Production method of water-soluble silicon-potassium fertilizer

A production method and water-soluble technology, applied in potash fertilizers, inorganic fertilizers, fertilization devices, etc., can solve the problems of poor discharge of waste acid, serious waste of raw materials, long production cycle, etc., to achieve low production costs, save costs, and reduce emissions Effects of Pollution Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

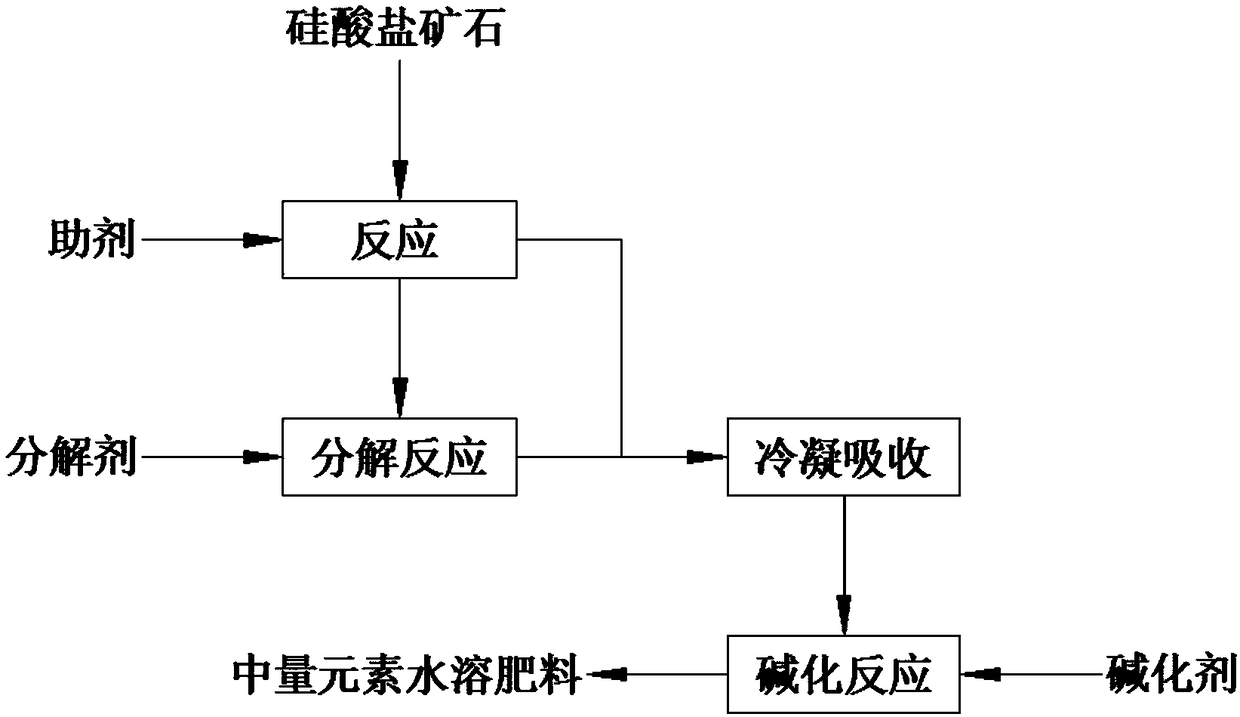

[0029] A kind of production method of water-soluble silicon-potassium fertilizer, it comprises the following steps:

[0030] (1) Reaction: Pulverize the silicate ore to 80 mesh with a mass percentage of 20% fluosilicic acid according to the mass volume of 1t: 2m 3 The proportions were mixed, placed in a reaction kettle at 90°C, and heated for 1 hour to obtain solid 1 and gas 1;

[0031] (2) Decomposition: the solid 1 and the sulfuric acid with a mass percentage of 50% are 1t according to the mass volume: 0.1m 3 Mix evenly, react in a decomposition kettle at 100°C for 1 hour to obtain solid 2 and gas 2;

[0032] (3) Absorption: Gas 1 and gas 2 are recovered through a heat exchanger lined with graphite, and after recovery, solid-liquid separation is carried out through a filter press with a washing device to obtain solid 3 and liquid 1, and liquid 1 is set aside;

[0033] (4) Alkalinization: the solid 3 and 10% potassium hydroxide by mass percentage are 1t: 1m according to the...

Embodiment 2

[0035] A kind of production method of water-soluble silicon-potassium fertilizer, it comprises the following steps:

[0036] (1) Reaction: Pulverize the silicate ore to 150 mesh with a mass percentage of 45% fluosilicic acid according to the mass volume of 1t: 6m 3 The proportions were mixed, placed in a reaction kettle at 100°C, and heated for 3 hours to obtain solid 1 and gas 1;

[0037] (2) Decomposition: the solid 1 and the sulfuric acid with a mass percentage of 98% are 1t: 1m according to the mass volume 3 Mix the proportions evenly, and react for 3 hours at 250°C in a decomposition kettle to obtain solid 2 and gas 2;

[0038] (3) Absorption: Gas 1 and gas 2 are recovered through a Teflon-lined heat exchanger, and after recovery, solid-liquid separation is carried out through a filter press with a washing device to obtain solid 3 and liquid 1, and liquid 1 is set aside;

[0039] (4) Alkalinization: the solid 3 and potassium hydroxide with a mass percentage of 30% are 1...

Embodiment 3

[0041] A kind of production method of water-soluble silicon-potassium fertilizer, it comprises the following steps:

[0042] (1) Reaction: crush the silicate ore to 100 mesh and the mass percentage is 35% fluosilicic acid according to the mass volume of 1t: 4m 3 The proportions were mixed, placed in a reaction kettle at 95°C, and heated for 2 hours to obtain solid 1 and gas 1;

[0043] (2) Decomposition: the solid 1 and the sulfuric acid with a mass percentage of 70% are 1t according to the mass volume: 0.5m 3 Mix evenly, react in a decomposition kettle at 150°C for 2 hours to obtain solid 2 and gas 2;

[0044] (3) Absorption: Gas 1 and gas 2 are recovered through a heat exchanger lined with EPDM rubber for corrosion resistance, and after recovery, solid-liquid separation is carried out through a filter press with a washing device to obtain solid 3 and liquid 1, liquid 1 for use;

[0045] (4) Alkalinization: the solid 3 and potassium hydroxide with a mass percentage of 20% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com