Sodium stearyl fumarate auxiliary material and preparation method thereof

A technology of sodium stearyl fumarate and auxiliary materials is applied in directions such as carboxylate preparation, chemical instruments and methods, preparation of organic compounds, etc., and can solve problems such as increasing production cost and time, unfavorable industrialized production, and tedious synthesis process, etc. To achieve the effect of simplifying the preparation process and post-processing steps, reducing the residual solvent components, and improving the total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

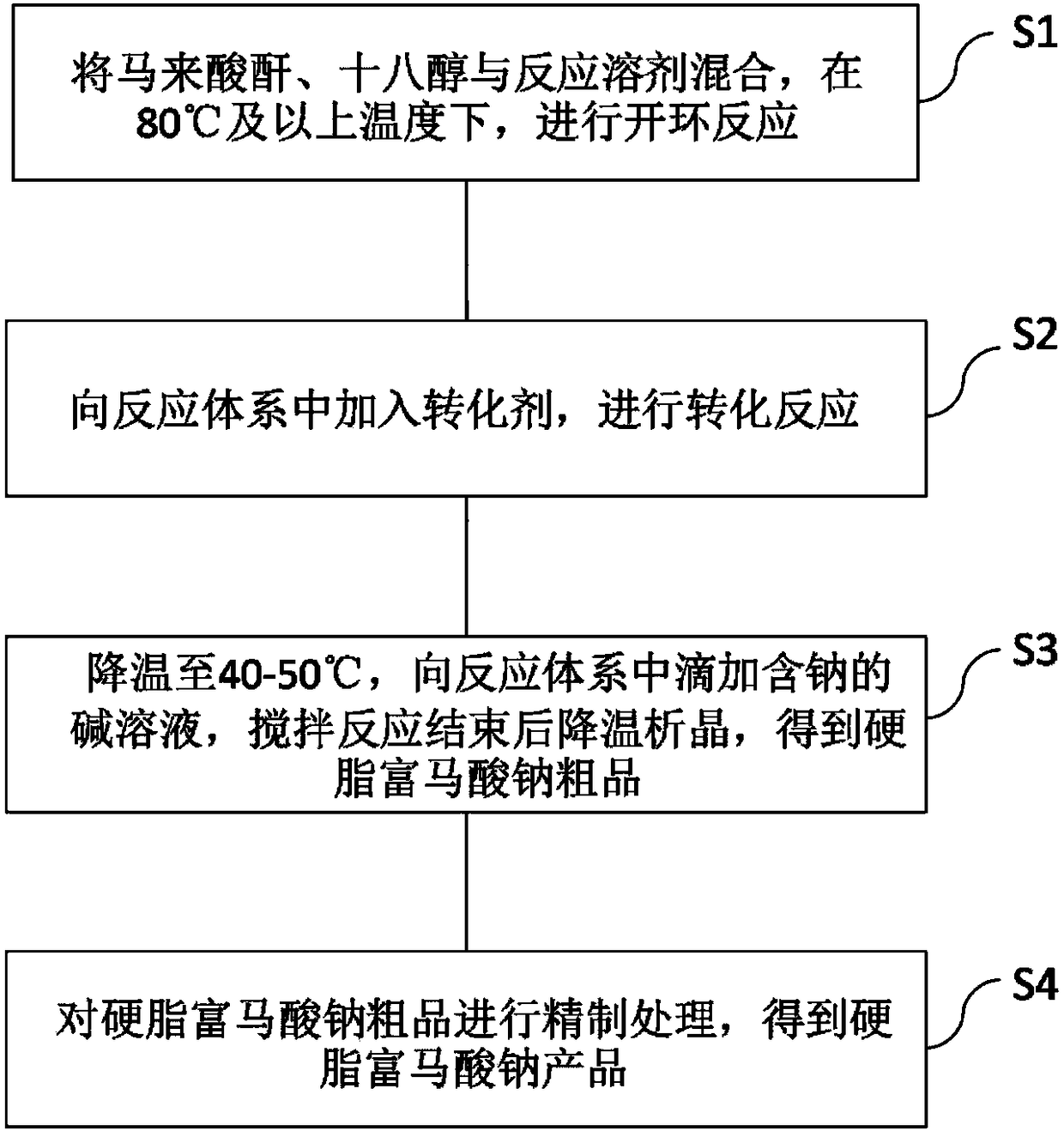

[0028] Such as figure 1 Shown, the invention provides a kind of preparation method of sodium stearyl fumarate auxiliary material, comprises the following steps:

