Manual arc welder heat melting soldering material

A manual arc welding and hot-melt welding technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of uneven bulge or welding ring, brittle welding material, etc., to achieve weldability Good performance, high welding quality, uniform and smooth welding effect

Inactive Publication Date: 2018-10-02

TIANJIN HONGHAOYUAN TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, hot-melt welding is easy to make the welding material brittle, and the tensile stress parameters of the metal material may also cause fusion tumors or uneven welding rings.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0013]

Embodiment 2

[0015]

Embodiment 3

[0017]

[0018]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

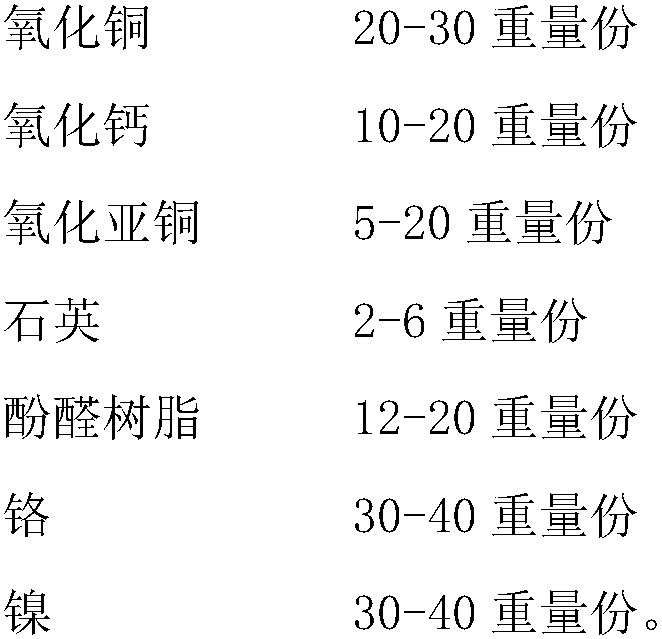

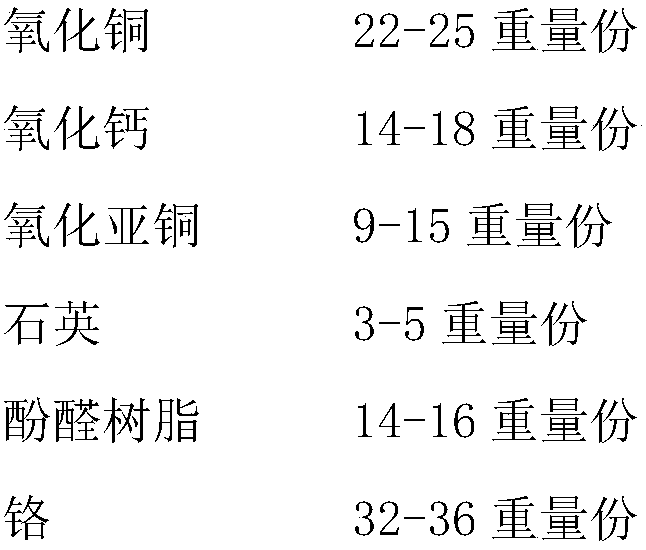

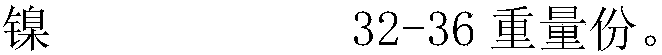

Login to View More Abstract

The invention provides a manual arc welder heat melting soldering material, formed by copper oxide, calcium oxide, cuprous oxide, quartz, phenolic resin, chrome, and nickel. The soldering material isgood in weldability, welding is uniform and smooth, and welding quality is high, and the soldering material has no harm on environment. The soldering material is suitable for a manual arc welder, andwelding quality is good. The soldering material is good in mechanical property, and crack and peeling would not occur. The soldering material has good corrosion resistance, and adding of the calcium oxide and the quartz synergistically increases the corrosion resistance, and service life of a weld assembly is prolonged.

Description

Technical field [0001] The invention relates to the technical field of welding materials, and more specifically to a manual arc welding machine hot-melt welding material. Background technique [0002] Hot melt welding is the use of the reaction between metal compounds to generate high temperature, through the overheated molten metal, direct or indirect heating work, a certain shape and size are formed in the cavity of a special graphite abrasive tool, and a welded joint that meets the process requirements . When welding, the ends of the two workpieces to be welded are fixed in the mold in advance, and then the mixture of aluminum powder and iron oxide powder (called thermite) is heated in the crucible to cause a reduction and exothermic reaction. However, hot-melt welding tends to make the welding material brittle, the tensile stress parameters of metal materials, and at the same time, the phenomenon of welding nodules or unevenness of the welding ring may occur. Summary of the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K35/30B23K35/34

CPCB23K35/3033B23K35/30B23K35/34

Inventor 王少宏

Owner TIANJIN HONGHAOYUAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com