Treatment system and technology for nitrate production tail gas

A treatment process and treatment system technology, which is applied in the treatment system and treatment process field of nitrate production tail gas, can solve the problems of increased environmental protection risks, increased number of droplets, and increased energy consumption of subsequent treatment sections, so as to improve the activation cycle and improve The effect of the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

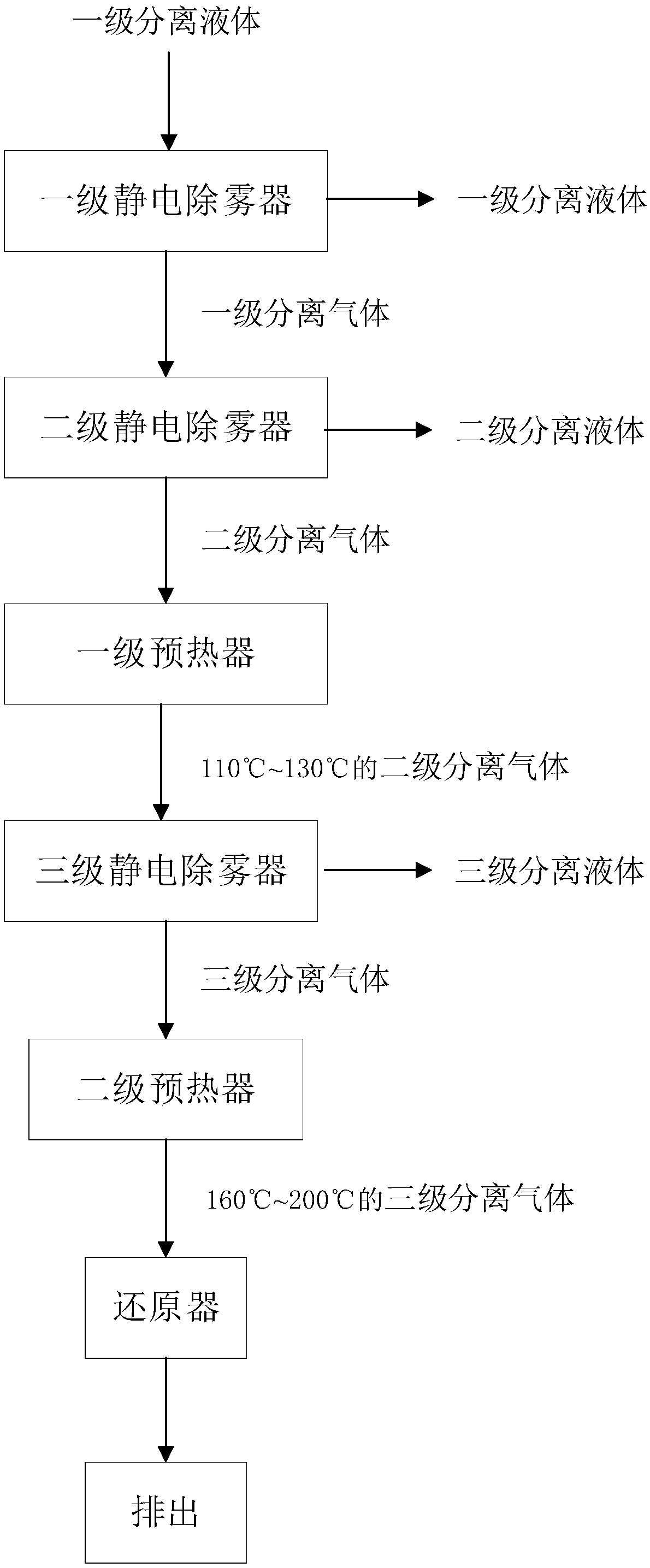

[0036] A treatment system for tail gas from nitrate production, comprising a first-stage electrostatic demister, a second-stage electrostatic demister, a first-stage preheater and a reducer arranged in sequence.

[0037] In this embodiment, a three-stage electrostatic demister is connected between the first-stage preheater and the reducer.

[0038] In this embodiment, a secondary preheater is connected between the three-stage electrostatic demister and the reducer.

Embodiment 2

[0040] Such as figure 1 Shown, a kind of process of processing tail gas of nitrate production comprises the following steps,

[0041] S1: Transport the tail gas from nitrate production at 50°C to a primary electrostatic demister with an operating voltage of 30KV to separate and obtain primary separation liquid and primary separation gas;

[0042] S2: The primary separation gas is separated by a secondary electrostatic demister with an operating voltage of 60KV to obtain a secondary separation liquid and a secondary separation gas;

[0043] S3: The temperature of the secondary separation gas is raised to 110°C and then separated by a three-stage electrostatic demister to obtain a third-stage separation liquid and a third-stage separation gas. The three-stage electrostatic demister is powered by a high-voltage high-frequency power supply. The output voltage of the high-voltage and high-frequency power supply is 110KV, and the output frequency is 200Hz;

[0044] S4: The tempera...

Embodiment 3

[0049] Such as figure 1 Shown, a kind of process of processing tail gas of nitrate production comprises the following steps,

[0050] S1: Transport the nitrate production tail gas at 50°C to the first-stage electrostatic demister with an operating voltage of 50KV to separate and obtain the first-stage separation liquid and the first-stage separation gas;

[0051] S2: The primary separation gas is separated by a secondary electrostatic demister with an operating voltage of 850KV to obtain a secondary separation liquid and a secondary separation gas;

[0052] S3: The temperature of the secondary separation gas is raised to 130°C and separated by a three-stage electrostatic demister to obtain a third-stage separation liquid and a third-stage separation gas. The three-stage electrostatic demister is powered by a high-voltage high-frequency power supply, and the The output voltage of the high-voltage and high-frequency power supply is 120KV, and the output frequency is 300Hz;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com