Ultra-hard waterproof, anti-fouling and wear-resistant coating film, plating process and detecting method of ultra-hard waterproof, anti-fouling and wear-resistant coating film

A detection method and anti-fouling technology, applied in the direction of testing wear resistance, metal material coating technology, sputtering plating, etc., can solve the problems of inability to meet the appearance and durability of plated parts, complex surface properties of ceramic materials, etc. To achieve the effect of improving waterproof and anti-fingerprint performance, good gloss and wear and corrosion resistance, improved hand feel and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

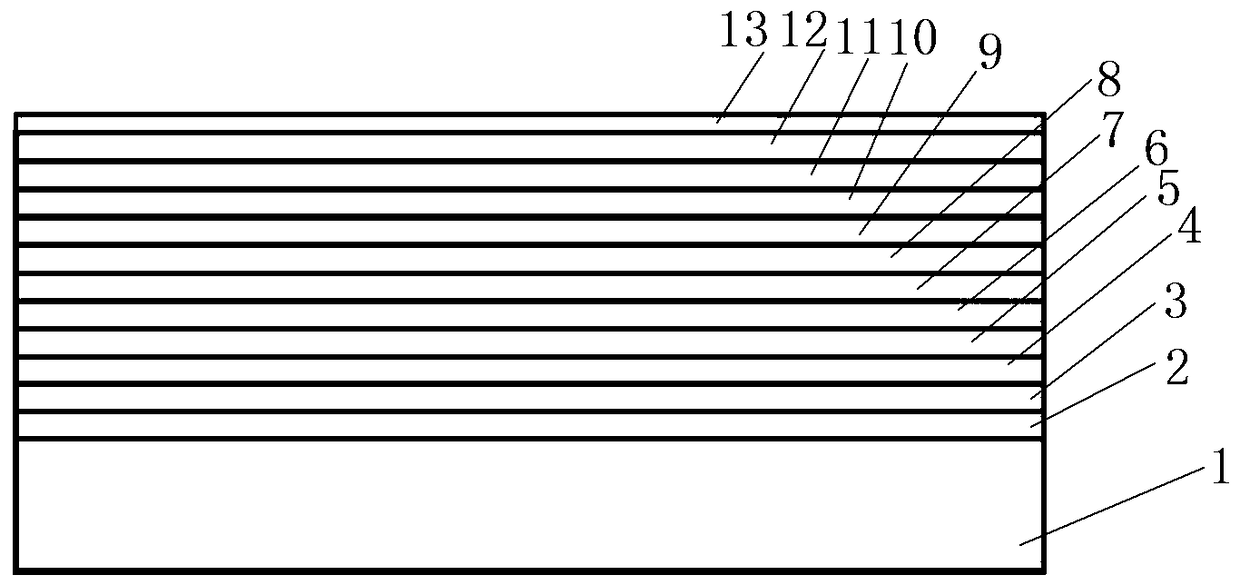

[0029] Embodiment 1: The coating has 11 layers of film, and the color film layer is champagne gold, made of SiO 2 and Si 3 N x (x=3~5) The film layers are arranged in a staggered manner, and the optimized film system design formula is used

[0030] A / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / B / C, wherein A is ceramics, as the base layer 1, the first film layer 2 to the eleventh film layer 12 are respectively

[0031] SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 , B is a fluoropolymer (10~20nm), used as the antifouling layer 13, C is an air medium with a refractive index NA=1, the reference wavelength λc=550nm, and listed in order, the physical thickness of each film layer is A / 150~200nm / 20~70nm / 20~60nm / 10~40nm / 20~60nm / 10~50nm / 10~40nm / 10~30nm / 30~70nm / 20~70nm / 10~30nm / 10...

