Low-frequency sound absorption rubber composite material based on cavity structure and preparation method thereof

A technology of sound-absorbing rubber and composite materials, which can be used in sound-producing equipment, instruments, etc., can solve problems such as narrow sound-absorbing frequency band, and achieve strong absorption, excellent low-frequency sound absorption effect, and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

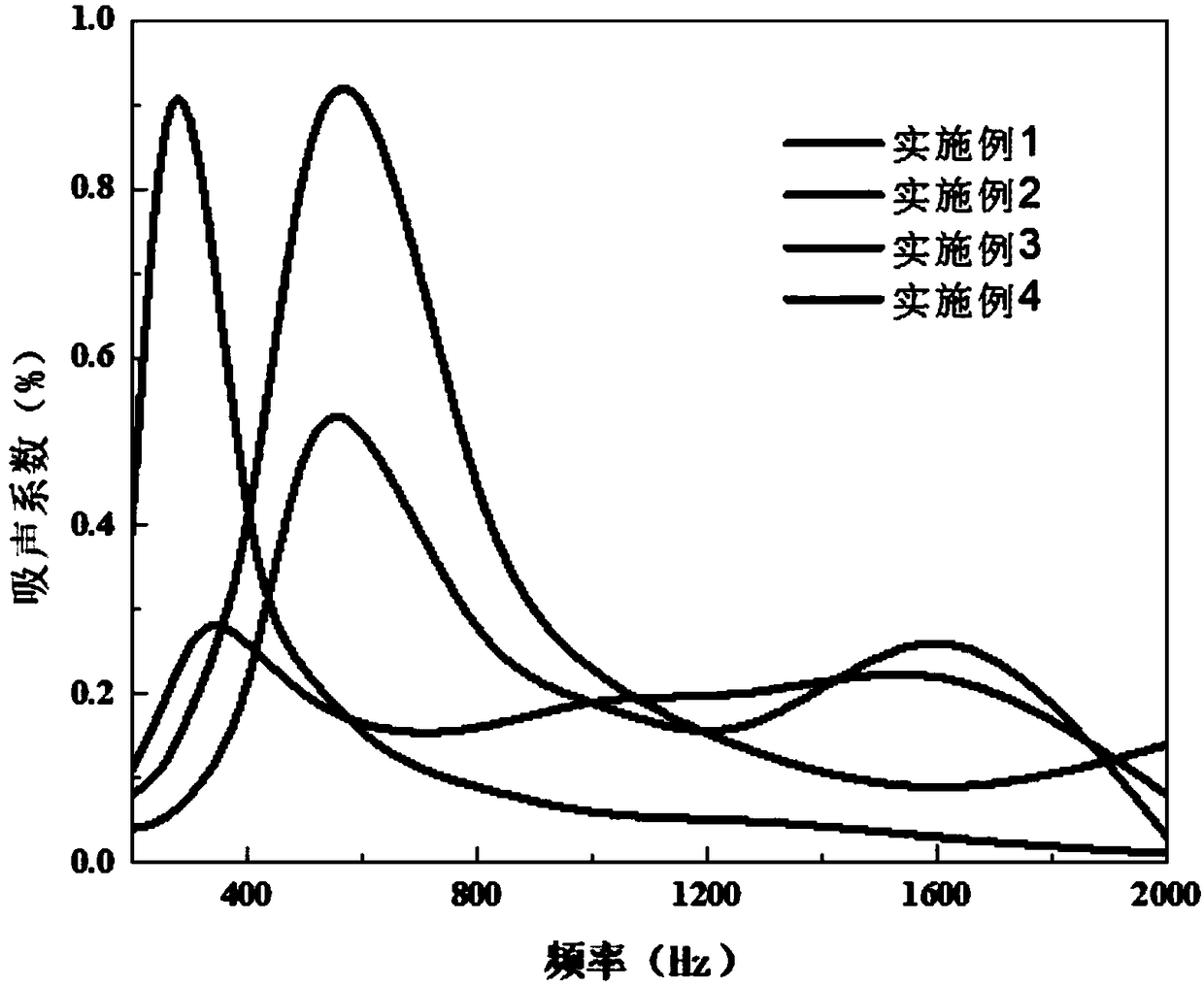

Examples

Embodiment 1

[0023] A method for preparing a low-frequency sound-absorbing rubber composite material based on a cavity structure. The preparation steps are as follows:

[0024] (1) Modification of lead zirconate titanate powder: take a certain amount of lead zirconate titanate powder and heat it in a muffle furnace at a constant temperature of 1200°C for 2 hours, and then place it in a ball mill for 15 minutes;

[0025] (2) Preparation of piezoelectric composite material: In the open mill, add 100 phr of nitrile rubber, 3 phr of nano zinc oxide, 0.75 phr of stearic acid, 0.75 phr of zinc stearate, 0.6 phr of antioxidant RD, and 1.0 phr of accelerator TMTD. , Accelerator CZ0.5phr, conductive carbon black 0.8phr, carbon black 9.2phr, lead zirconate titanate 127phr and sulfur 1.5phr, mixed under 80℃ for 25min to obtain a rubber compound, and the rubber compound is at 160℃, 15MPa conditions Vulcanize for 15 minutes to obtain piezoelectric composite material;

[0026] (3) Composite structure of sound...

Embodiment 2

[0029] A method for preparing a low-frequency sound-absorbing rubber composite material based on a cavity structure. The preparation steps are as follows:

[0030] (1) Modification of lead zirconate titanate powder: a certain amount of lead zirconate titanate powder is heat-treated in a muffle furnace at a constant temperature of 1200°C for 3 hours, and then placed in a ball mill for ball milling for 25 minutes;

[0031] (2) Preparation of piezoelectric composite material: Add 100phr of nitrile rubber, 4phr of nano zinc oxide, 1.2phr of stearic acid, 1.2phr of zinc stearate, antiaging agent RD 0.8phr, and accelerator TMTD 1.2phr in the open mill. , Accelerator CZ 0.6phr, conductive carbon black 1.0phr, carbon black 9.0phr, lead zirconate titanate 127phr and sulfur 1.2phr, and lead zirconate titanate powder is added at the same time, and mixed at 80℃ for 25min to obtain a mixed rubber. The rubber compound was vulcanized at 170°C and 15MPa for 20 minutes to obtain piezoelectric compo...

Embodiment 3

[0035] A method for preparing a low-frequency sound-absorbing rubber composite material based on a cavity structure. The preparation steps are as follows:

[0036] (1) Modification of lead zirconate titanate powder: a certain amount of lead zirconate titanate powder is heat-treated in a muffle furnace at a constant temperature of 1200°C for 2 hours, and then placed in a ball mill for 25 minutes;

[0037] (2) Preparation of piezoelectric composite material: add 100phr of nitrile rubber, 4phr of nano zinc oxide, 1.2phr of stearic acid, 1.2phr of zinc stearate, antiaging agent RD 0.8phr, and accelerator TMTD 1.6phr in the open mill. , Accelerator CZ 0.8phr, conductive carbon black 1.0phr, carbon black 9.0phr, lead zirconate titanate 190phr and sulfur 1.2phr, mixed under 80℃ for 25min to obtain a rubber compound, and the rubber compound is at 170℃, 15MPa conditions Vulcanize for 20 minutes to obtain piezoelectric composites;

[0038] (3) Composite structure of sound-absorbing material: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com