Starter feed for chickens after stopping heat preserving raising

A technology of open feed and temperature removal, which is applied in the field of poultry breeding feed, can solve the problems of poor foot diameter pigment deposition, high death rate of temperature removal chickens, and substandard body weight, etc., to improve intestinal health, increase survival rate and The uniformity of the flock and the effect of promoting synchronous development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The product is formulated according to the following weight percentages: 59% baked corn, 21% dehulled soybean meal, 3% expanded soybean, 2% cotton meal, 5% corn gluten meal, 4% corn DDGS, 0.6% soybean oil, 1.1% stone powder, hydrogen phosphate Calcium 1.59%, Sodium Chloride 0.3%, Lysine 0.6%, Methionine 0.15%, Threonine 0.1%, Choline Chloride 0.1%, Homizyme 0.01%, Citric Acid 0.3%, Montmorillonite 0.3%, Golden 0.12%, canthaxanthin 0.08%, baking soda 0.15%, multivitamin 0.3%, complex trace element 0.2%. Then weigh various raw materials according to a predetermined ratio; coarsely pulverize the dehulled soybean meal and cotton meal, and the pulverizer is equipped with a Φ2.0 sieve plate to control the pulverization particle size; then directly add to the horizontal double-shaft paddle mixer according to the ratio for mixing treatment ; Finally, the automatic baler completes the weighing.

[0025] Applications:

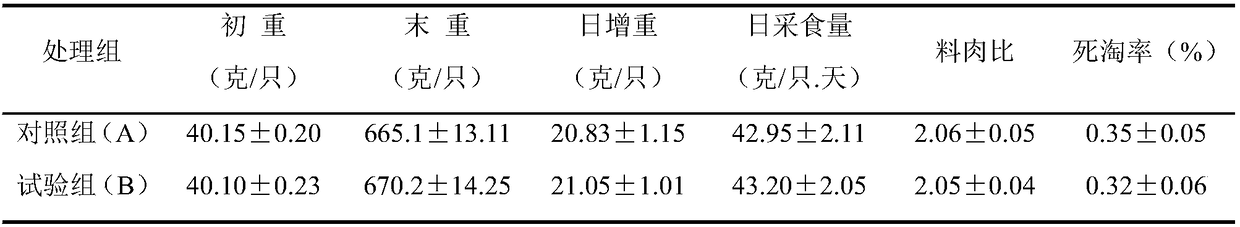

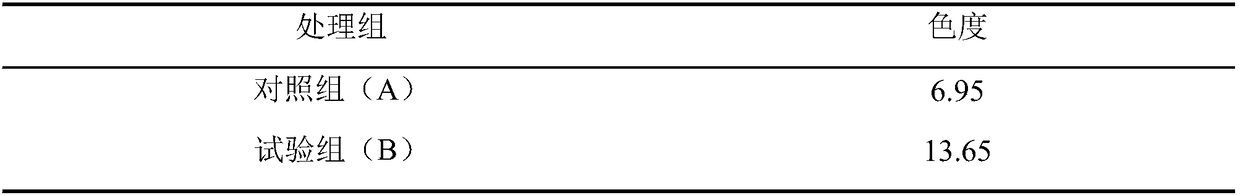

[0026] Location: Chengdu Xiangda University of Tangrenshen Grou...

Embodiment 2

[0036] The product is prepared according to the following weight percentages: baked corn 63%, dehulled soybean meal 23%, expanded soybean 1.5%, cotton meal 2%, corn gluten meal 3%, corn DDGS 2%, soybean oil 0.3%, stone powder 1.2%, hydrogen phosphate Calcium 1.6%, Sodium Chloride 0.3%, Lysine 0.39%, Methionine 0.1%, Threonine 0.05%, Choline Chloride 0.1%, Homizyme 0.01%, Citric Acid 0.3%, Montmorillonite 0.3%, Golden Vitamin 0.05%, Canthaxanthin 0.15%, Baking soda 0.15%, Multivitamin 0.3%, Complex trace element 0.2%. Then weigh various raw materials according to the predetermined ratio; coarsely pulverize the dehulled soybean meal and cotton meal, and the pulverizer is equipped with a Φ2.0 sieve plate to control the pulverization particle size; then directly add the horizontal double-shaft paddle mixer according to the ratio for mixing treatment ; Finally, the automatic baler completes the weighing.

[0037] Applications:

[0038] Location: Chengdu Xiangda University of Tangrensh...

Embodiment 3

[0048] The product is formulated according to the following weight percentages: 60% roasted corn, 22% dehulled soybean meal, 2.5% expanded soybean, 2% cotton meal, 4.5% corn gluten meal, 3.2% corn DDGS, 0.8% soybean oil, 0.94% stone powder, Calcium hydrogen phosphate 1.5%, sodium chloride 0.3%, lysine 0.5%, methionine 0.12%, threonine 0.08%, choline chloride 0.1%, Homizyme 0.01%, citric acid 0.3%, montmorillonite 0.3% , Golden pigment 0.1%, canthaxanthin 0.1%, baking soda 0.15%, multivitamin 0.3%, complex trace element 0.2%. Then weigh various raw materials according to the predetermined ratio; coarsely pulverize the dehulled soybean meal and cotton meal, and the pulverizer is equipped with a Φ2.0 sieve plate to control the pulverization particle size; then directly add the horizontal double-shaft paddle mixer according to the ratio for mixing treatment ; Finally, the automatic baler completes the weighing.

[0049] Applications:

[0050] Venue: Tangrenshen Group Co., Ltd. Chengd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fatty acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com