Embodiment 2

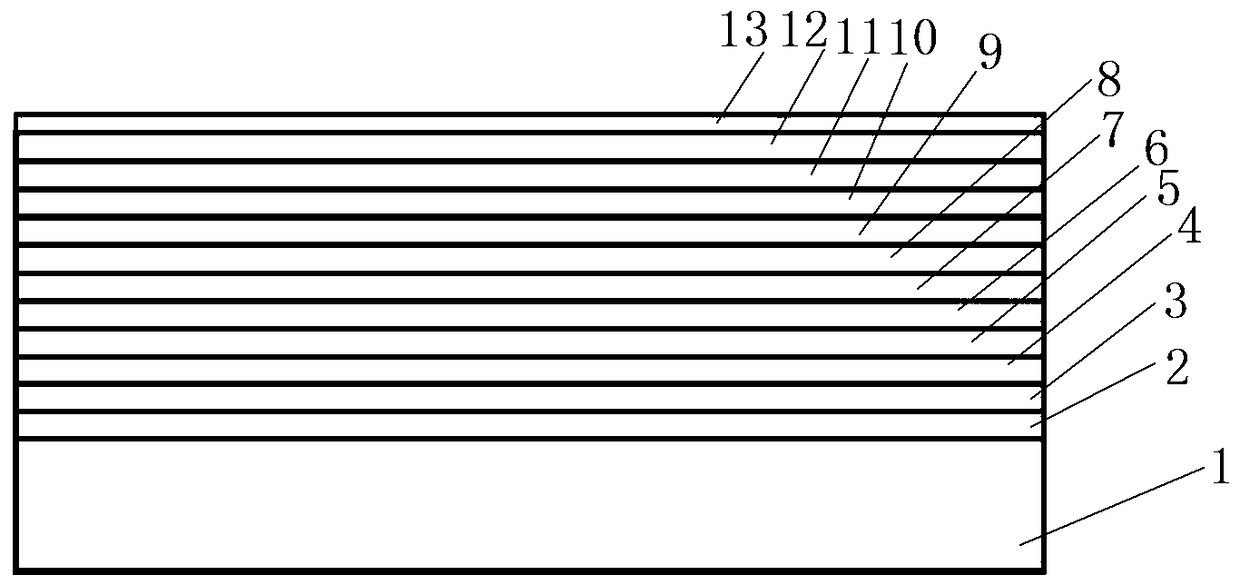

[0032] Embodiment 2: The coating has 11 layers of film, and the color film layer is silver, made of SiO 2 and Si 3 N x (x=3~5) The film layers are arranged in a staggered manner, and the optimized film system design formula is used

[0033] A / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x(x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / B / C, A is ceramic, as the base layer 1, the first film layer 2 to the eleventh film layer 12 are respectively

[0034] SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 , B is a fluoropolymer (10~20nm), used as the antifouling layer 13, C is an air medium with a refractive index NA=1, the reference wavelength λc=550nm, and listed in order, the physical thickness of each film layer is A / 10~20nm / 20~50nm / 10~30nm / 10~40nm / 10~40nm / 50~150nm / 100~200nm / 50~150nm / 30~60nm / 40~80nm / 10 ~30 nm / 10~20 nm / C, use ...

Embodiment 3

[0035] Embodiment 3: The coating has 7 layers of film, and the color film layer is bright blue, made of SiO 2 and Si 3 N x (x=3~5) The film layer is arranged in a staggered manner, using the optimized film system design formula A / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / B / C, A is ceramic, as the base layer 1, the first film layer 2 to the seventh film layer 8 are respectively

[0036] SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 / Si 3 N x (x=3~5) / SiO 2 , B is a fluoropolymer (10~20nm), used as the antifouling layer 13, C is an air medium with a refractive index NA=1, the reference wavelength λc=550nm, and listed in order, the physical thickness of each film layer is in order

[0037] A / 10~40nm / 50~100nm / 120~200nm / 10~50nm / 10~40nm / 10~30nm / 100~200nm / 10~20nm / C, use a sputtering coating machine to compile the film system according to the order and thickness of the formula list , and then use ceramics as the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drop angle | aaaaa | aaaaa |

| Surface contact angle | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com