Preparation method of silica aerogel

A silica and aerogel technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problem that the distribution state is not easy to control, the group distribution is irregular, and it is difficult to obtain a monolithic bulk aerogel and other problems, to achieve the effect of reducing cost and operation risk, simple equipment and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of silica airgel, comprising the following steps:

[0034] 1)SiO2 2 Synthesis of Wet Gels:

[0035] a) According to the molar ratio of 1:0.3:(4~14):(6~16), add ethyl orthosilicate, methyltriethoxysilane, absolute ethanol and ultrasonic water into the beaker, add Hydrochloric acid, adjust the pH value to 2.5-3, and keep stirring in the water bath magnetic stirrer for 30-60 minutes to promote the full hydrolysis of the system;

[0036] b) adding a solution concentration of 0.5mol / L ammonia solution, adjusting the pH value to 7-7.5, promoting gel polycondensation, and standing at room temperature to form a gel;

[0037] 2) Aging and modification

[0038] a) Put the gel in an absolute ethanol solution at a temperature of 55-60° C. and let it age for 24-48 hours;

[0039] b) After aging, place the aged gel in a surface modification solution mixed with trimethylchlorosilane, absolute ethanol and n-hexane at a volume ratio of 1:1:8 for modification, an...

Embodiment 1

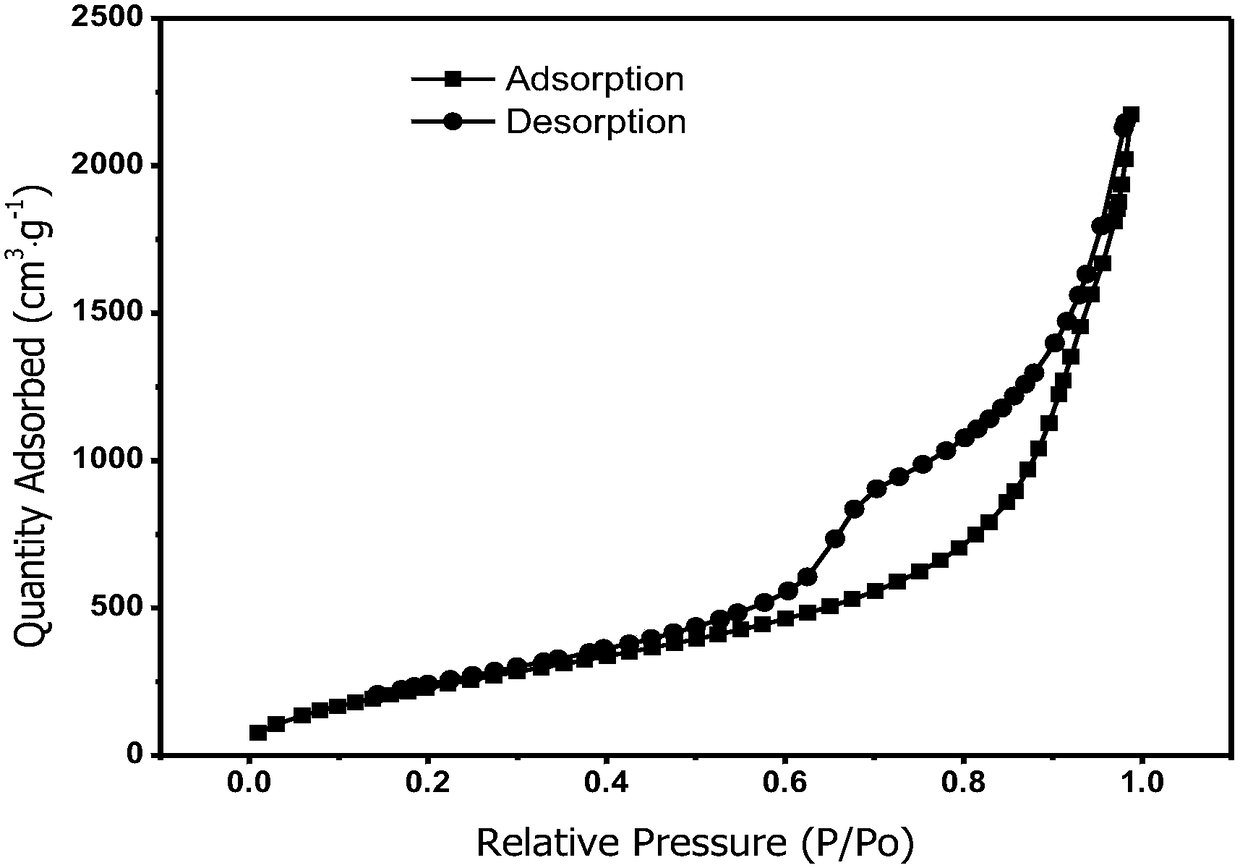

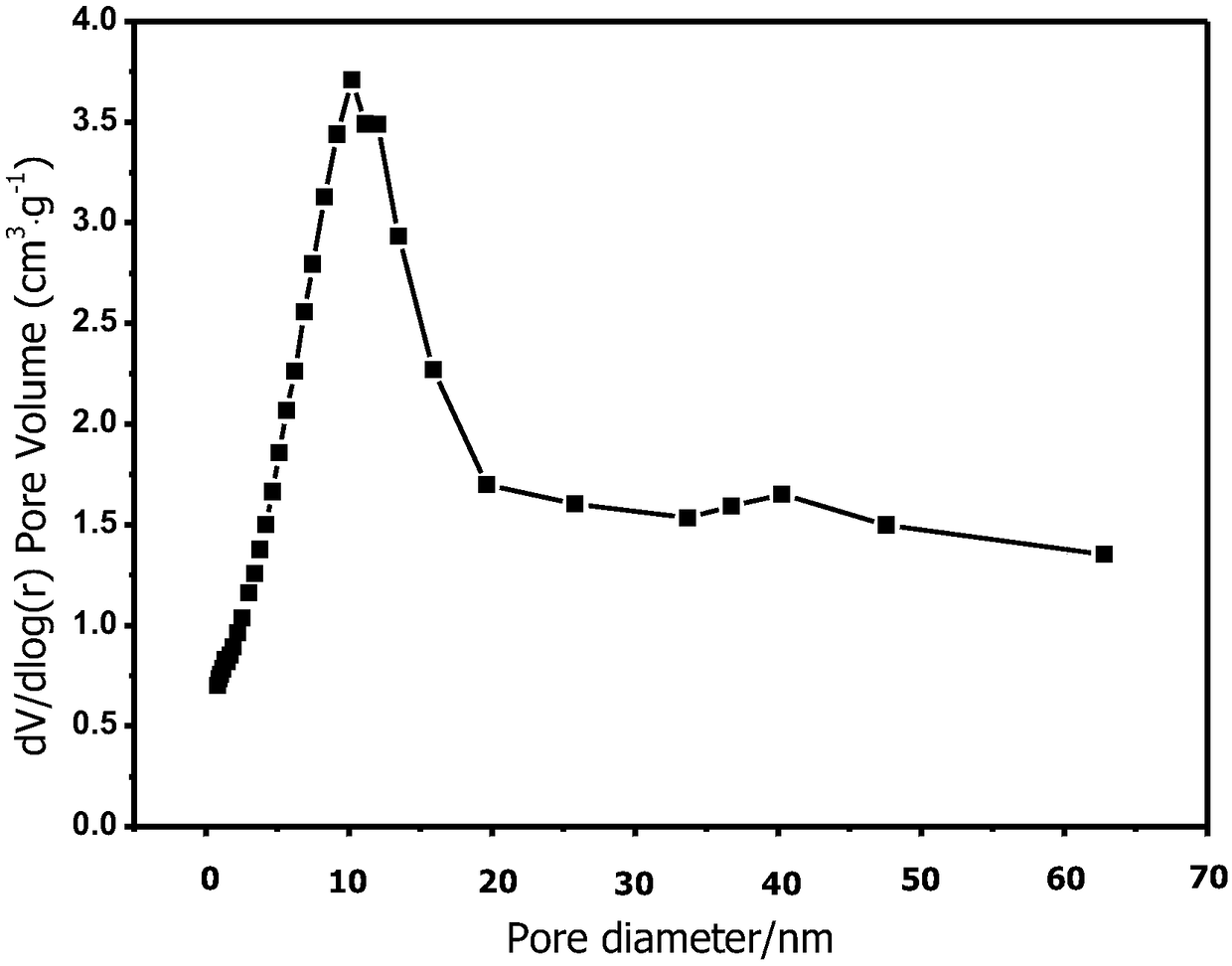

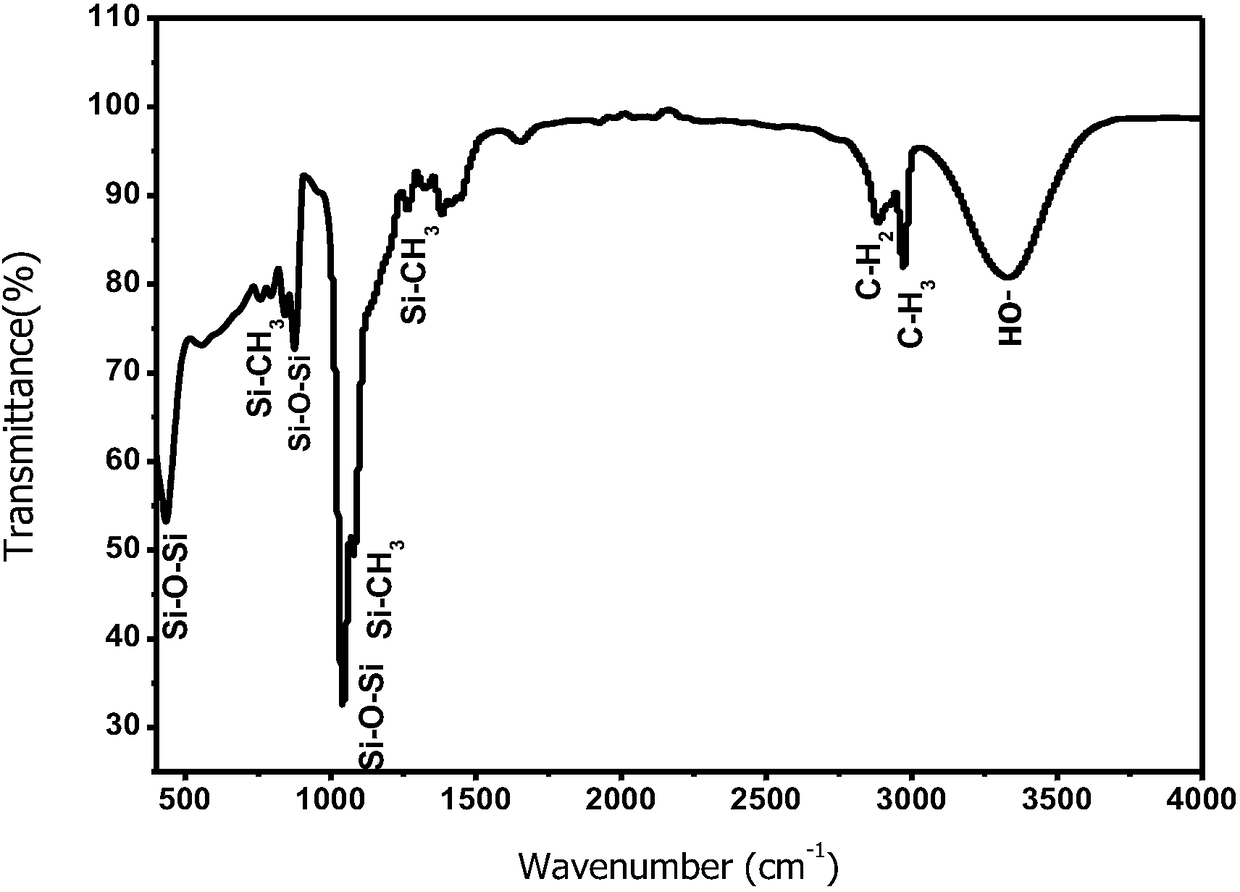

[0044] According to the raw materials according to the molar ratio of ethyl orthosilicate: methyltriethoxysilane: absolute ethanol: ultrasonic water = 1:0.3:6:14, 15.627g of TEOS, 4.011g of MTES, 20.73g of Mix water ethanol and 18.6g of ultrasonic water into the beaker, place it in a water bath environment at 25°C and stir. After 30 minutes, stir evenly and dropwise add hydrochloric acid solution to adjust the pH value, so that the pH value of the solution is about 2.5; after continuous stirring for 30 minutes, then Add a certain amount of ammonia solution with a concentration of 0.5mol / L to make the final pH of the system around 7.5, and let it stand to obtain SiO 2 gel. After the gel is formed, soak the gel in absolute ethanol solution for aging, the aging temperature is 55°C, and the aging time is 48h; Modified in silane (TMCS) / absolute ethanol (EtOH) / n-Hexane (n-Hexane) surface modification solution, soaked under sealed conditions for 48h. After the modification, the sam...

Embodiment 2

[0047] According to the raw material molar ratio of ethyl orthosilicate: methyltriethoxysilane: absolute ethanol: ultrasonic water = 1:0.3:4:16, 15.627g of TEOS, 4.011g of MTES, 13.87g of anhydrous Mix ethanol and 22.24g of ultrasonic water into the beaker, place it in a water bath environment at 25°C and stir it. After 35 minutes, stir evenly and add hydrochloric acid solution dropwise to adjust the pH value so that the pH value of the solution is about 3; after continuous stirring for 35 minutes, then Add a certain amount of ammonia solution with a concentration of 0.5mol / L to make the final pH of the system around 7, and let it stand to obtain SiO 2 gel. After the gel is formed, soak the gel in absolute ethanol solution for aging, the aging temperature is 60°C, and the aging time is 24h; after aging, place the gel in trimethyl chloride with a volume ratio of 1:1:8 Modified in silane (TMCS) / absolute ethanol (EtOH) / n-Hexane (n-Hexane) surface modification solution, soaked un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com