Microbial compound fungicide for degrading waste gas of rubber plant and preparation method and application thereof

A composite bacterial agent and rubber factory technology, which is applied in the field of microbial composite bacterial agent for degrading waste gas from rubber factories and its preparation, which achieves the effects of low cultivation cost, easy use and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A microbial composite bacterial agent for degrading waste gas from a rubber factory, comprising, in parts by mass, 10 parts of Bacillus atrophaeus, 5 parts of Stenobacter brevis, 2 parts of Photobacterium luminescent, 2 parts of Pseudomonas alcaligenes, and Cladobacillus pantothenicis Bacillus 2 parts, Pseudomonas putida 10 parts.

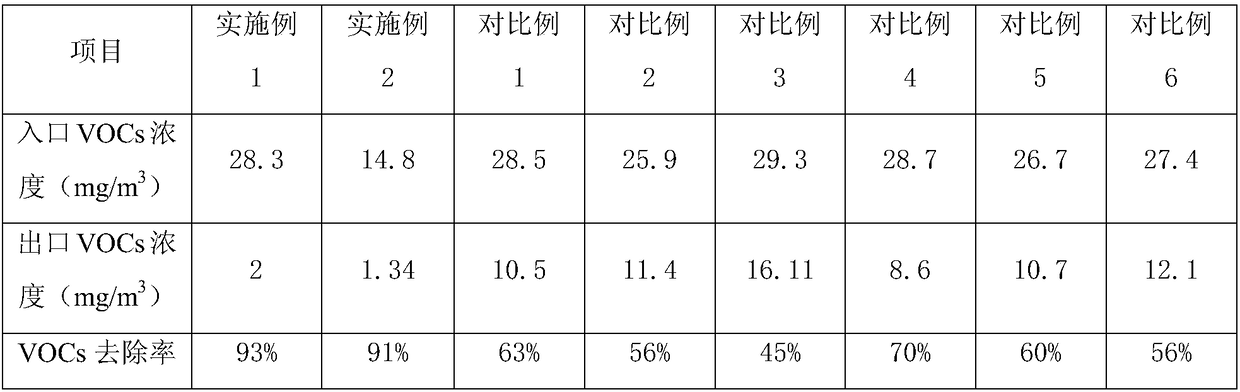

[0031] Application of exhaust gas treatment in the mixing workshop of tire factory: inoculate the microbial compound bacterial agent into the biological box of the biological trickling filter tower, the inoculation amount is 10% of the circulating water quality in the water tank of the biological trickling filter tower, and the waste gas from the inlet of the biological trickling filter tower The waste gas is passed through, and the concentration of VOCs in the waste gas at the inlet is detected before treatment, and the concentration of VOCs in the waste gas at the outlet of the biological trickling filter is detected one week later. The te...

Embodiment 2

[0033] A microbial composite bacterial agent for degrading waste gas from a rubber factory, comprising, calculated in parts by mass, 5 parts of Bacillus atrophaeus, 5 parts of Stenobacter brevis, 5 parts of Photobacterium luminescent, 5 parts of Pseudomonas alcaligenes, and Cladobacillus pantothenicis Bacillus 5 parts, Pseudomonas putida 5 parts.

[0034] Application of exhaust gas treatment in the vulcanization workshop of rubber products factory: inoculate the microbial compound bacterial agent into the biological tank of the biological trickling filter tower, the inoculation amount is 5% of the circulating water quality in the biological trickling filter tower water tank, and the waste gas from the biological trickling filter tower exhaust gas inlet The waste gas is passed through, and the concentration of VOCs in the waste gas at the inlet is detected before treatment, and the concentration of VOCs in the waste gas at the outlet of the biological trickling filter is detecte...

Embodiment 3

[0051] The preparation method of the microbial composite bacterial agent, the specific preparation steps are as follows:

[0052] (1) Determination of the composition of waste gas from rubber factories

[0053] According to the gas sampling method of GB16157-1996 "Sampling Method for Particulate Pollutants and Gaseous Pollutants in Exhaust from Stationary Pollution Sources", waste gas from rubber factories is collected, and the recovered gas is analyzed by GC-MS. The analysis results show that the main components of waste gas from rubber factories are Toluene and xylene;

[0054] (2) Sampling and preparation of medium

[0055] Take the bottom sludge discharged from the rubber factory as the inoculum, settle the fresh bottom sludge for 30min, and take 50mL of thick bottom sludge with sterile water to make 10 -7 , 10 -8 , 10 -9Gradient dilution, for use, prepare the selective medium with toluene and xylene as carbon source;

[0056] The selective medium components are: tolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com