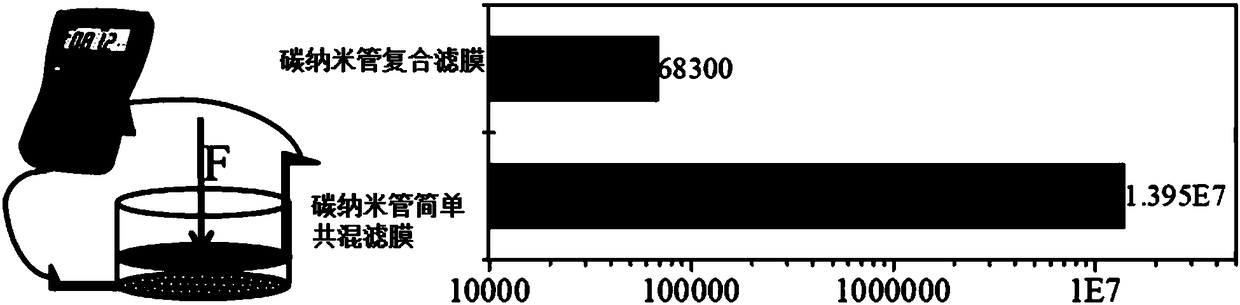

High-throughput composite filter membrane based on inner hole property of carbon nanotubes and preparation method

A carbon nanotube and high-throughput technology, applied in the field of materials, can solve the problems of inability to prepare filter membranes, difficulty in large-scale synthesis, and high cost, and achieve the effects of fast fluid transportation, excellent electrical conductivity, and reduced resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

