A kind of method for comprehensively extracting lithium potassium boron from oil field brine

A comprehensive extraction, lithium potassium boron technology, applied in chemical instruments and methods, boron compounds, boron oxide compounds, etc., to achieve low-cost economic benefits and social value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

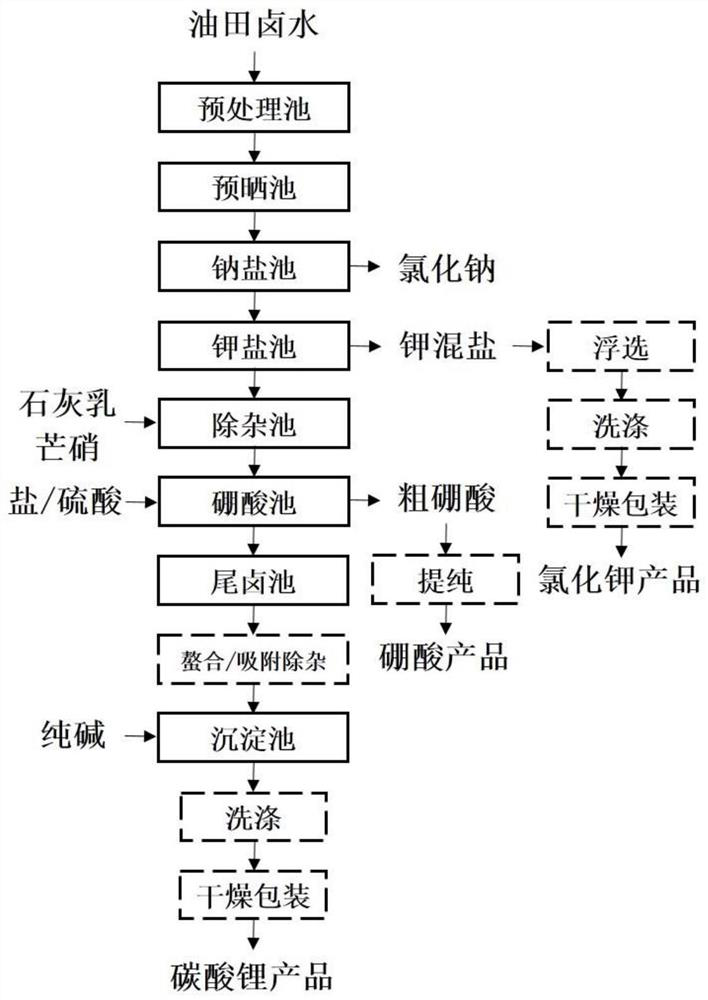

[0056] A method for comprehensively extracting lithium potassium boron from oil field brine, specifically comprising the following steps, the process flow is as follows figure 1 Shown:

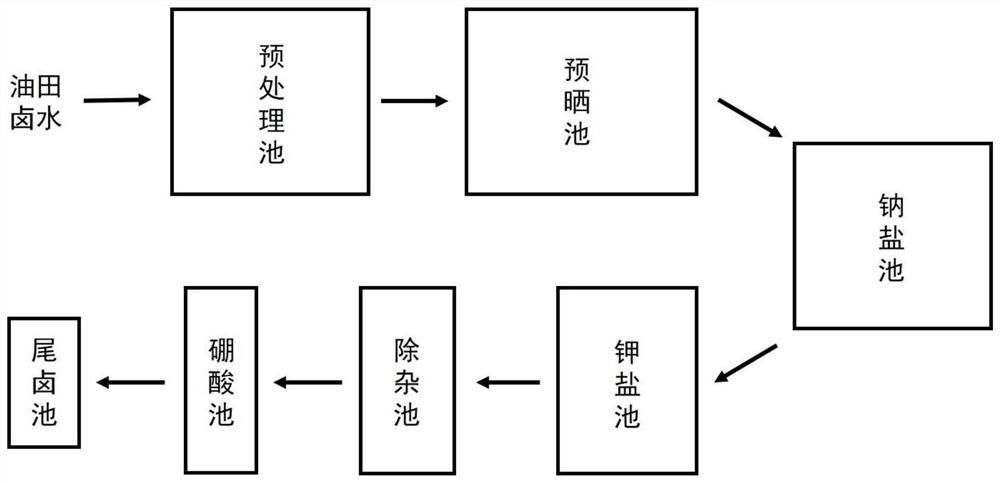

[0057] 1) Set up the pretreatment pool, pre-drying pool, sodium salt pool, potassium salt pool, impurity removal pool, boric acid pool and tailing brine pool in sequence, such as figure 2 shown;

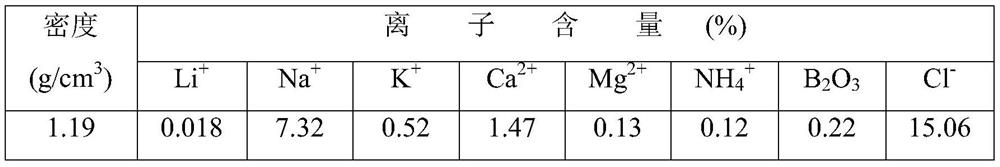

[0058] 2) Take the oilfield brine in a certain area of Qinghai (the chemical composition of the brine is shown in Table 1 below), pump it into the pretreatment tank through the natural sedimentation of mud and sand, and use the oil-water separator to separate the oil and water to obtain clarified pretreated oilfield brine;

[0059] Table 1 Chemical composition of oilfield brine

[0060]

[0061] 3) Pour the oil field brine after the pretreatment that step 2) obtains into the pre-drying pool, and carry out natural evaporation in the sun, and wait for Na + When it is close to saturation, pour ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com