Preparation method of ferrocene-based azo-phenyl amphiphilic segmented copolymer material for preparing regular honeycomb membrane

A ferrocene-based azophenyl group and amphiphilic block technology, which is applied in the field of amphiphilic block copolymer material preparation, can solve the problems of irregular pore arrangement and limited pore shape, and achieve good thermal stability , the ratio is flexible and adjustable, and the stimulus response phenomenon is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

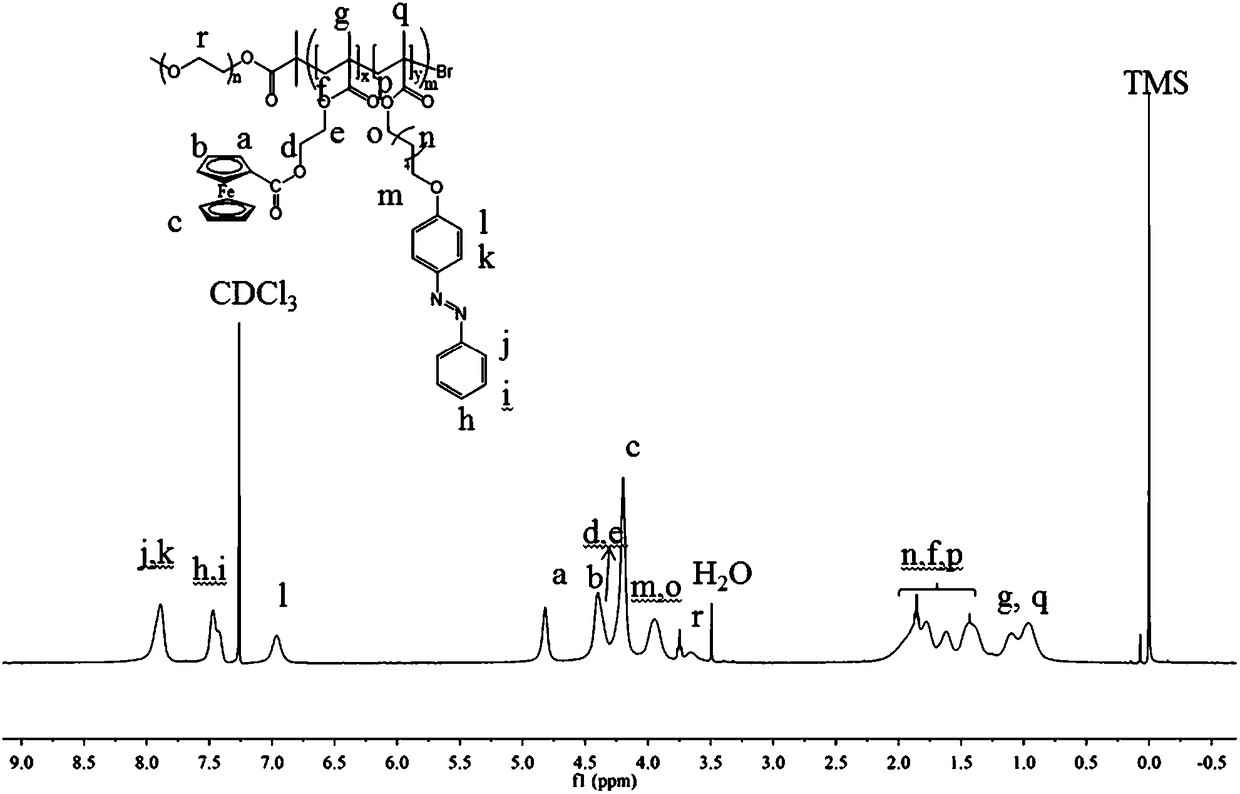

Embodiment 1

[0043] ① Under anhydrous and oxygen-free conditions, dissolve 9.4195g (40.9mmol) of ferrocenecarboxylic acid in reflux-dried 100mL of dichloromethane solvent, add 3.2mL of pyridine as catalyst, and 5.0mL of oxalyl chloride (58.6mmol) as Acyl chloride reagent, reflux reaction for 5 hours, remove the solvent and excess oxalyl chloride in a vacuum, add 100mL of petroleum ether (60-90°C), reflux for 2 hours, filter under reduced pressure, and remove the petroleum ether in a vacuum to obtain ferrocenecarbonyl chloride;

[0044]②Add reflux-dried 80mL tetrahydrofuran to 8.7020g (35.0mmol) ferrocenecarbonyl chloride as a solvent, 4.0mL triethylamine as a catalyst, slowly add 4.0mL (35.4mmol) hydroxyethyl methacrylate dropwise, and reflux for 5h , filtered under reduced pressure, the filtrate was rotary evaporated, and the solvent was removed to obtain the crude product of ferroceneformyloxyethyl methacrylate, which was successively washed with 250mL saturated Na 2 CO 3 The solution a...

