Oil-soluble Fe3O4/modified graphene oxide composite material, and preparation method and application thereof

A technology of ferric tetroxide and composite materials, applied in the field of materials, can solve problems such as difficulty in dispersion, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

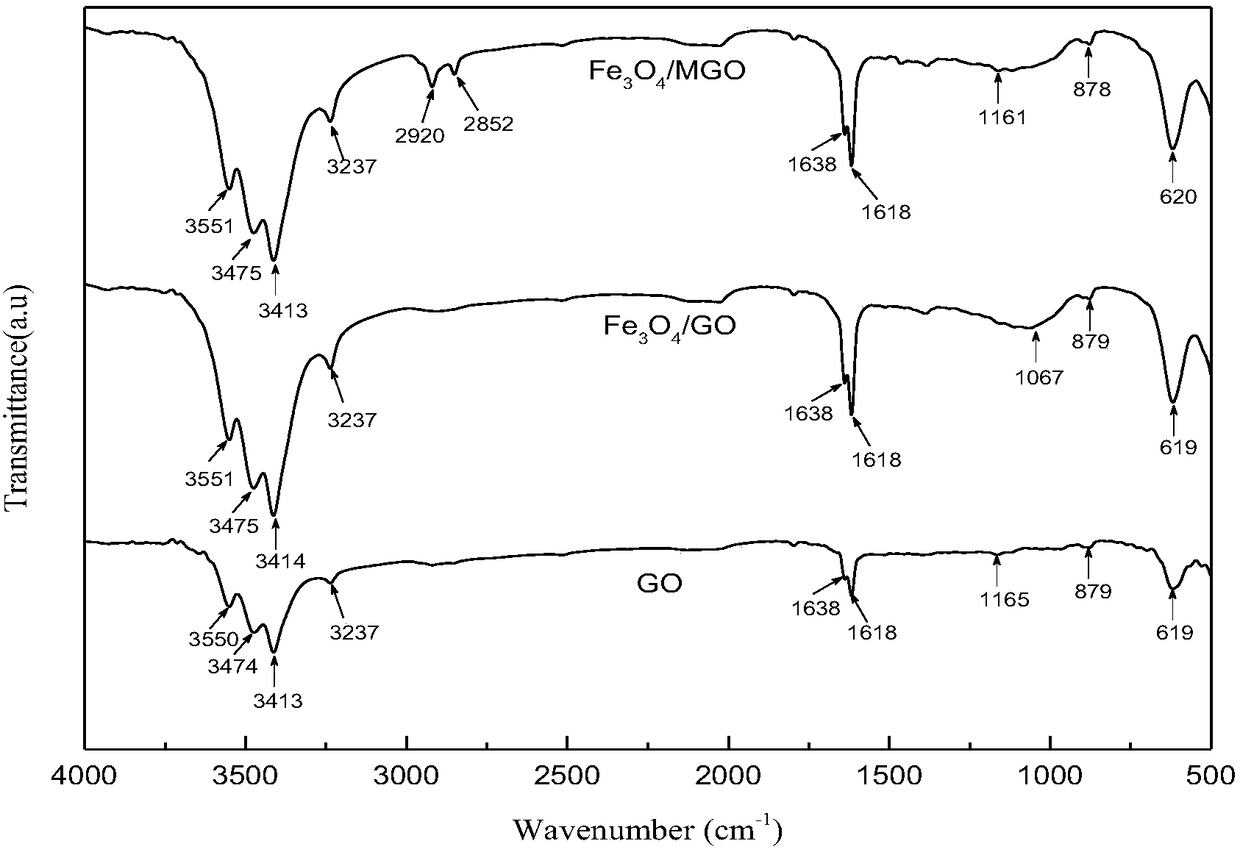

[0030] The invention provides a kind of preparation method of oil-soluble iron ferric oxide / modified graphene oxide composite material, comprises the following steps:

[0031] A) under alkaline conditions, the aqueous solution of graphene oxide and containing Fe 3+ and Fe 2+ After the aqueous solution is mixed, carry out heating reaction, obtain ferric oxide / graphene oxide composite material;

[0032] B) The ferric oxide / graphene oxide composite material is mixed with alkylamine to obtain oil-soluble ferric oxide / modified graphene oxide composite material, and the alkylamine is selected from laurylamine, deca Triamine, tetradecylamine, hexadecylamine, octadecylamine or diisotridecylamine.

[0033] The present invention configures the aqueous solution of graphene oxide and contains Fe 3+ and Fe 2+ of aqueous solution. Wherein, the configuration method of the aqueous solution of the graphene oxide is:

[0034] The graphene oxide is mixed with deionized water and ultrasonic...

Embodiment 1

[0066] In this example, Fe 3+ , Fe 2+ Co-precipitate with graphene oxide to obtain water-soluble ferric oxide / graphite oxide, and then self-assemble with ferric oxide / graphite oxide and alkylamine to prepare oil-soluble ferric oxide / modified graphene oxide composite Material. Specific steps are as follows:

[0067] Under the condition of ice bath, 4g of sodium nitrate and 4g of graphite powder were added to 140mL of 98% concentrated sulfuric acid. Slowly add 24 g of potassium permanganate under magnetic stirring. The mixture was reacted overnight at room temperature, raised to 35°C for 35 minutes, then raised to 80°C and kept for 10 minutes. The mixture was slowly oxidized and turned bright yellow. The temperature was lowered to 60°C, and 400 mL of deionized water was slowly added to keep the reaction temperature not exceeding 100°C. The mixture was centrifuged at 5000r / min, washed several times with 5% hydrochloric acid, and finally washed with ultrapure water to remove...

Embodiment 2

[0076] The preparation method of this embodiment is the same as that of Example 1, except that FeCl 3 ·6H 2 O and FeCl 2 4H 2 The consumption of O is respectively 1g and 2.0g, and the ferric oxide content is higher in the sample that example 2 prepares, and the composite material that obtains is similar to the result of embodiment 1, promptly has good external magnetic field responsiveness, in liquid paraffin Stable dispersion performance and good thermal conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat of phase change | aaaaa | aaaaa |

| Phase transition peak temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com