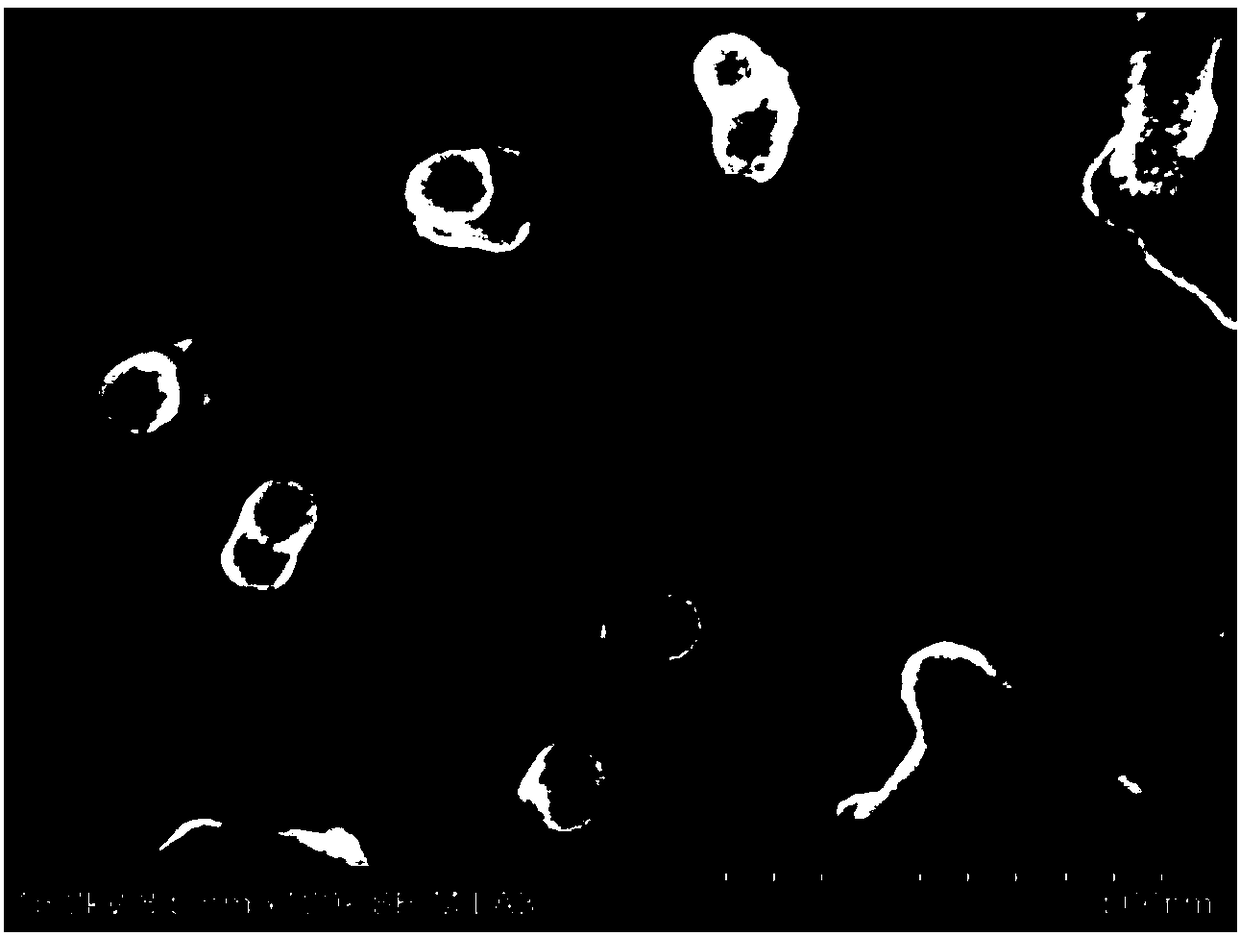

[0050] The preparation method of the carbon nanotube high flux composite filter membrane of the present embodiment comprises the following steps:

[0051] 1) Purification of carbon nanotubes: put 500mg of carbon nanotubes in a three-necked flask, add 250mL of concentrated hydrochloric acid, heat and stir in a constant temperature oil bath at 70°C for 12h, filter and wash with water until neutral, and dry at 80°C for later use; Among them, the carbon nanotubes have a length of 50 μm and an outer diameter of 10 nm.

[0052] 2) Preparation of polymer solution: Add 20 mL of azide dimethylacetamide and 0.6 g of polyethersulfone into a 100 mL beaker, and stir at 70° C. for 24 hours.

[0053] 3) Preparation of carbon nanotube-polymer dispersion: Take 3 mg of purified carbon nanotubes in step 1) and add them to the polymer solution in step 2) to prepare a carbon nanotube-polymer dispersion, ultrasonically disperse for 15 minutes, and ultrasonically 40 s , stop for 20s. In the disper...

Embodiment 2

[0064] The preparation method of the carbon nanotube high flux composite filter membrane of the present embodiment comprises the following steps:

[0065] 1) Purification of carbon nanotubes: put 500mg of carbon nanotubes in a three-necked flask, add 250mL of concentrated hydrochloric acid, heat and stir in a constant temperature oil bath at 60°C for 12h, filter and wash with water until neutral, and dry at 80°C for later use; Among them, the carbon nanotubes have a length of 100 μm and an outer diameter of 30 nm.

[0066] 2) Preparation of the polymer solution: Add 20 mL of nitrogen dimethylacetamide and 0.6 g of polyvinylidene fluoride into a 100 mL beaker, and stir at a constant temperature of 70° C. for 24 hours.

[0067] 3) Preparation of carbon nanotube-polymer dispersion: Take 4.8 mg of purified carbon nanotubes in step 1) and add them to the polymer solution in step 2) to prepare a carbon nanotube-polymer dispersion, ultrasonically disperse for 12 minutes, and 40s, st...

Embodiment 3

[0072] The preparation method of the carbon nanotube high flux composite filter membrane of the present embodiment comprises the following steps:

[0073] 1) Purification of carbon nanotubes: put 500 mg of carbon nanotubes in a three-necked flask, add 250 mL of concentrated hydrochloric acid, heat and stir in an oil bath at 80°C for 12 hours, filter and wash with water until neutral, and dry at 80°C for later use; Among them, the carbon nanotubes have a length of 80 μm and an outer diameter of 20 nm.

[0074]2) Preparation of polymer solution: Add 20 mL of azide dimethylacetamide and 0.6 g of polyethersulfone into a 100 mL beaker, and stir at 70° C. for 24 hours.

[0075] 3) Preparation of carbon nanotube-polymer dispersion: Take 2.4 mg of purified carbon nanotubes in step 1) and add them to the polymer solution in step 2) to prepare a carbon nanotube-polymer dispersion, ultrasonically disperse for 10 min, and 40s, stop for 20s. In the dispersion liquid, the carbon nanotube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com