Embodiment 2

[0053] Front four steps are as embodiment 1, and back two steps are as follows:

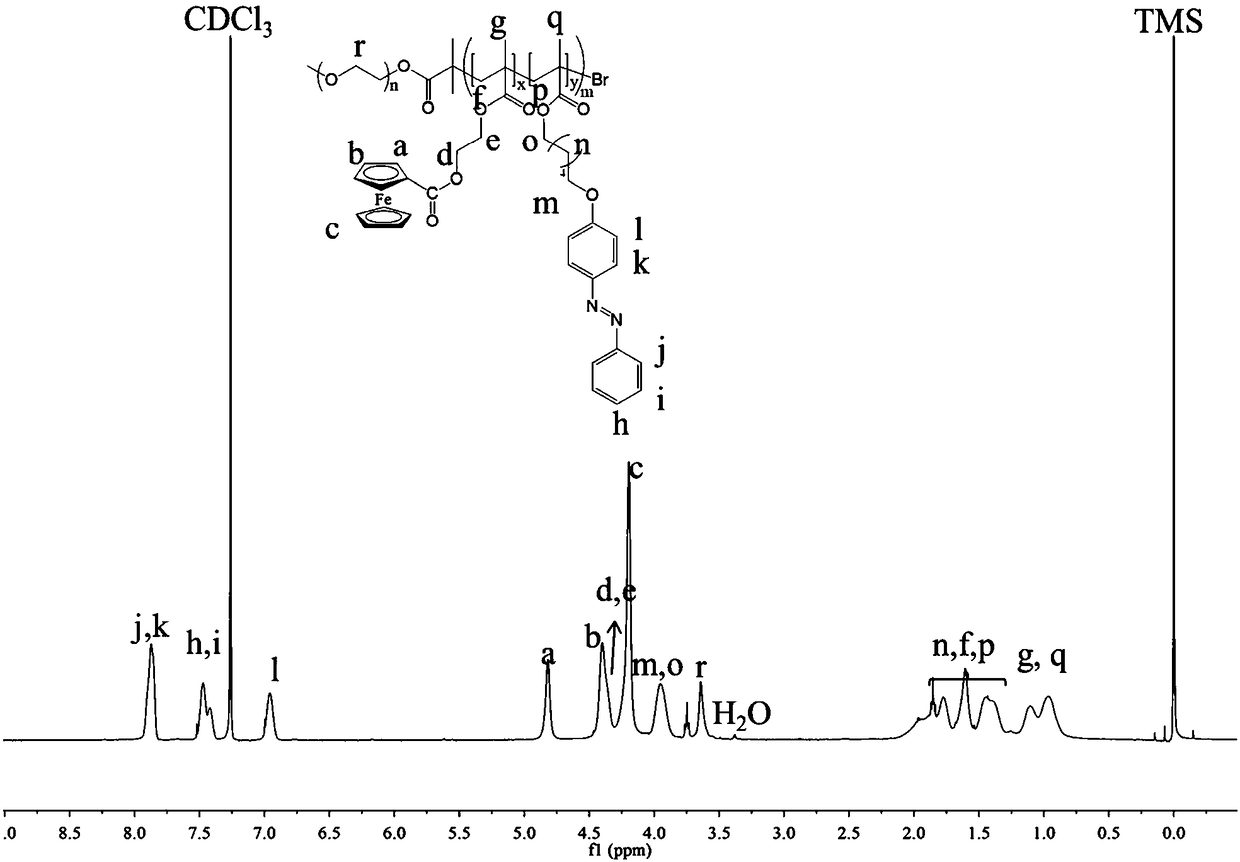

[0054] ⑤ Weigh 2.0590 g (2 mmol) of polyethylene glycol monomethyl ether with a molecular weight of 1000, and vacuumize to remove water and dry for 0.5 h. Under the protection of argon, add 40mL of reflux-dried THF to dissolve, add 0.6mL (4mmol) triethylamine, slowly add 0.5mL (4mmol) 2-bromoisobutyryl bromide dropwise under ice-water bath, and react at 25°C 10h. After the reaction was completed, filter under reduced pressure, concentrate the filtrate by rotary evaporation, add dropwise to 250 mL of n-hexane for precipitation, and extract the precipitate by suction filtration. The precipitate was dissolved in 2 mL of THF, then precipitated with 250 mL of n-hexane and filtered, and the operation was repeated three times. The obtained precipitate was dried in a vacuum oven at 20°C for 24 hours to obtain the product.

