Method of separating and purifying various antigen ingredients of pertussis

A separation, purification and pertussis technology, which is applied in the field of biomedicine, can solve the problems of destroying the immunogenicity of FHA, loss of PT and FHA, and difficult removal of PT, and achieves the effects of good immunogenicity, good integrity and improved recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1, fermentation culture of Bacillus pertussis

[0063] experiment material:

[0064] Strains: pertussis phase I CS strain, CMCC58003. Sourced from China National Institutes for Food and Drug Control. Pertussis phase I CS strain, CMCC58003. Sourced from China National Institutes for Food and Drug Control.

[0065] Medium: acellular pertussis SSM complete comprehensive medium

[0066] Main equipment: Bioengineering AG fully automatic fermentation system (50L, 500L, 5000L)

[0067] experiment method:

[0068] The working seed batch of pertussis bacillus was opened, inoculated on Jiang's medium containing 15% sheep blood modified bag, cultured at 35°C for 72 hours, then transferred to activated carbon semi-comprehensive medium, and cultivated at 37°C for 48 hours; Generation 3 (activated charcoal semi-comprehensive medium), continue culturing at 37°C for 48 hours, then scrape seeds in 250ml phosphate buffer (i.e. PBS buffer, 137mM NaCl, 2.7mM KCl, 10mM NaCl...

Embodiment 2

[0071] Embodiment 2, the centrifugation of large tank fermented liquid

[0072] Experimental materials and samples: pertussis bacteria liquid 3500L

[0073] Main equipment: disc centrifuge, Alfa Laval CLARA 250

[0074] experiment method:

[0075] Centrifuge 500 liters of pertussis fermentation and harvested bacteria liquid with a disc centrifuge. The centrifuge feed flow rate is 1000-1500L / h, and the slag discharge time is 5-10min. By reducing the feed flow rate and shortening the slag discharge time, the centrifuge The turbidity of the supernatant of the bacterial liquid was ≤30NTU, and the bacterial precipitate was collected.

[0076] test results:

[0077] Harvest 475 liters of bacterial supernatant, with a turbidity value of 11.4 NTU.

