A spray drying process for preparing yag ceramic powder

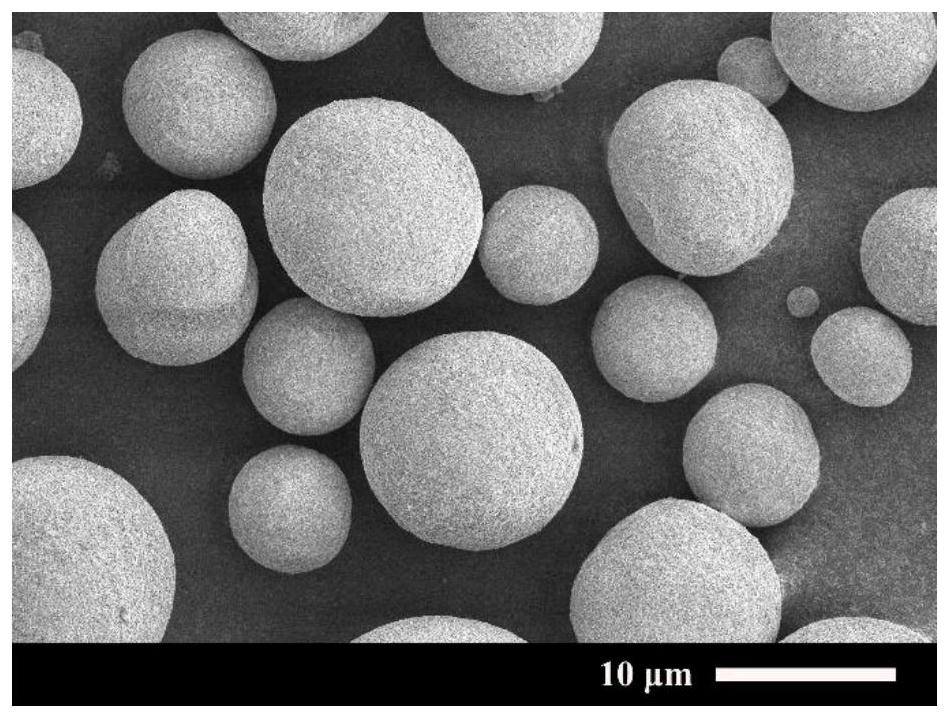

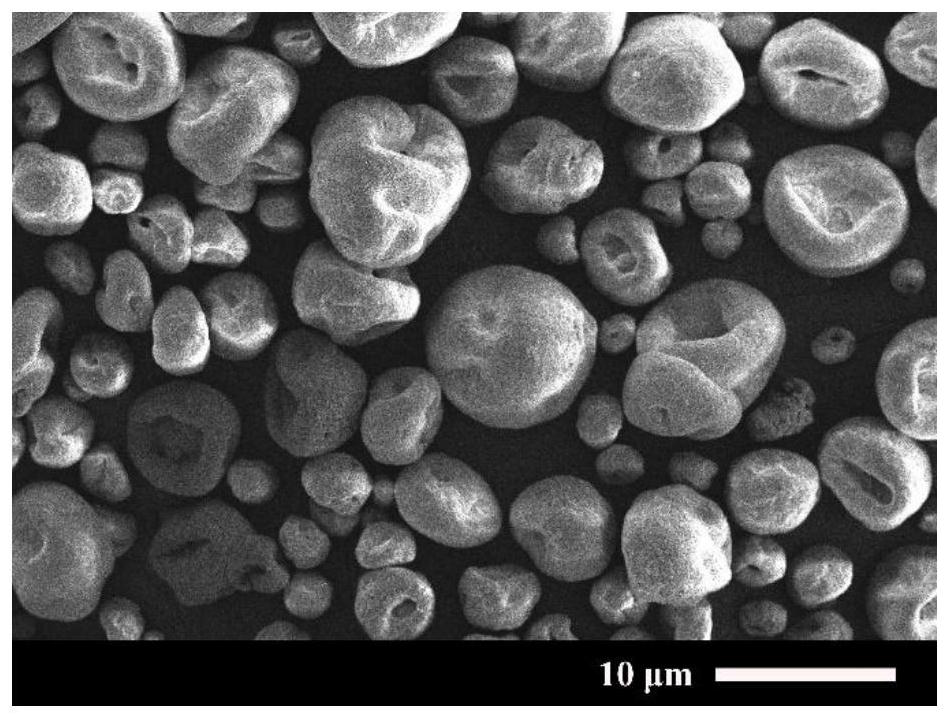

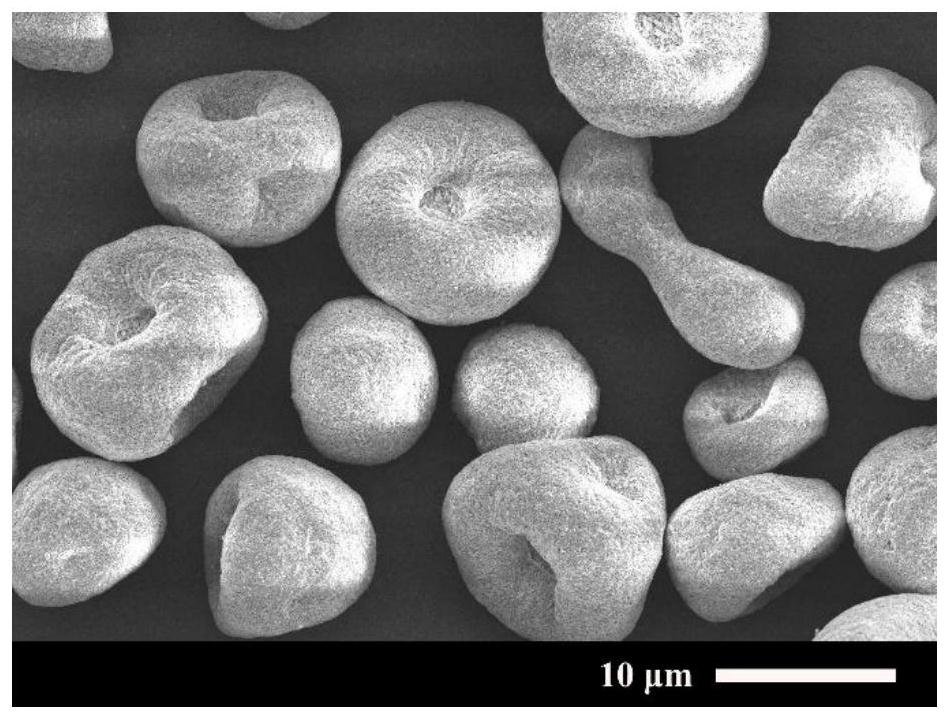

A drying process and technology of ceramic powder, applied in the field of ceramic processing, can solve the problems of low purity of YAG ceramic particles and complicated process, and achieve the effect of shortening preparation time, simplifying process flow and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The spray drying process that the present invention is used to prepare YAG ceramic powder specifically comprises the following steps:

[0028] S1. Raw material selection: choose alumina hydrosol, the average diameter of solid phase particles is about 60nm, and the solid content is 20wt%; choose yttrium oxide hydrosol, the average diameter of solid phase particles is about 75nm, and the solid content is 25wt%.

[0029] S2. Weighing: Weigh the two raw materials respectively to ensure that their molar ratio is 3:5, so as to determine that Y 3 al 5 o 12 garnet phase.

[0030] S3. Mix and configure the slurry: After mixing the two colloidal raw materials into a slurry, stir for 45 minutes, then use a small amount of ammonia water and nitric acid to adjust the pH to neutral, about 7.2, and then add deionized water to properly dilute to a solid content of 12wt %, adjust and confirm the pH again.

[0031] S4. Spray drying: The slurry is spray-dried, and the drying parameter...

Embodiment 2

[0034] S1. Raw material selection: choose alumina hydrosol, the average diameter of solid phase particles is about 50nm, and the solid content is 30wt%; choose yttrium oxide hydrosol, the average diameter of solid phase particles is about 60nm, and the solid content is 30wt%.

