High-purity sodium ethylenediamine ethyl sulfonate synthesis method

A technology of sodium ethylenediaminoethanesulfonate and sodium vinylsulfonate, which is applied in the preparation of sulfonic acid, sulfonate salt, chemical instruments and methods, etc., can solve the complex process and the price of sodium chloroethylsulfonate. Expensive and other problems, to achieve the effect of simple process, cheap raw materials and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

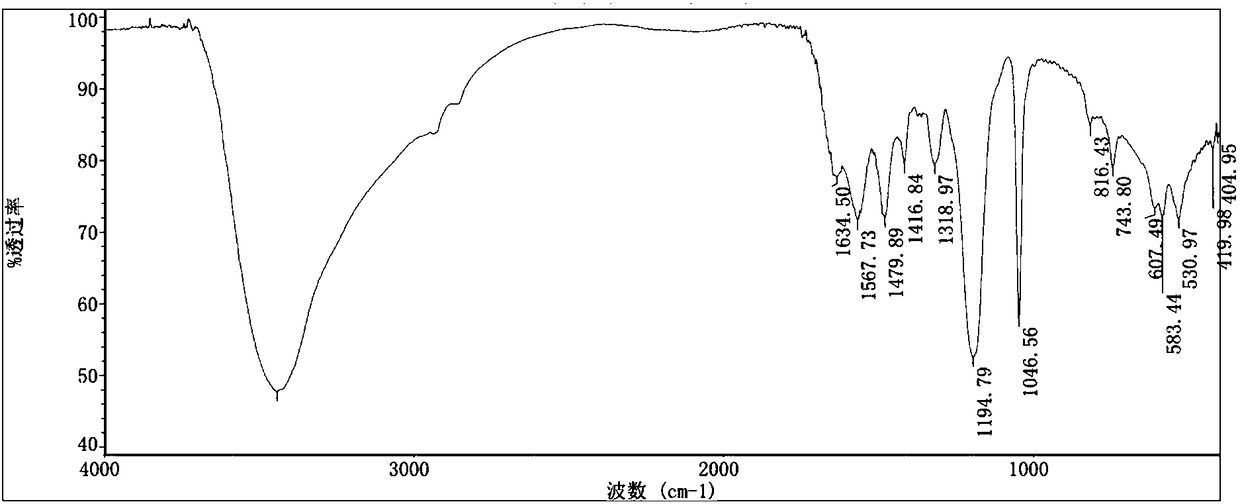

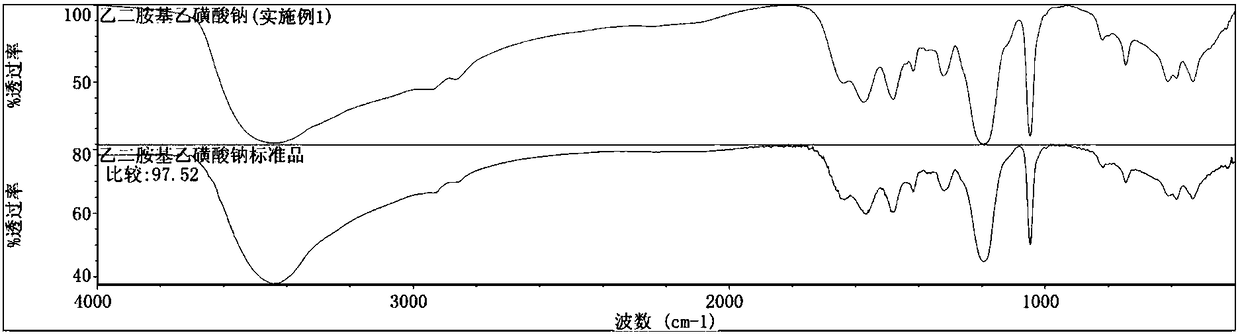

Image

Examples

Embodiment 1

[0024] 1. At 30°C, add 60g (1mol) ethylenediamine to a 1000ml reaction flask, then slowly add 25wt% sodium vinyl sulfonate solution dropwise to the reaction flask while stirring, and complete the dropwise addition within 1 hour, then Heat up to reflux while stirring, reflux for 4 hours, cool down to 30°C to obtain a mixed solution containing sodium ethylenediaminoethanesulfonate;

[0025] 2. Pass the mixed solution through D001 type sulfonic acid resin adsorption column, absorb unreacted ethylenediamine and sodium ethylenediaminoethanesulfonate, and elute with deionized water to remove polyvinylsulfonic acid, hydroxyethyl Acidic impurities such as sulfonic acid, sulfate group and unreacted sodium vinyl sulfonate stop eluting when the pH value is greater than 6;

[0026] 3. Elute with 10wt% sodium hydroxide solution to replace the adsorbed ethylenediamine and ethylenediaminoethanesulfonic acid. When the pH value is greater than 12, stop the elution and collect the Adsorb the l...

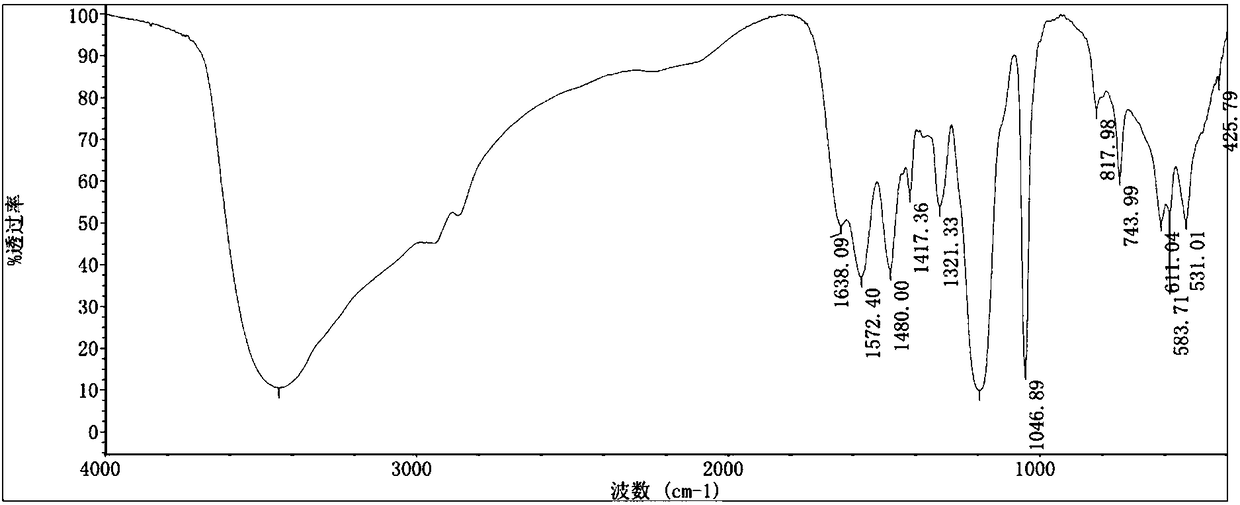

Embodiment 2

[0033] The quality that ethylenediamine is added becomes 90g, and other operations and steps are identical with embodiment 1, finally obtains 370g product, and sampling measures solid content 50.5%, content is 50.3%, nitrogen content 7.370 (theoretical value 7.368), conversion The resulting purity is 99.97%, and the yield is 97.37%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com