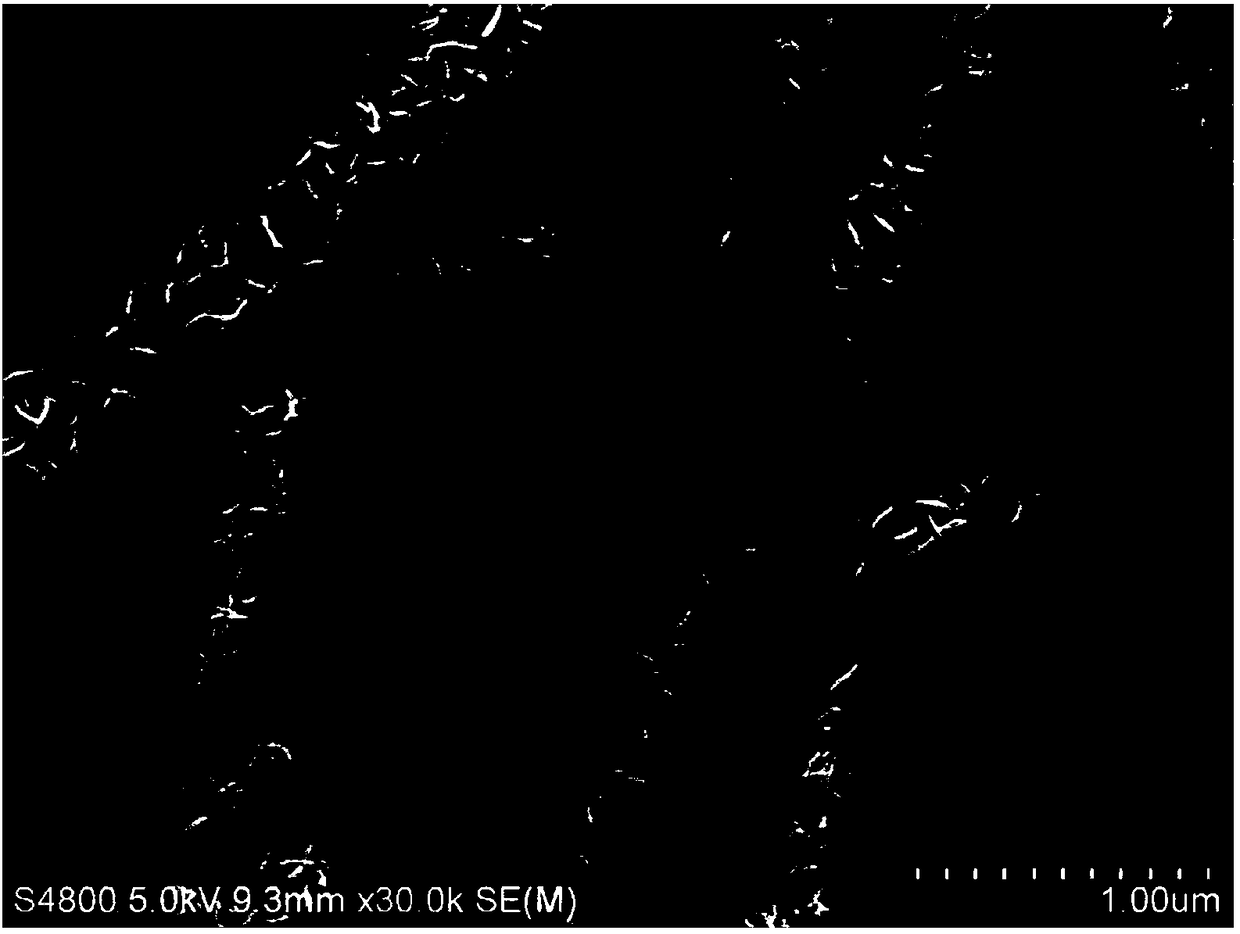

[0039] S1: Dissolve sodium molybdate in twice-distilled water and add hydrochloric acid with a mass concentration of 36%, stir for 30 minutes, and mix well to obtain a mixed solution. The concentration of sodium molybdate in the mixed solution is 0.2M, and the concentration of HCl is 0.4M; Transfer the solution to a 100mL stainless steel polytetrafluoroethylene high-temperature reaction kettle, and conduct a hydrothermal reaction at 180°C for 12 hours. Take out the reaction kettle and cool it to room temperature naturally. After that, the product is collected by centrifugation, and then washed with water and absolute ethanol for 3-5 times , and then put the product into a vacuum drying oven at 60°C for 12 hours to obtain a nanoribbon-shaped molybdenum trioxide precursor. The SEM image is as follows figure 1 As shown, it can be seen from the ...

Embodiment 2

[0045] A method for preparing a nanocomposite material of molybdenum trioxide@molybdenum disulfide core-shell heterostructure, comprising the following steps:

[0046] S1: Dissolve sodium molybdate in double distilled water and add hydrochloric acid with a mass concentration of 36%, stir for 30 minutes, and after mixing, a mixed solution is obtained. The concentration of sodium molybdate in the mixed solution is 0.2M, and the concentration of HCl is 0.4M; Transfer the mixed solution to a 100mL stainless steel polytetrafluoroethylene high-temperature reaction kettle, and conduct a hydrothermal reaction at 180°C for 12 hours. Take out the reaction kettle and cool it down to room temperature naturally. After that, the product is collected by centrifugation, and then washed with water and absolute ethanol for 3-5 times respectively. , and then put the product into a vacuum drying oven at 60° C. for 12 hours to obtain a nanoribbon-shaped molybdenum trioxide precursor.

[0047] S2: ...

Embodiment 3

[0049] A method for preparing a nanocomposite material of molybdenum trioxide@molybdenum disulfide core-shell heterostructure, comprising the following steps:

[0050] S1: Dissolve sodium molybdate in twice-distilled water and add hydrochloric acid with a mass concentration of 36%, stir for 30 minutes, and mix well to obtain a mixed solution. The concentration of sodium molybdate in the mixed solution is 0.2M, and the concentration of HCl is 0.4M; The solution was transferred to a 100mL stainless steel polytetrafluoroethylene high-temperature reaction kettle, and reacted hydrothermally at 180°C for 12 hours. The reaction kettle was taken out and cooled to room temperature naturally. After that, the product was collected by centrifugation, and then washed with water and absolute ethanol for 3-5 times respectively. Then put the product into a vacuum drying oven at 60°C and dry for 12 hours to obtain a nanoribbon-shaped molybdenum trioxide precursor.

[0051] S2: Add the nanoribb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com