Salt Bath Nitriding Treatment Method for Compressor High Speed Steel Sliding Vane

A salt bath nitriding and treatment method technology, applied in the chemical field, can solve the problems of increased production cost, increased production cycle, and the inability to guarantee that the white layer will not form, and achieve the effect of high control precision and controlled compound formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

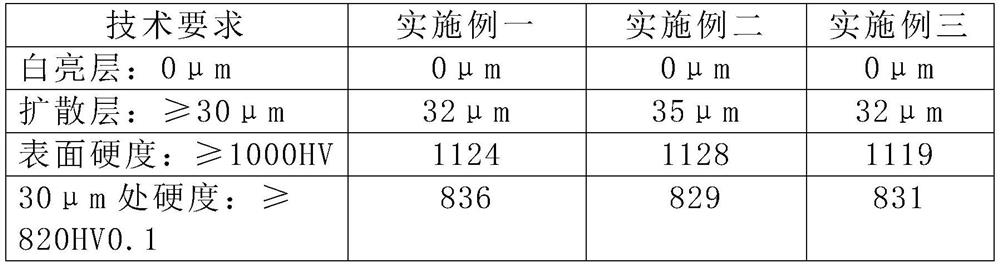

Examples

Embodiment 1

[0016] A salt-bath nitriding treatment method for a compressor high-speed steel sliding vane is carried out in the following order:

[0017] The first step of pre-treatment: including clamping and cleaning the workpiece; specifically, the clamping of the workpiece is to place the R side of the compressor high-speed steel slide plate upwards and slightly inclined in the fixture; then place the compressor high-speed steel Put the jig of the slide into the ultrasonic cleaning machine for cleaning, take it out and air dry after cleaning. Compared with cleaning first and then clamping, the process of clamping the workpiece first and then cleaning the workpiece can avoid additional pollution of the blade during clamping, which will affect product quality.

[0018] The second step of preheating: put the fixture with the workpiece into the salt bath furnace for preheating, the temperature is 360°C, and the time is 15 minutes.

[0019] The third step of salt bath nitriding treatment: ...

Embodiment 2

[0023] A salt-bath nitriding treatment method for a compressor high-speed steel sliding vane is carried out in the following order:

[0024] The first step of pre-treatment: including clamping and cleaning the workpiece; specifically, the clamping of the workpiece is to place the R side of the compressor high-speed steel slide plate upwards and slightly inclined in the fixture; then place the compressor high-speed steel Put the jig of the slide into the ultrasonic cleaning machine for cleaning, take it out and air dry after cleaning. Compared with cleaning first and then clamping, the process of clamping the workpiece first and then cleaning the workpiece can avoid additional pollution of the blade during clamping, which will affect product quality.

[0025] The second step of preheating: put the fixture with the workpiece into the salt bath furnace for preheating, the temperature is 380°C, and the time is 14 minutes.

[0026] The third step of salt bath nitriding treatment: ...

Embodiment 3

[0030] A salt-bath nitriding treatment method for a compressor high-speed steel sliding vane is carried out in the following order:

[0031] The first step of pre-treatment: including clamping and cleaning the workpiece; specifically, the clamping of the workpiece is to place the R side of the compressor high-speed steel slide plate upwards and slightly inclined in the fixture; then place the compressor high-speed steel Put the jig of the slide into the ultrasonic cleaning machine for cleaning, take it out and air dry after cleaning. Compared with cleaning first and then clamping, the process of clamping the workpiece first and then cleaning the workpiece can avoid additional pollution of the blade during clamping, which will affect product quality.

[0032] The second step of preheating: put the fixture with the workpiece into the salt bath furnace for preheating, the temperature is 400°C, and the time is 12 minutes.

[0033] The third step of salt bath nitriding treatment: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com