Device and method for preparing composite bipolar plate for fuel cell

A fuel cell and bipolar plate technology, applied in the field of advanced devices, can solve the problems of immature mass production process, complicated pressing process, and restrictions on wide application, and achieve the effects of mass production, production cost reduction, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

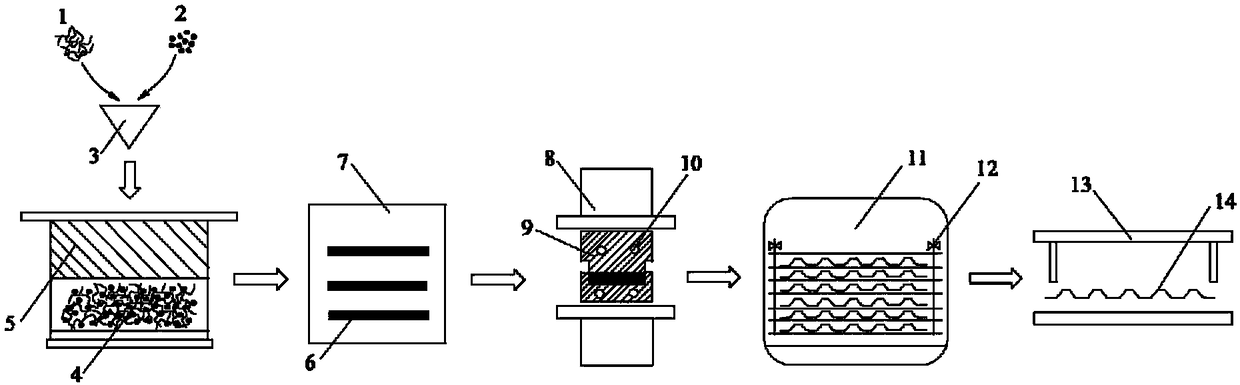

[0022] Such as figure 1 and figure 2 As shown, a device for preparing composite bipolar plates for fuel cells includes a powder mixer 3, a pre-compression mold 5, an oven 7, a mold, a pressure vessel 11 and a knife mold 13, and the powder raw materials are mixed in the powder mixer 3 , the powder raw materials include expanded graphite 1 and polyimide powder 2 .

[0023] Wherein, the pre-compression mold 5 is a steel mold.

[0024] The mold includes a hydraulic press 8, a mold with runners 9 and a cooling device 10, the hydraulic press 8 is connected to the mold with runners 9, and the cooling device 10 is arranged in the mold with runners 9. After the panel 6 is dried in an oven, it is placed in the mold with runners 9, and the mold with runners 9 is driven by the hydraulic press 8 to form the runners.

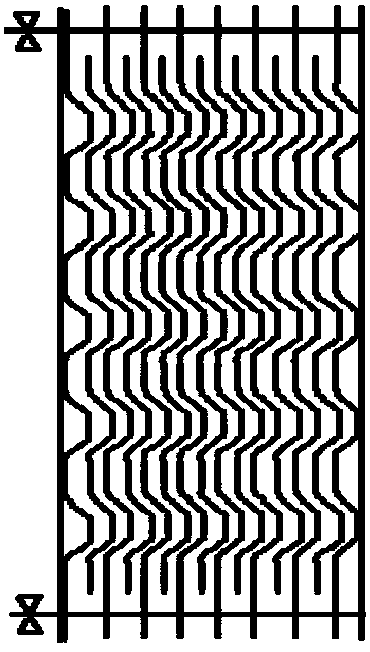

[0025] The pressure vessel 11 includes a sealed cavity, and fixing fixtures 12 arranged on both sides of the sealed cavity, plates with flow channels molded in multiple m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com