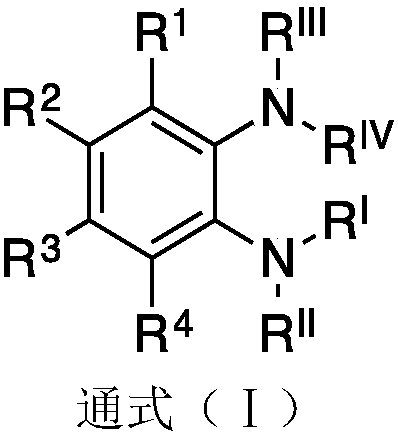

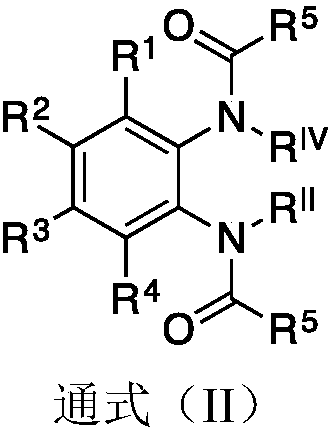

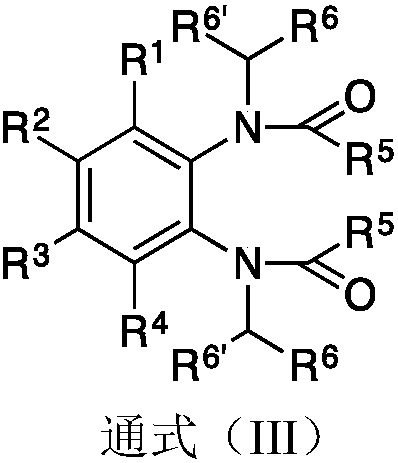

Solid catalyst component containing o-phenylenediamine compound, and catalyst and applications thereof

A technology of solid catalyst and o-phenylenediamine, applied in the field of combined solid catalyst group, can solve the problems of unfavorable development of PP, narrow relative molecular mass distribution and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0136] Preparation of solid catalyst components

[0137] The operations of preparing catalysts in the examples were all carried out under the protection of high-purity nitrogen. Specific examples are as follows.

Embodiment 1

[0139] In a 500ml stirred 5-neck flask fully replaced by nitrogen, add 10g of diethoxymagnesium and 80mL of toluene to prepare a suspension, and then add 20mL of titanium tetrachloride dropwise at -10°C. After the dropwise addition, the system After slowly raising the temperature to 10°C, add 60mL of titanium tetrachloride dropwise, then slowly raise the temperature to 90°C, add 3g of 1,2-di-n-hexanamide-phenylenediamine, then continue to raise the temperature to 120°C and keep the temperature for 2 hours, then press the liquid Filter it clean, remove the liquid, and wash the obtained solid three times with 120 mL of titanium tetrachloride at 125°C. The obtained solid was washed twice with 150 mL of hexane at 60°C and twice at room temperature, the liquid was filtered off and dried to obtain a solid powder which was the solid catalyst component. The titanium content, internal electron donor content and polymerization data of the solid catalyst components are shown in Table 4. ...

Embodiment 2-28

[0141] The preparation method of the solid catalyst component is the same as in Example 1, except that 1,2-di-n-hexanamide-phenylenediamine is replaced by the compounds in Table 1-Table 3 in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com