Preparation method of chlorin e6 and ferroferric oxide composite nanoparticle

A composite nanoparticle and ferric oxide technology, which is applied in nanotechnology, nanotechnology, nanomedicine, etc., can solve the problem of poor water solubility of photosensitizer chlorin e6, increase water solubility of photosensitizer chlorin e6, increase Problems such as blood circulation stability and dispersibility, to achieve the effect of increasing blood circulation stability and dispersibility, increasing water solubility, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

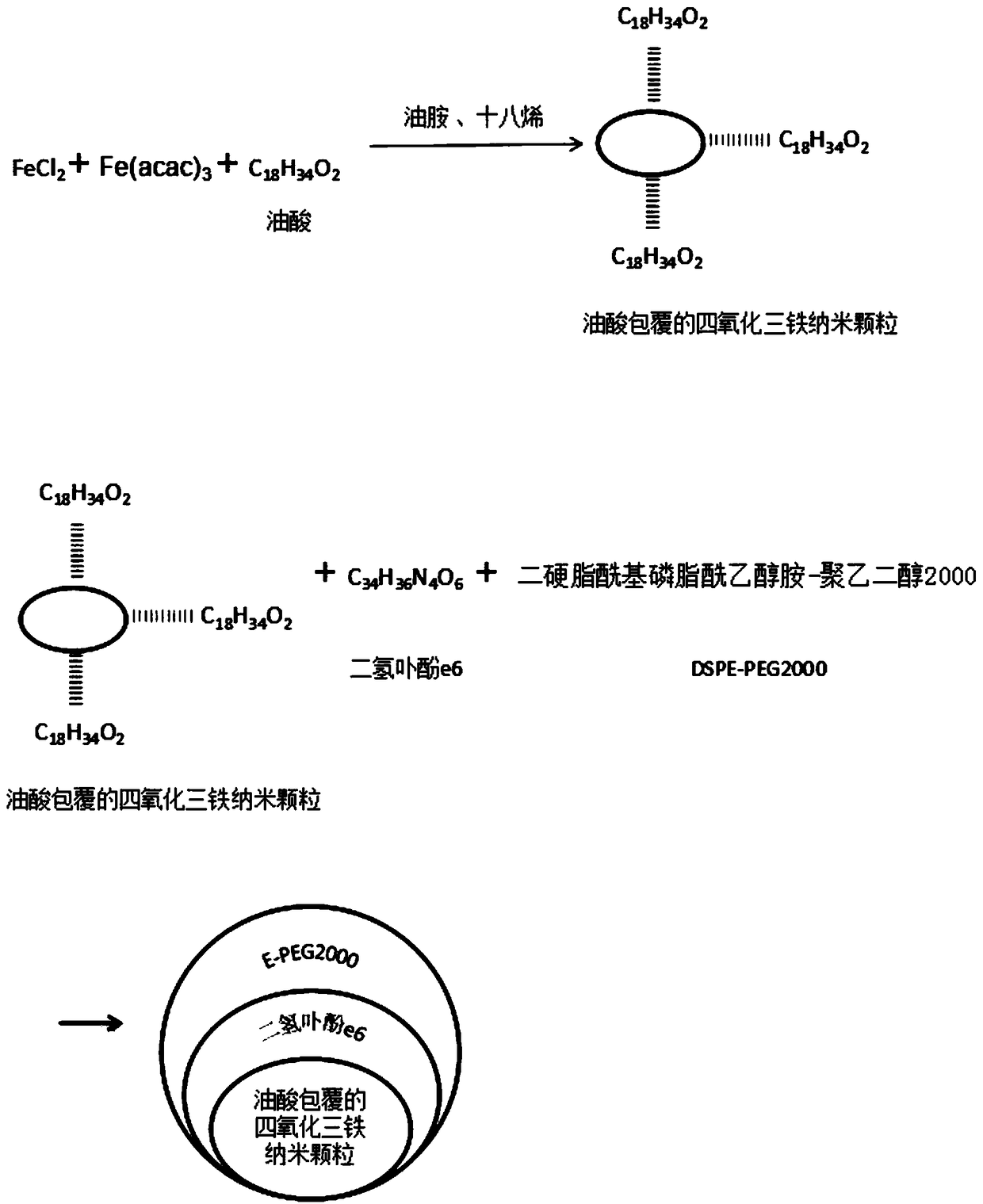

[0046] The preparation method of the chlorin e6 of the present embodiment and ferric oxide composite nanoparticle, comprises the steps:

[0047] Step 1: Preparation of oleic acid-coated Fe3O4 nanoparticles

[0048] Take 18mL of octadecene, add it to a 50mL three-necked bottle, blow in nitrogen, and then add 0.8mmol FeCl 2 Solution, 4mmol oleic acid and 4mmol oleylamine, heated to 100-120°C, stay for 1h; then add 1.8mmol Fe(acac) 3 solution, heated to 180°C, and stayed for 30 minutes; continued to heat to 280°C, stayed for 30 minutes, and then stopped the nitrogen to obtain crude ferric oxide nanoparticles coated with oleic acid;

[0049] Cool the crude iron ferric oxide nanoparticles coated with oleic acid to room temperature, add 50 mL of absolute ethanol for magnetic separation, then add 20 mL of acetone, centrifuge, take the precipitate, dissolve it in 20 mL of chloroform, and obtain pure Ferric oxide nanoparticles coated with oleic acid;

[0050] Step 2: Preparation of ...

