Detection method for stabilizing broken stone gradation by cement

A cement-stabilized gravel and detection method technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effect of reducing variance, reducing cement residue, and improving repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

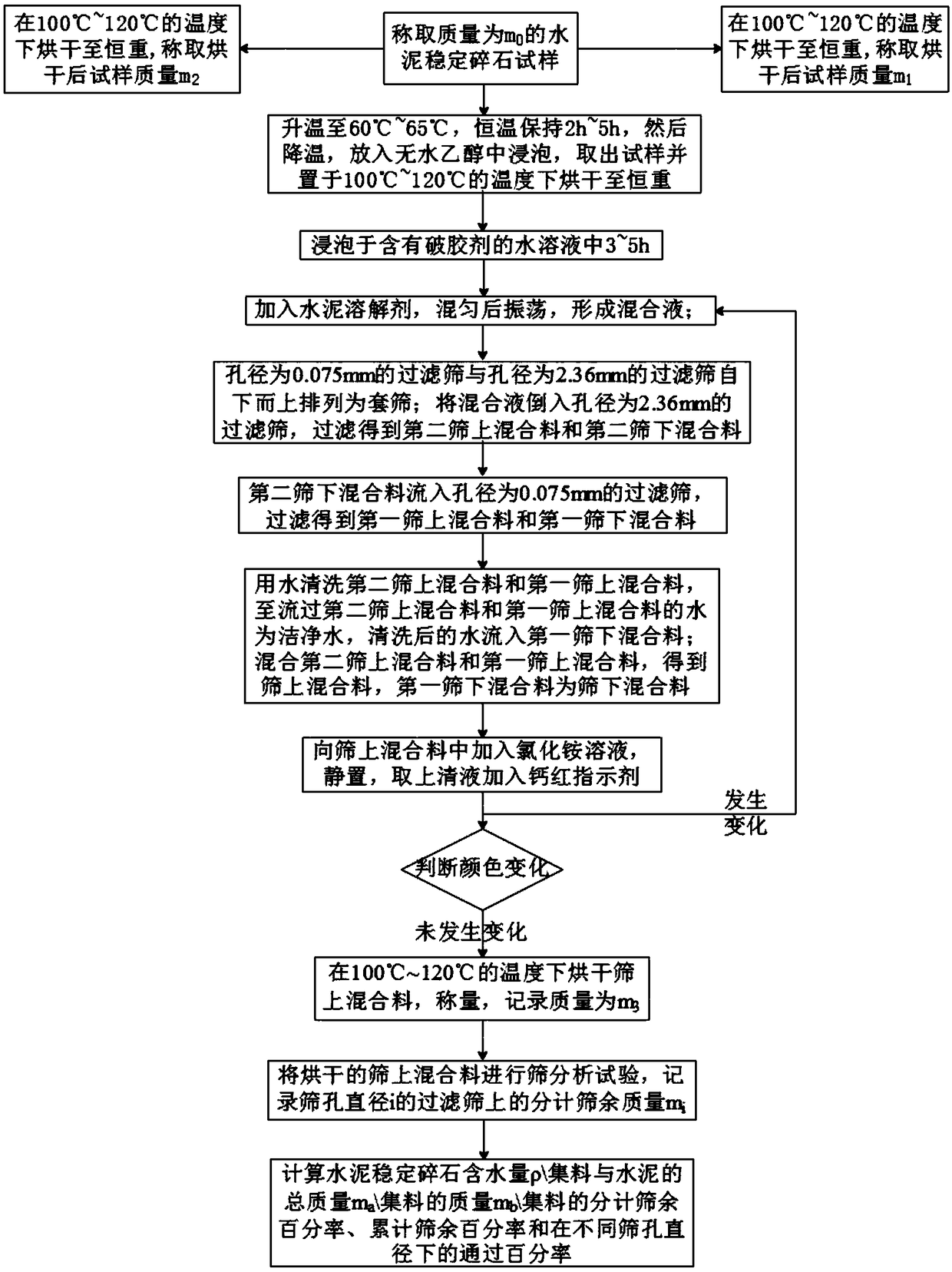

Method used

Image

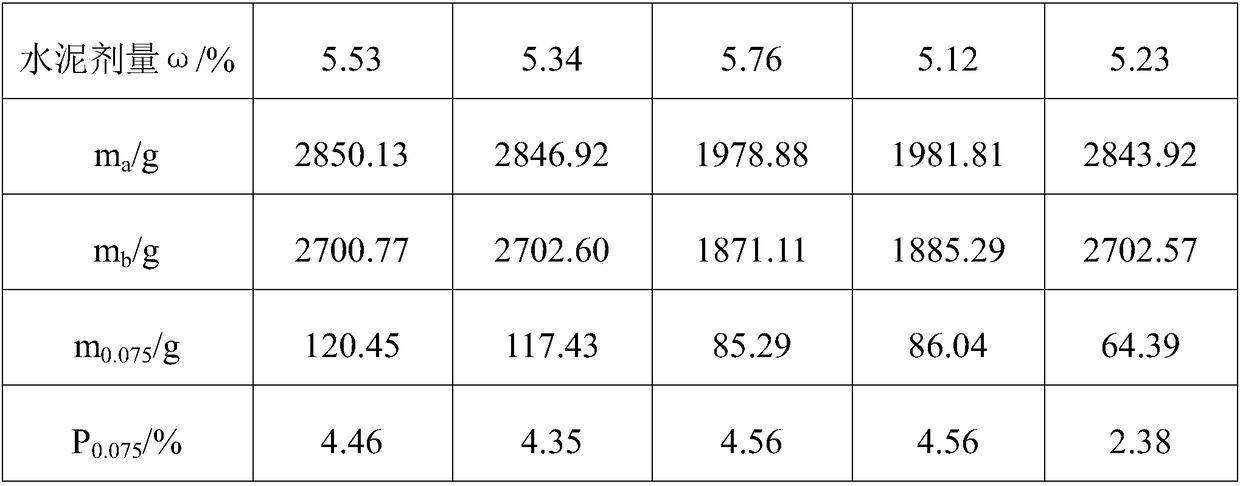

Examples

Embodiment 1

[0048] This embodiment provides a cement dissolving agent, comprising the following components: 15 parts by weight of citric acid, 15 parts by weight of hydrochloric acid, 0.1 part by weight of sodium ethylenediamine tetramethylene phosphonate, and 5 parts by weight of sodium dodecylbenzenesulfonate .

[0049] This embodiment also provides the preparation method of the above-mentioned cement dissolving agent, comprising the steps of: weighing the citric acid, hydrochloric acid, sodium ethylenediamine tetramethylene phosphonate and sodium dodecylbenzenesulfonate of the above-mentioned components and dissolving them in water , mix uniformly, and finally make citric acid containing 15wt%, 15wt% hydrochloric acid, 0.1wt% sodium ethylenediamine tetramethylene phosphonate and 5wt% sodium dodecylbenzenesulfonate and mixed aqueous solution, to obtain cement dissolver.

Embodiment 2

[0051] This embodiment provides a cement dissolving agent, comprising the following components: 20 parts by weight of citric acid, 5 parts by weight of hydrochloric acid, 2 parts by weight of sodium ethylenediamine tetramethylene phosphonate, and 0.1 part by weight of sodium dodecylbenzenesulfonate .