[0055] ⑥Add 114.0mg of PEO-Br, 1.7275g of FcEMA, and 1.8345g of MAAZOOHEE in tu...

Embodiment 3

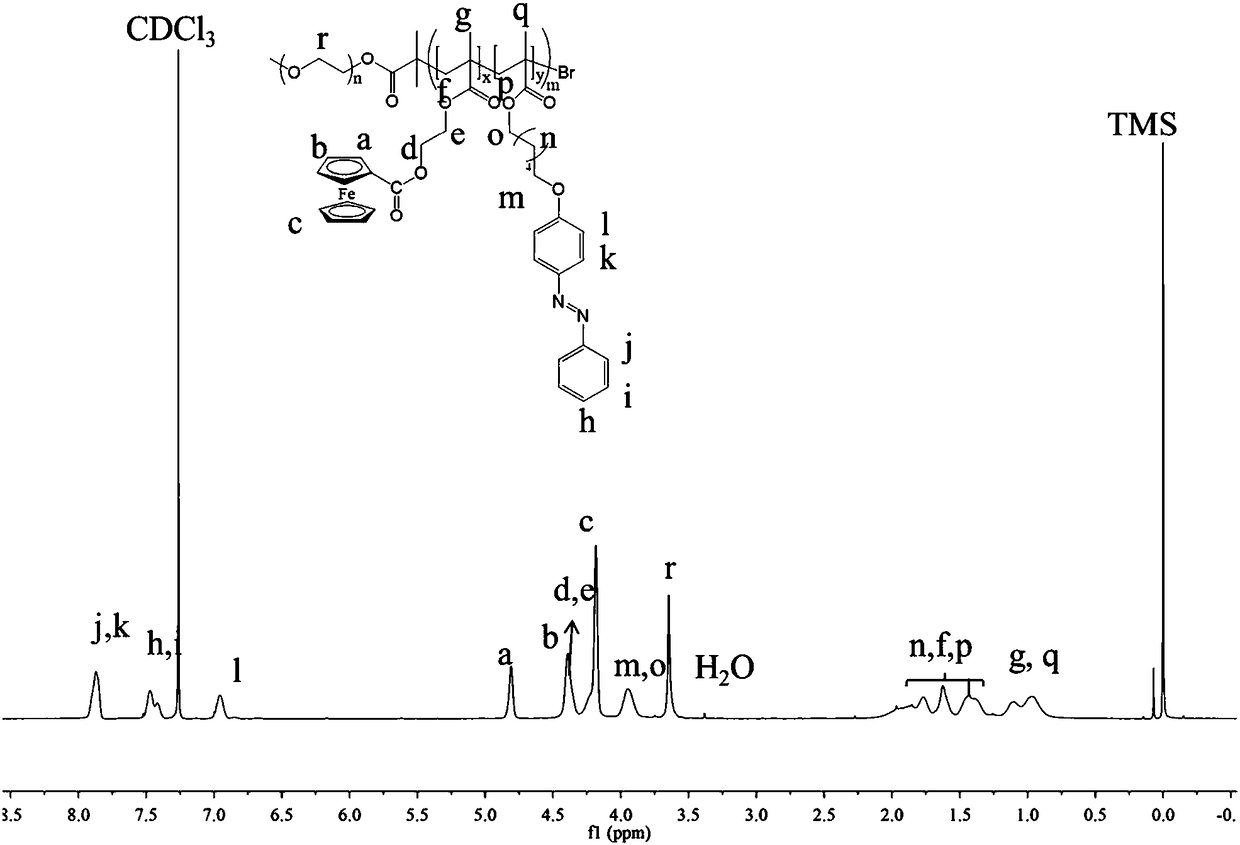

[0059] Front four steps are as embodiment 1, and back two steps are as follows:

[0060] ⑤ Weigh 4.0183 g (2 mmol) of polyethylene glycol monomethyl ether with a molecular weight of 2000, and vacuumize to remove water and dry for 0.5 h. Under the protection of argon, add 40mL of reflux-dried THF to dissolve, add 0.6mL (4mmol) triethylamine, slowly add 0.5mL (4mmol) 2-bromoisobutyryl bromide dropwise under ice-water bath, and react at 25°C 10h. After the reaction was completed, filter under reduced pressure, concentrate the filtrate by rotary evaporation, add dropwise to 250 mL of n-hexane for precipitation, and extract the precipitate by suction filtration. The precipitate was dissolved in 2 mL of THF, then precipitated with 250 mL of n-hexane and filtered, and the operation was repeated three times. The obtained precipitate was dried in a vacuum oven at 20°C for 24 hours to obtain the product.

[0061] ⑥Add 214.6mg of PEO-Br, 1.7066g of FcEMA, and 1.8250g of MAAZOOHEE in tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com