[0029] S1. Mix maleic anhydride, stearyl alcohol and a reaction solvent, and perform a ring-opening reaction at a temperature of 80° C. or above;

[0030] S2, adding a conversion agent to the reaction system to perform a conversion reaction;

[0031] S3, cooling down to 40-50°C, adding a sodium-containing alkali solution dropwise to the reaction system, cooling down and crystallizing after the stirring reaction is completed, and obtaining crude sodium stearyl fumarate;

[0032] S4. Refining the crude sodium stearyl fumarate to obtain a sodium stearyl fumarate product.

[0033] Following is the process route of the present invention:

[0034]

[0035] In one embodiment, in step S1, the present invention uses maleic anhydride and stearyl alcohol as raw materials, puts them in a reaction solvent, raises the temper...

Embodiment 1

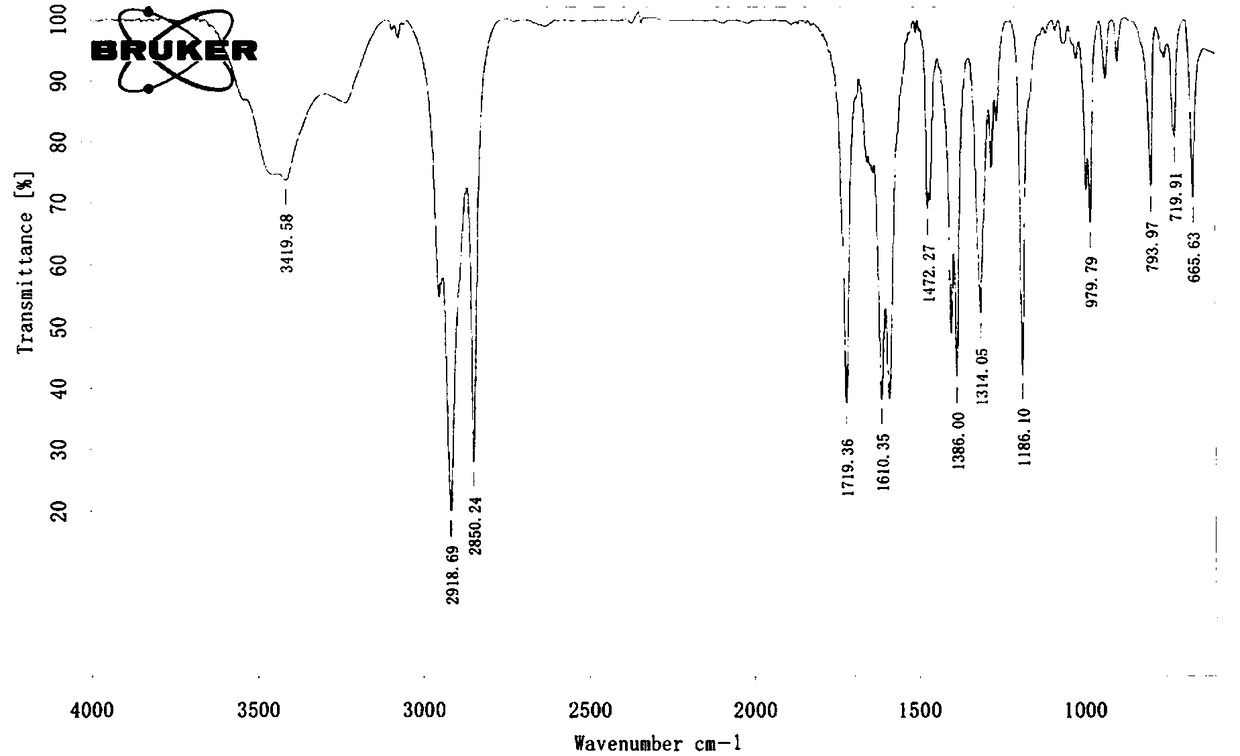

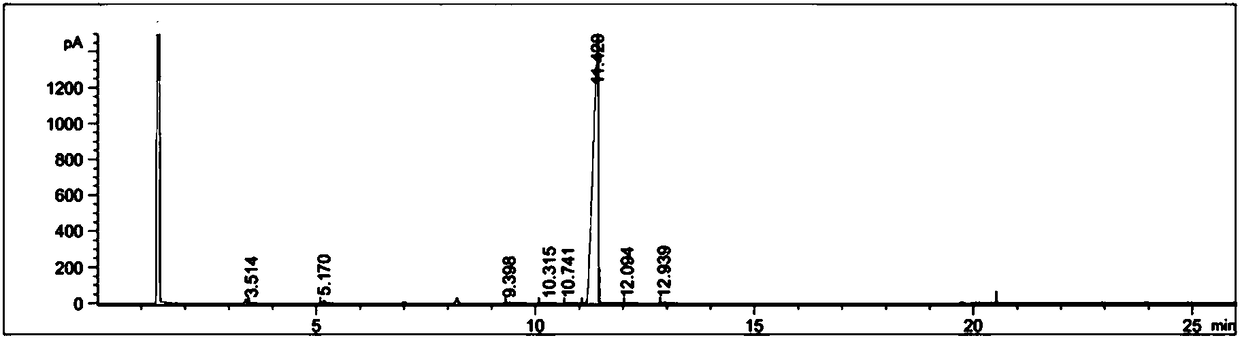

[0044] The preparation of embodiment 1 sodium stearyl fumarate

[0045] Add 103.0g of maleic anhydride, 270.00g of stearyl alcohol and 1000mL of toluene into the reaction vessel, and heat to 85°C for 12 hours to react. To the reaction system, add 10% hydrochloric acid / thiourea solution (the mass ratio of hydrochloric acid and thiourea is 1:1), react at 80°C for 16 hours, and detect by gas phase: Intermediate II / Intermediate I is 99.5% . Subsequently, the temperature was lowered to 45°C, and 320 mL of an aqueous solution containing 51.5 g of sodium hydroxide