[0035] S2. Weighing: Weigh the two raw materials respectively to ensure that their molar ratio is 3:5, so as to determine that Y 3 al 5 o 12 garnet phase.

[0036] S3. Mixing and preparing slurry: After mixing the two colloidal raw materials into a slurry, stir for 60 minutes, then use a small amount of ammonia water and nitric acid to adjust the pH to neutral, about 6.8, and then add deionized water to properly dilute to a solid content of 15wt %, adjust and confirm the pH again.

[0037] S4. Spray drying: The slurry is spray-dried, and the drying parameters are: nozzle diameter 1.0mm, air inlet temperature at the nozzle 200°C, air volume 40m3 / h, and liquid supply volume 10ml / min.

[0038] S5. Calc...

Embodiment 3

[0040] S1. Raw material selection: choose alumina hydrosol, the average diameter of solid phase particles is about 90nm, and the solid content is 15wt%; choose yttrium oxide hydrosol, the average diameter of solid phase particles is about 110nm, and the solid content is 15wt%.

[0041] S2. Weighing: Weigh the two raw materials respectively to ensure that their molar ratio is 3:5, so as to determine that Y 3 al 5 o 12 garnet phase.

[0042] S3. Mix and configure the slurry: After mixing the two colloidal raw materials into a slurry, stir for 20 minutes, then use a small amount of ammonia water and nitric acid to adjust the pH to neutral, about 7.5, and then add deionized water to properly dilute to a solid content of 10wt %, adjust and confirm the pH again.

[0043] S4. Spray drying: The slurry is spray-dried. The drying parameters are: nozzle diameter 0.5mm, air inlet temperature at the nozzle 180°C, air volume 25m3 / h, and liquid supply volume 20ml / min.

[0044] S5. Calcinat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com