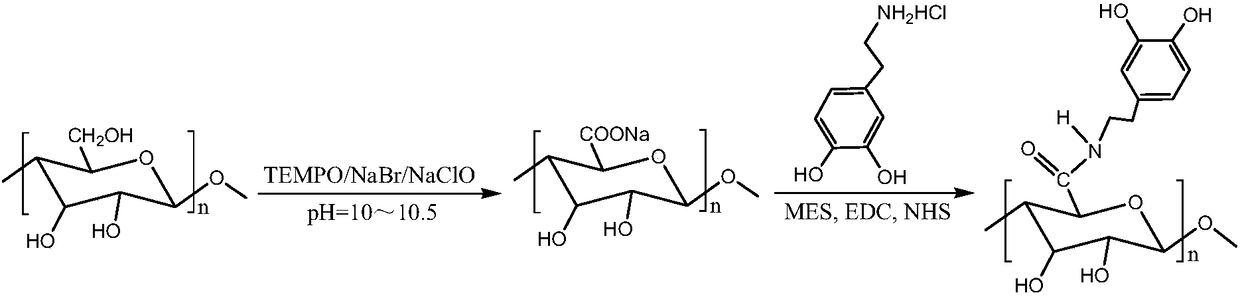

Cellulose-based dopa adhesive and preparation method thereof

A technology based on dopa-based adhesives and cellulose, which is applied in the field of cellulose-based dopa-based adhesives and its preparation, and can solve problems such as environmental and health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 5g of cellulose into 1000mL N,N-dimethylacetamide / lithium chloride dissolution system, heat to 100°C in an oily pan and stir for 2 hours, then stir at room temperature for one day to obtain a cellulose solution, and use the cellulose solution to Centrifuge at 8000rpm for 15 minutes to remove a small amount of insoluble matter to obtain a cellulose solution. Use a separatory funnel to drop 10L of ultrapure water into the cellulose solution, gradually precipitate the cellulose and filter to obtain regenerated cellulose powder.

[0016] Weigh 4.5g of the prepared regenerated cellulose powder and disperse evenly with 450mL of ultrapure water, add 0.144g of TMEPO and 11.5g of NaBr, use 0.1mol / L sodium hydroxide solution or hydrochloric acid to control the pH value at 10.2, and add 103.5 mLNaClO solution and maintain the pH value at 10.2 until the pH value no longer changes, terminate the reaction with 5 mL absolute ethanol, and finally dialyze with a dialysis bag and free...

Embodiment 2

[0021] Add 5g of cellulose to 500mL of ionic liquid 1-butyl-3-methylimidazolium chloride, heat to 100°C in an oil pan and stir for 2 hours, then stir at room temperature for one day to obtain a cellulose solution, and centrifuge the cellulose solution Centrifuge at 8000rpm for 15 minutes to remove a small amount of insoluble matter to obtain a cellulose solution. Use a separatory funnel to drop 10L of ultrapure water into the cellulose solution, gradually precipitate the cellulose and filter to obtain a cellulose powder.

[0022] Weigh 4.5g of the prepared cellulose powder and disperse evenly with 450mL ultrapure water, add 0.144g TMEPO and 11.5g NaBr, control the pH value at 10.2 with 0.1mol / L sodium hydroxide solution or hydrochloric acid, and add 103.5mL NaClO after it is dissolved solution and maintain the pH value at 10.2 for reaction until the pH value no longer changes, terminate the reaction with 5 mL of absolute ethanol, and finally dialyze with a dialysis bag and free...

Embodiment 3

[0025] Dissolve 5.5g of commercially available oxidized cellulose (with a carboxyl content of more than 1.5mmol / g) in 550mL of 2-(N-morpholine)ethanesulfonic acid buffer, and after it dissolves, add 6.4g of N-hydroxysuccinimide (NHS) and 10.7g 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide (EDC) to activate the carboxyl group for 1 hour, and finally add 10.5g dopamine hydrochloride to react at room temperature for 12 hours, then move to dialysis The bag was dialyzed and freeze-dried to obtain a cellulose-based dopa adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com