was added dropwise to the reaction system. After 1 hour, the dropwise addition was completed. Stirring was continued for 1 hour, cooled to room temperature, stirred for 1 hour, and filtered to obtain stearyl fumar Crude Sodium Acid. Add the crude product and 2Kg ethanol into a reaction vessel, raise the temperature to 50°C, and beat at this temperature for 7 hours, cool down to 20°C, filter, wash with ethanol, and dry t...

Embodiment 2

[0046] The preparation of embodiment 2 sodium stearyl fumarate

[0047] 123.5 g of maleic anhydride, 324.06 g of stearyl alcohol and 1200 mL of cyclohexane were added to the reaction vessel, and the mixture was heated to 90° C. for 15 hours to react. To the reaction system, add 8% hydrochloric acid / thiourea solution (the mass ratio of hydrochloric acid and thiourea is 1:1), and react at 72° C. for 10 hours. Subsequently, the temperature was lowered to 48°C, and 650 mL of an aqueous solution containing 49.5 g of sodium hydroxide was added dropwise to the reaction system. After 1 hour, the dropwise addition was completed. Stirring was continued for 1 hour, cooled to room temperature, stirred for 2 hours, and filtered to obtain stearyl fumar Crude Sodium Acid. Add the crude product and 4.2Kg ethanol into a reaction vessel, raise the temperature to 50°C, and beat for 5 hours at this temperature, cool down to 22°C, filter, wash with ethanol, and vacuum freeze-dry the obtained so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com