GFRC nonmetal sound barrier production line

A production line and sound barrier technology, applied in ceramic molding workshops, auxiliary molding equipment, supply devices, etc., can solve the problems that sound barrier panels cannot be formed at one time, cannot meet mass production, and are labor-intensive for workers. Reasonable design, reducing production cost and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

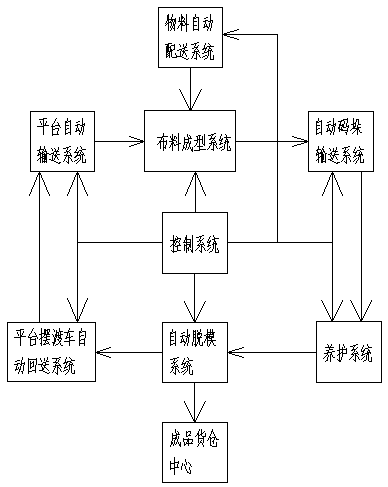

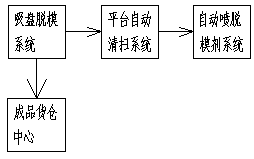

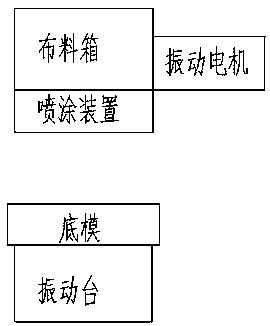

[0018] Figure 1-3 shows the first embodiment of the present invention: a GFRC non-metallic sound barrier production line, GFRC is a kind of cement mortar containing additives as the base material, glass fiber as the reinforcing material, through a special process The processed inorganic composite material has been widely used because of its light weight, large design flexibility, environmental protection, effective sound insulation, high quality, durability and fast installation. The GFRC non-metallic sound barrier production line includes control system, platform automatic conveying system, material automatic distribution system, cloth forming system, automatic palletizing conveying system, maintenance system, automatic demoulding system and platform shuttle car automatic return system, the platform automatic conveying system, material automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com