A method for preparing bismuth-doped nano-titanium dioxide photocatalyst

A nano-titanium dioxide and photocatalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., to achieve the effect of cheap raw material costs, multiple transfer channels, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

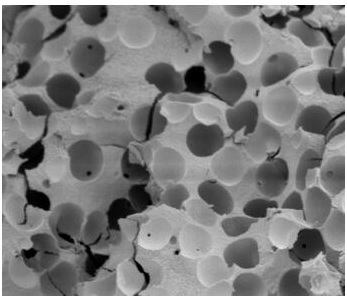

Image

Examples

Embodiment 1

[0027] At room temperature, transfer 1.5 ml of tetrabutyl titanate and 9 ml of absolute ethanol to beaker A with a pipette, and stir evenly with a magnetic stirrer. Take another beaker B, use a pipette to measure 10 ml of absolute ethanol, 1 ml of glacial acetic acid and 3 ml of deionized water into beaker B, and mix evenly with a magnetic stirrer. Then transfer 85 mg of bismuth nitrate pentahydrate to beaker B with an electronic balance, and stir it evenly with a magnetic stirrer. Slowly pour the mixture in beaker A into beaker B under magnetic stirring. After the whole mixture was continuously stirred by magnetic force for 40 minutes, it was transferred to a reaction kettle and left at 65° C. for 10 hours to form a sol-gel. Take out the above-mentioned generated sol-gel and put it into a beaker, under vigorous stirring, weigh 350 mg of polyethylene balls into the beaker. After stirring with a magnetic stirrer for 40 minutes, it was transferred to a reaction kettle and plac...

Embodiment 2

[0029] At room temperature, transfer 1.5 ml of tetrabutyl titanate and 9 ml of absolute ethanol to beaker A with a pipette, and stir evenly with a magnetic stirrer. Take another beaker B, transfer 10 ml of absolute ethanol, 1 ml of glacial acetic acid and 3 ml of deionized water into beaker B with a pipette, and mix evenly with a magnetic stirrer. Slowly pour the mixture in beaker A into beaker B under magnetic stirring. After continuing magnetic stirring for 30 minutes, the entire mixed solution was transferred to a reaction kettle, and left at 65° C. for 10 hours to form a sol-gel. Take out the above-mentioned generated sol-gel and put it into a beaker, under vigorous stirring, weigh 350 mg of polyethylene balls into the beaker. After stirring with a magnetic stirrer for 40 minutes, it was transferred to a reaction kettle and placed at 80° C. for 7 hours to form a gel. Finally, the gel prepared with polyethylene spheres as a template was placed in a muffle furnace and calc...

Embodiment 3

[0031]At room temperature, transfer 1.5 ml of tetrabutyl titanate and 9 ml of absolute ethanol to beaker A with a pipette, and stir evenly with a magnetic stirrer. Take another beaker B, use a pipette to measure 10 ml of absolute ethanol, 1 ml of glacial acetic acid and 3 ml of deionized water into beaker B, and mix evenly with a magnetic stirrer. Then weigh 43 mg of bismuth nitrate pentahydrate with an electronic balance and transfer it to the beaker B, and stir it evenly with a magnetic stirrer. Slowly pour the mixture in beaker A into beaker B under magnetic stirring. After continuing magnetic stirring for 30 minutes, the entire mixed solution was transferred to a reaction kettle, and left at 65° C. for 10 hours to form a sol-gel. Take out the above-mentioned generated sol-gel and put it into a beaker, under vigorous stirring, weigh 350 mg of polyethylene balls into the beaker. After stirring with a magnetic stirrer for 40 minutes, it was transferred to a reaction kettle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com