Embodiment 3

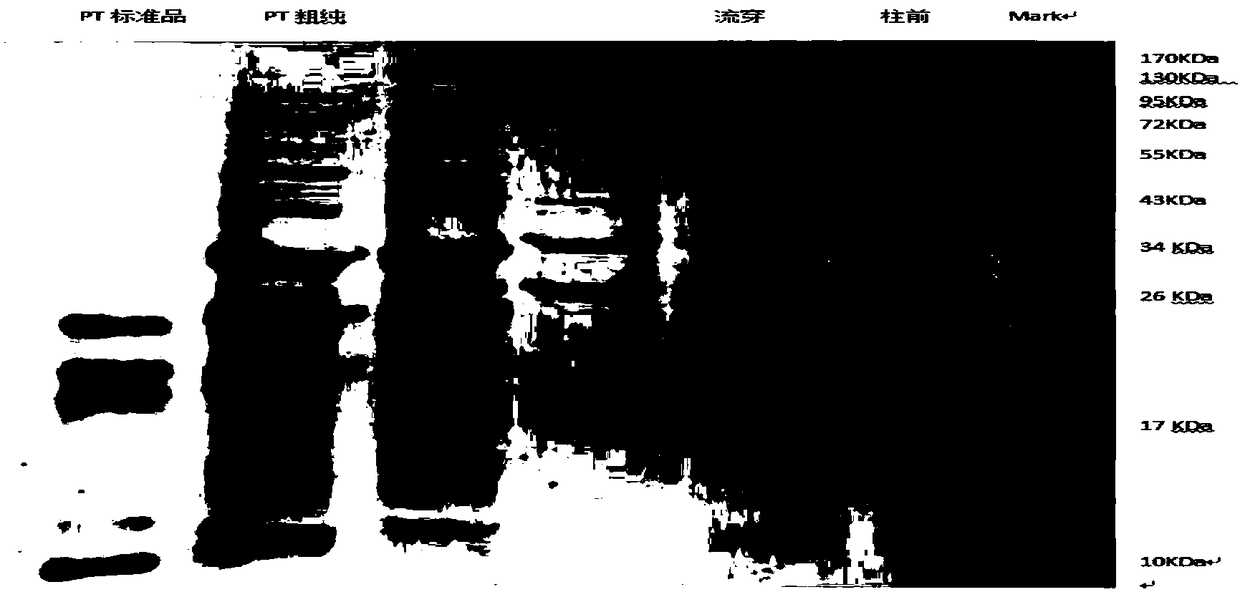

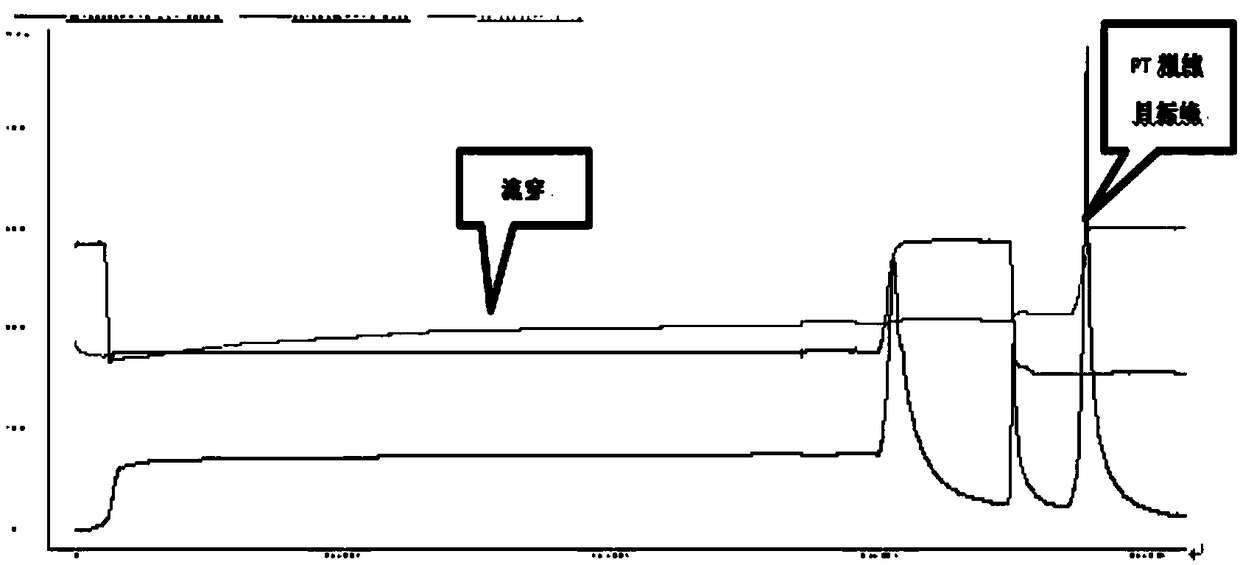

[0078] Example 3, Separation and Purification of PT Antigen from Fermentation Broth Supernatant

[0079] 1. Ultrafiltration treatment of fermentation broth

[0080] Test materials and samples:

[0081] Ultrafiltration membrane pack: Pellicon2 Biomax 30, Milipore

[0082] Tangential flow treatment system: CUF200SA membrane package ultrafiltration system, Milipore

[0083] Sample: Bacterial fluid harvested from pertussis fermentation, supernatant after centrifugation and separation of bacterial cells, the sample volume is 475 liters.

[0084] experiment method:

[0085] The supernatant after bacterial cell separation was concentrated by ultrafiltration using a polyethersulfone membrane bag with a molecular weight cut-off of 10KD / 30KD, and the pressure at the feed end during the concentration process was kept at 15psi-25psi. When the volume is concentrated to about 50 liters, use 3 to 5 times the volume replacement solution (10mM sodium citrate+2M urea+0.5MNaCl, pH=5.9-6.1) t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com