[0052] The present embodiment also provides the preparation method of the above-mentioned cement dissolving agent, comprising the steps of: taking the citric acid, hydrochloric acid, sodium ethylenediamine tetramethylene phosphonate and sodium dodecylbenzenesulfonate of the above-mentioned components and dissolving them in water, Mix evenly, and finally make 20wt% citric acid, 5wt% hydrochloric acid, 2wt% sodium ethylenediamine tetramethylene phosphonate and 0.1wt% sodium dodecylbenzenesulfonate and a mixed aqueous solution to obtain cement Solvent.

Embodiment 3

[0054] This embodiment provides a cement dissolving agent, comprising the following components: 18 parts by weight of citric acid, 12 parts by weight of hydrochloric acid, 0.5 parts by weight of sodium ethylenediamine tetramethylene phosphonate, and 2.5 parts by weight of sodium dodecylbenzenesulfonate .

[0055] The present embodiment also provides the preparation method of the above-mentioned cement dissolving agent, comprising the steps of: taking the citric acid, hydrochloric acid, sodium ethylenediamine tetramethylene phosphonate and sodium dodecylbenzenesulfonate of the above-mentioned components and dissolving them in water, Mix evenly, and finally make citric acid containing 18wt%, 12wt% hydrochloric acid, 0.5wt% sodium ethylenediamine tetramethylene phosphonate and 2.5wt% sodium dodecylbenzenesulfonate and mixed aqueous solution, to obtain cement dissolver.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com