Method for preparing mesocarbon microbeads by cyclic pyrocondensation polymerization of byproduct asphalt

A technology of mesophase carbon microspheres and thermal condensation, which is applied in the preparation/purification of carbon, etc., can solve the problems of the influence of mesophase carbon microsphere material properties, the insignificant increase in product yield, and the low use efficiency of by-product pitch. Achieve the effects of improving particle size distribution and surface morphology, reducing production costs, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029]The invention provides a method for preparing mesophase carbon microspheres, comprising: step 1, mixing coal-based pitch, by-product pitch, and a first solvent to obtain a mixed material, wherein the by-product pitch is a thermal polycondensation reaction After separating the pitch obtained after the mesophase carbon microspheres, the first solvent is an aromatic hydrocarbon, and / or solvent oil containing aromatic hydrocarbons; step 2, heating the mixed material to the reaction temperature for thermal polycondensation reaction, Obtain the polycondensation pitch containing mesophase carbon microspheres; step 3, extract and separate the polycondensation pitch in the second solvent to obtain solid phase components and liquid phase components; step 4, extract the solid phase The components are dried to obtain the mesophase carbon microspheres; the liquid phase components are distilled to obtain by-product pitch and recover the second solvent.

[0030] The preparation method ...

Embodiment 1

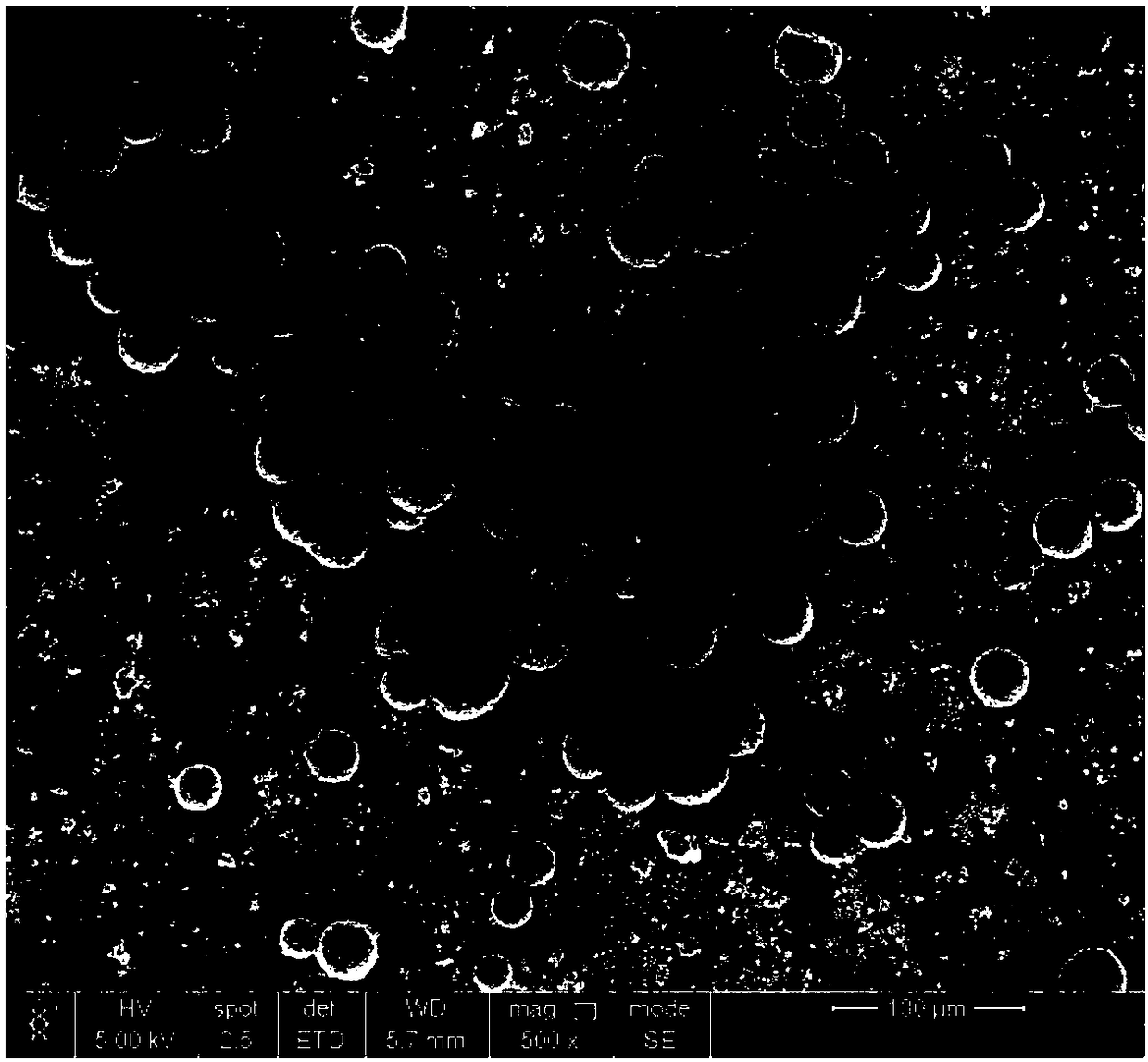

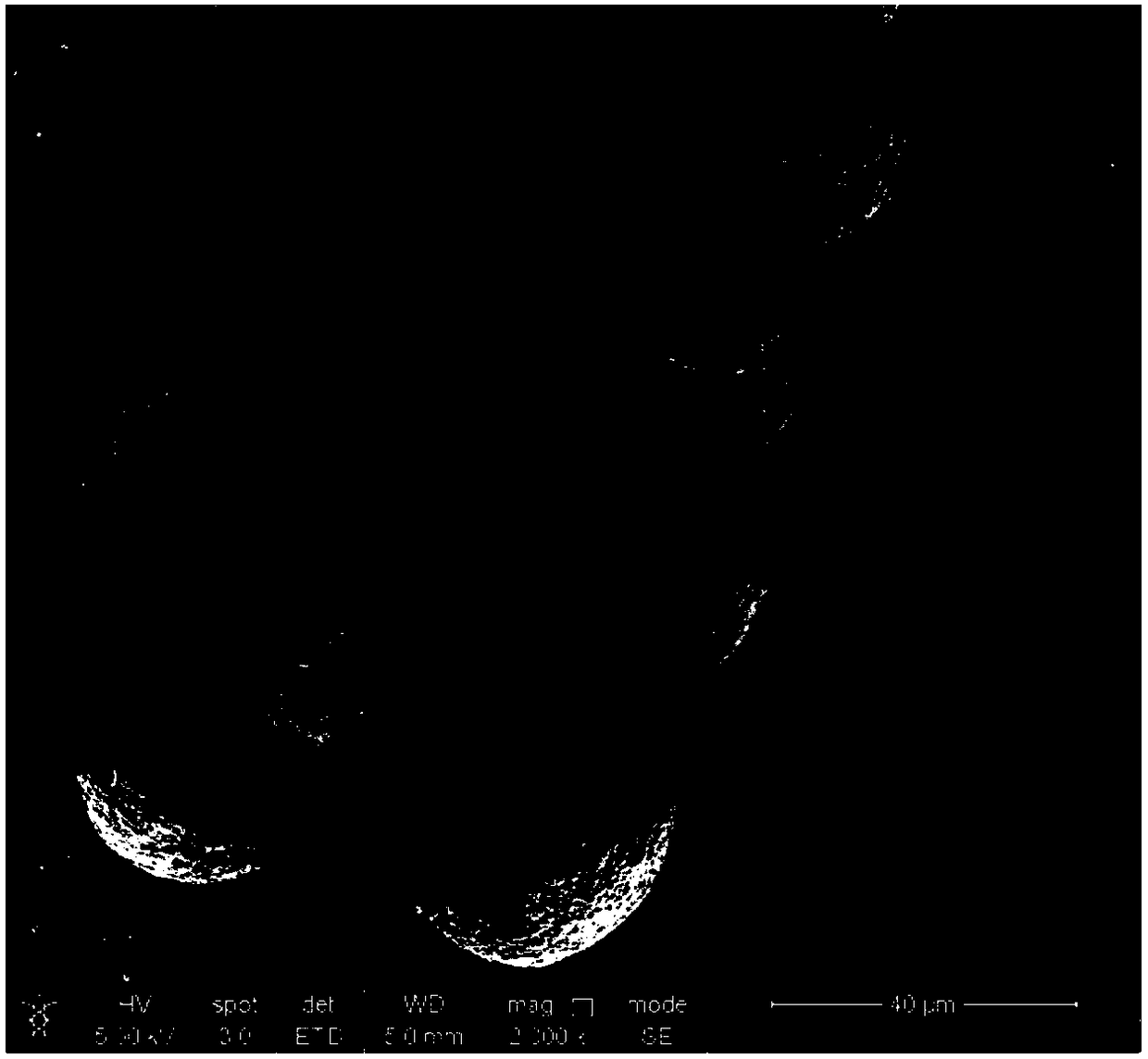

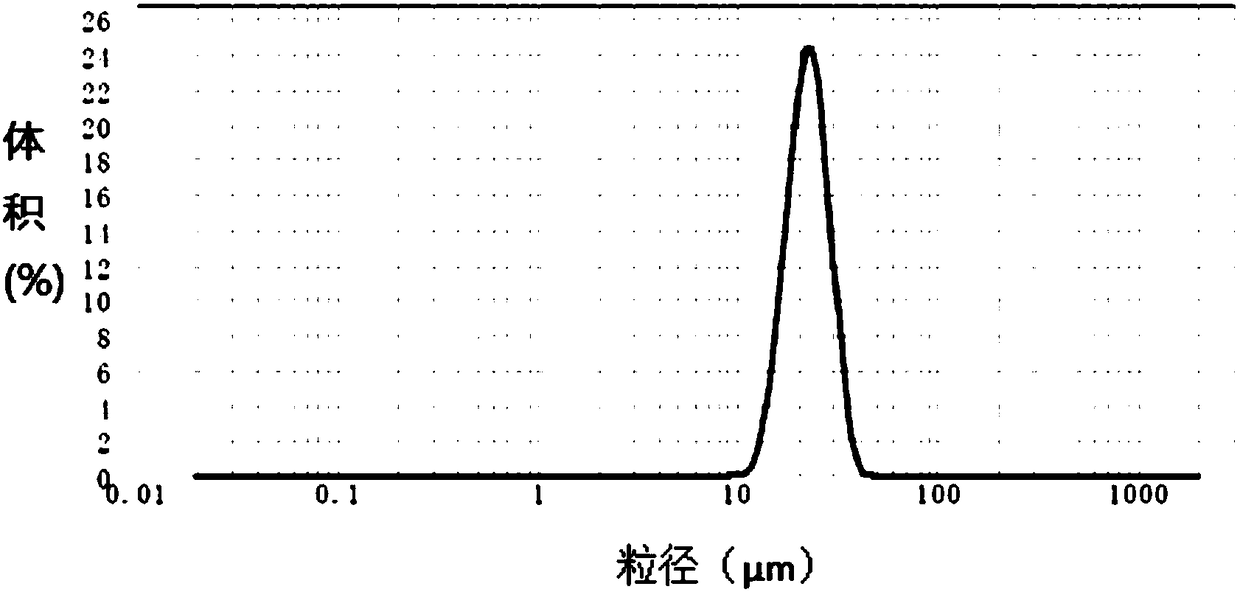

[0044] Add medium-temperature asphalt with a softening point of 85°C and by-product asphalt into a stainless steel reactor in a mass ratio of 2:1, add anthracene oil to the total asphalt at a mass ratio of 1:9, self-boost after nitrogen purging, and normal temperature to 350 The average temperature rise rate of ℃ is 8°C / min. After staying at a constant temperature of 350°C for 1 hour, the temperature rises to 440°C at a rate of 2°C / min and stays at a constant temperature for 8 hours. After the reaction is completed, the solvent pyridine is added for extraction at 80°C. The volume ratio of the polycondensation pitch to the carbon-containing microspheres is 4:1, and the solid insolubles are obtained by filtering through a filter with a pore size of 5 μm, and the solid insolubles are dried at 80° C. and a vacuum of 1 KPa to obtain mesophase carbon microspheres. The mass yield (based on the raw material) is 42.2%, the D10 particle size is 1.0 μm, the D50 particle size is 19.0 μm, a...

Embodiment 2

[0046] Add medium-temperature asphalt with a softening point of 85°C and by-product asphalt into a stainless steel reactor in a mass ratio of 6:1, the mass ratio of the amount of anthracene oil added to the total asphalt is 1:14, and the pressure is stabilized at 1 MPa after nitrogen purging. The average heating rate at 320°C is 7°C / min. After staying at a constant temperature of 320°C for 1.5 hours, the temperature rises to 420°C at a rate of 1.5°C / min, and stays at a constant temperature for 8 hours. After the reaction, add washing oil and extract at 120°C. The volume ratio of the washing oil to the polycondensation pitch of the carbon-containing microspheres is 2:1, and the solid insoluble matter is obtained by filtering through a filter with a pore size of 5 μm, and the solid insoluble matter is dried at 120 ° C and a vacuum of 1 KPa to obtain the mesophase carbon microspheres. Balls, the mass yield (based on raw materials) is 44.4%, the D10 particle size is 1.7 μm, the D50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com