Mine underground tailing water in-situ processing method and retaining wall capable of being filled by osmotic response

A treatment method and water in-situ technology, which is applied in the in-situ treatment of mine tailings water and the field of permeable reaction filling retaining wall, can solve the problems of decreased filling efficiency, insufficient processing capacity to meet the underground filling volume, and high processing cost, and achieve Prevent pollution, low operation and maintenance costs, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

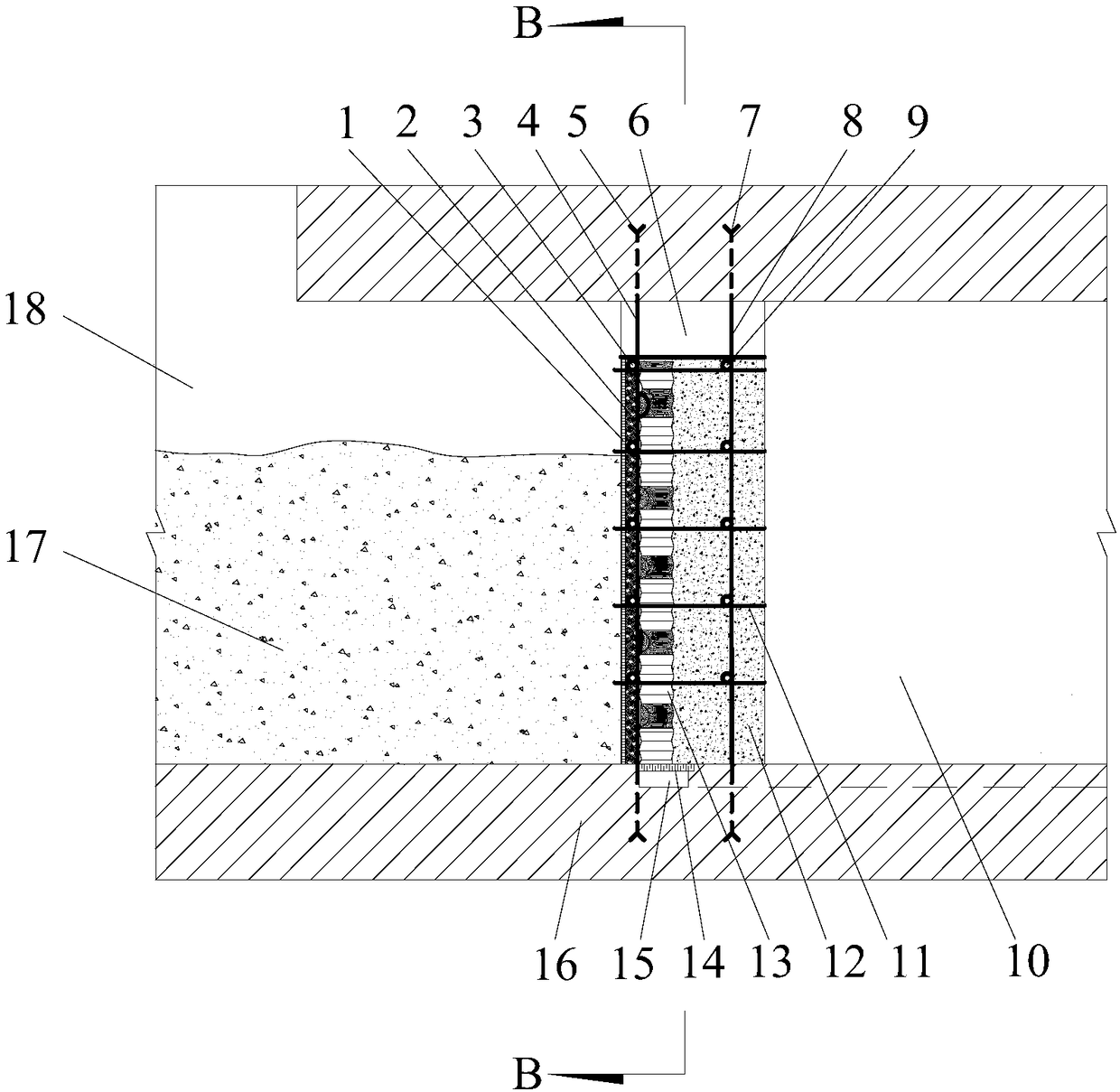

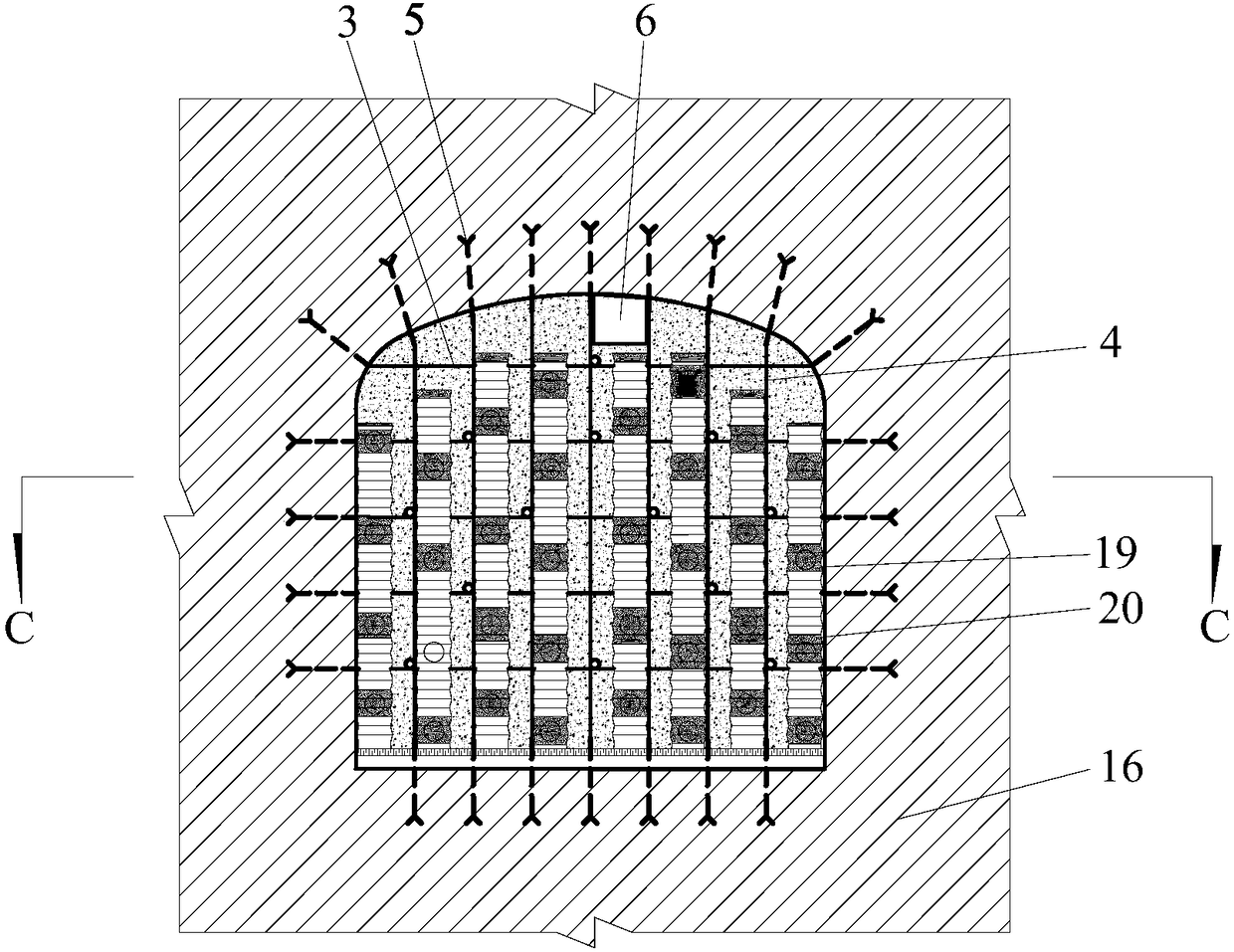

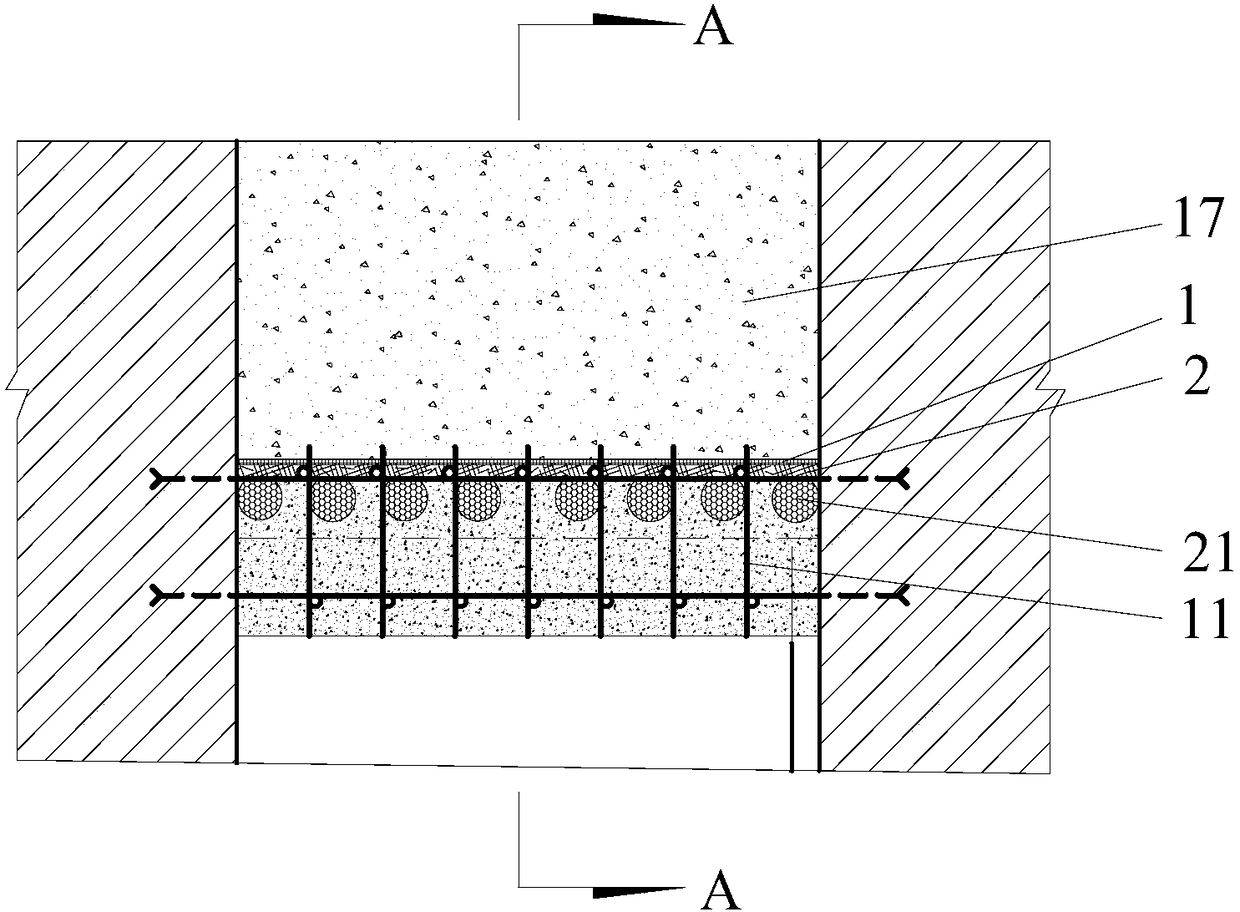

[0022] like figure 1 The permeable reaction filling retaining wall for the in-situ treatment of downhole tailings water is a kind of flexible and airtight water filter retaining wall, the retaining wall skeleton is composed of the inner layer steel skeleton (including the inner layer anchor rod 5, the inner layer transverse reinforcement 3, the inner layer Layer longitudinal reinforcement 4) and outer layer reinforcement skeleton (comprising outer layer anchor rod 7, outer layer transverse reinforcement 9, outer layer longitudinal reinforcement 8), and steel bar 11 are formed. The rest includes metal mesh 1 , filter material layer 2 , bellows PRB reaction uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com