Wastewater concentrate fluidizing, crystallizing, and drying system and method of hot flue gas pressure variable discharge

A waste water concentration and drying system technology, applied in chemical instruments and methods, heating water/sewage treatment, water/sewage treatment, etc., can solve problems such as a large amount of steam, reduced dust removal efficiency, atomization nozzle and flue wear, and achieves Increased heat and mass transfer area, high heat and mass transfer efficiency, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The substantive content of the present invention will be described in detail below in conjunction with the embodiments, but the protection scope of the present invention is not limited thereto. The experimental operations not described in detail in the experiment are routine experimental operations well known to those skilled in the art.

[0045] This embodiment takes desulfurization wastewater concentrate as an example.

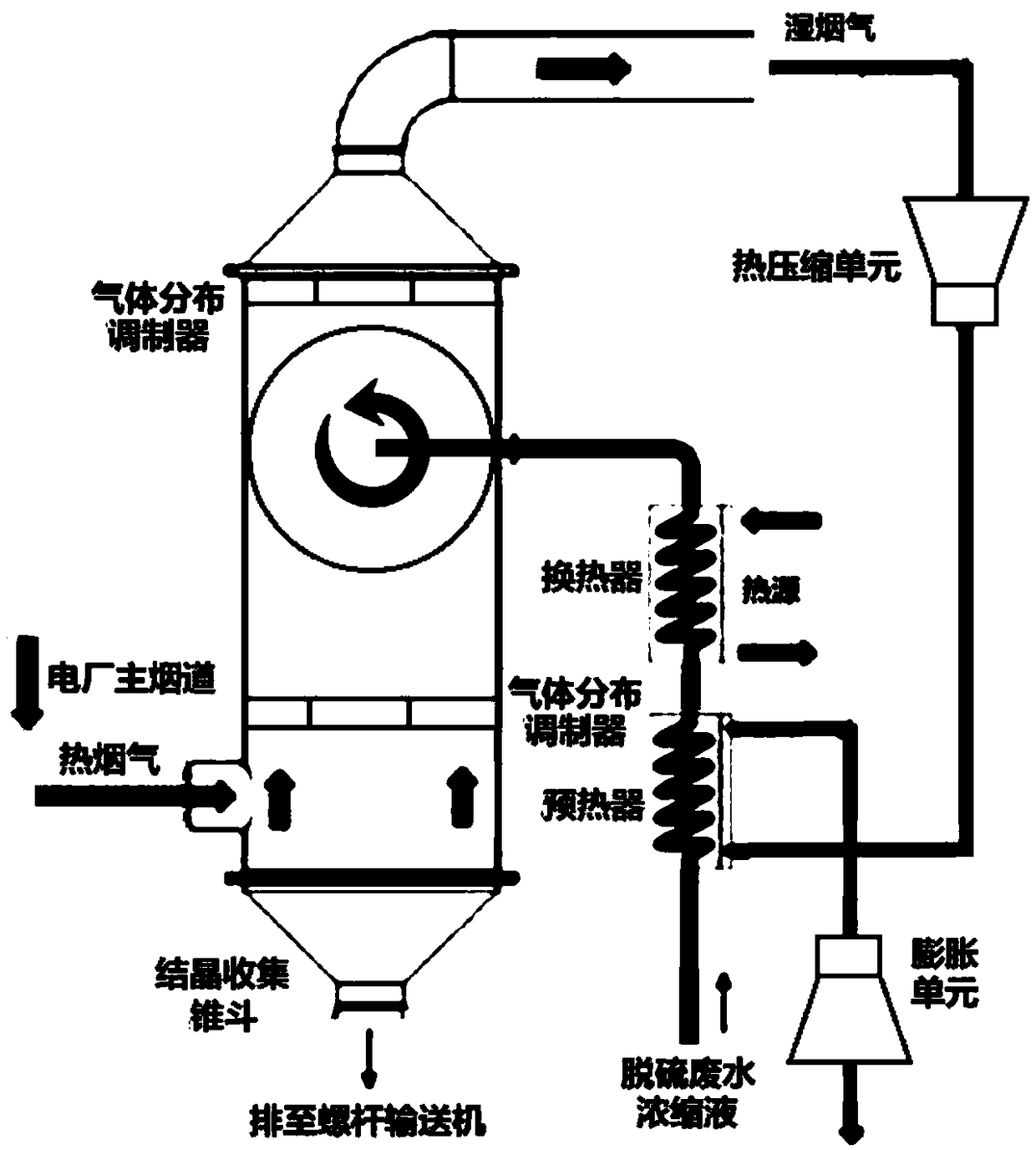

[0046] like figure 1 A fluidized crystallization drying system for thermal desulfurization wastewater concentrated liquid discharged with hot flue gas variable pressure is shown, including a flue gas inlet unit, a desulfurized wastewater concentrated liquid inlet unit, a fluidized crystallization drying tower, and a desulfurized wastewater concentrated liquid heating unit , and flue gas thermal compression unit and expansion unit;

[0047] The lower part of the fluidized crystallization drying tower is provided with an air inlet, the bottom is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com