Embodiment 2

[0053] Step 1: Preparation of oleic acid-coated Fe3O4 nanoparticles

[0054] Take 20mL of octadecene, add it to a 50mL three-necked bottle, blow in nitrogen, and then add 1.0mmol FeCl 2 Solution, 6mmol oleic acid and 6mmol oleylamine, heated to 100-120°C, stayed for 1h; then added 2.0mmol Fe(acac) 3 solution, heated to 200°C, and stayed for 30 minutes; continued heating to 290°C, and stayed for 30 minutes, then stopped the nitrogen gas to obtain crude ferric oxide nanoparticles coated with oleic acid;

[0055] Cool the crude iron ferric oxide nanoparticles coated with oleic acid to room temperature, add 75mL absolute ethanol, carry out magnetic separation, then add 35mL acetone, centrifuge, take the precipitate, dissolve it in 35mL chloroform, and obtain pure Ferric oxide nanoparticles coated with oleic acid;

[0056] Step 2: Preparation of composite nanoparticles of chlorin e6 and ferric oxide

[0057] Weigh 50 mg of distearoylphosphatidylethanolamine-polyethylene glycol 2...

Embodiment 3

[0059] Step 1: Preparation of oleic acid-coated Fe3O4 nanoparticles

[0060] Take 22mL of octadecene, add it to a 50mL three-neck bottle, blow in nitrogen, and then add 1.2mmol FeCl 2 solution, 7mmol oleic acid and 7mmol oleylamine, heated to 120°C and stayed for 1h; then added 2.2mmol Fe(acac) 3 solution, heated to 180-220°C, and stayed for 30 minutes; continued to heat to 300°C, and stayed for 30 minutes, then stopped the nitrogen gas to obtain crude ferric oxide nanoparticles coated with oleic acid;

[0061] Cool the crude iron ferric oxide nanoparticles coated with oleic acid to room temperature, add 100mL of absolute ethanol, perform magnetic separation, then add 50mL of acetone, centrifuge, take the precipitate, dissolve it in 50mL of chloroform, and obtain pure Ferric oxide nanoparticles coated with oleic acid;

[0062] Step 2: Preparation of composite nanoparticles of chlorin e6 and ferric oxide

[0063] Weigh 60 mg of distearoylphosphatidylethanolamine-polyethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

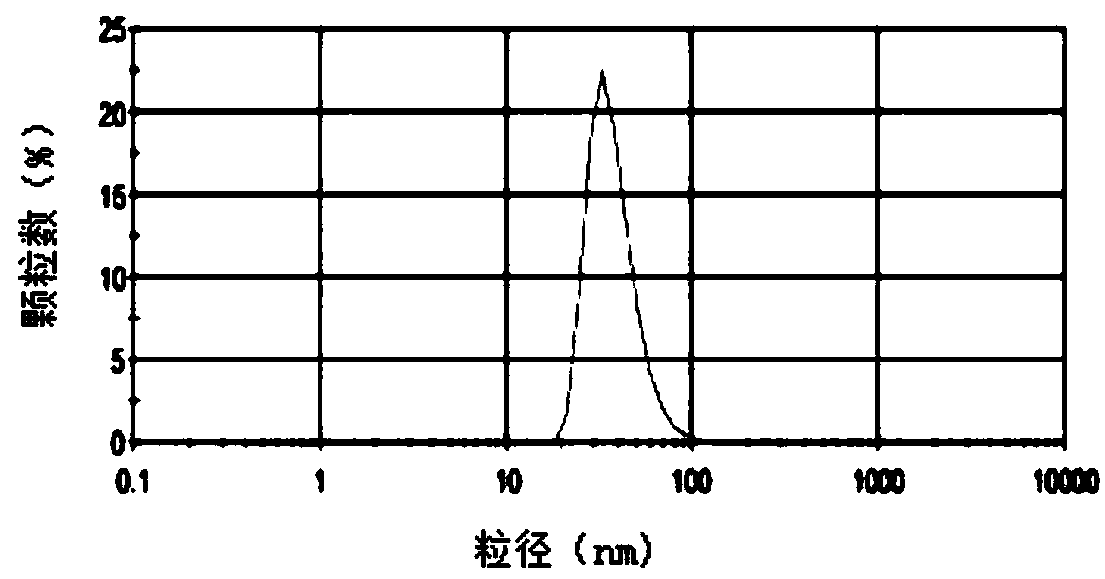

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com