Method for resource utilization of agricultural wastes

A technology for recycling agricultural waste, which is applied in the field of resource utilization of agricultural waste, can solve the problems of blocked pipelines, low fertilizer efficiency, death, etc., and achieve the effect of reducing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

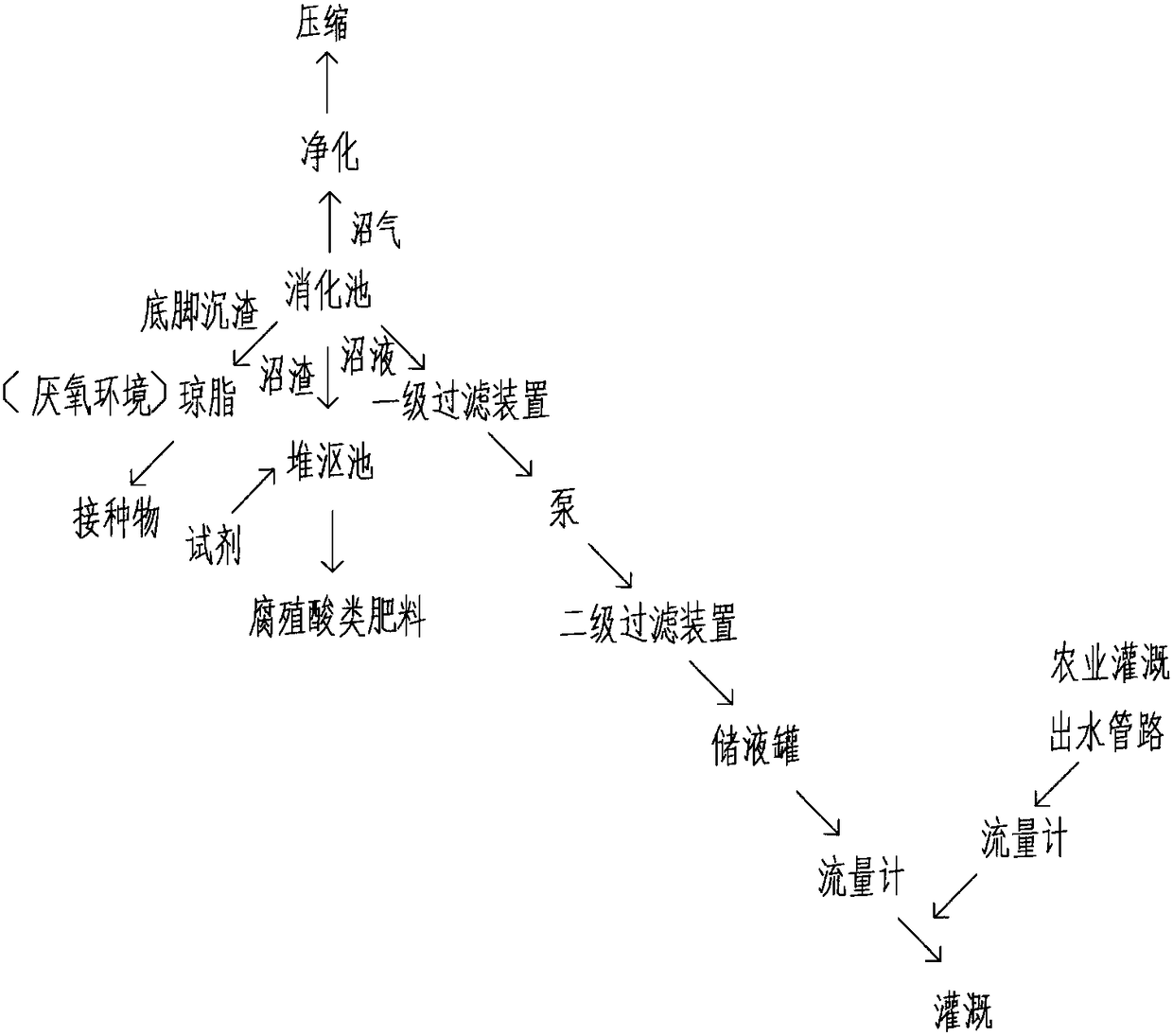

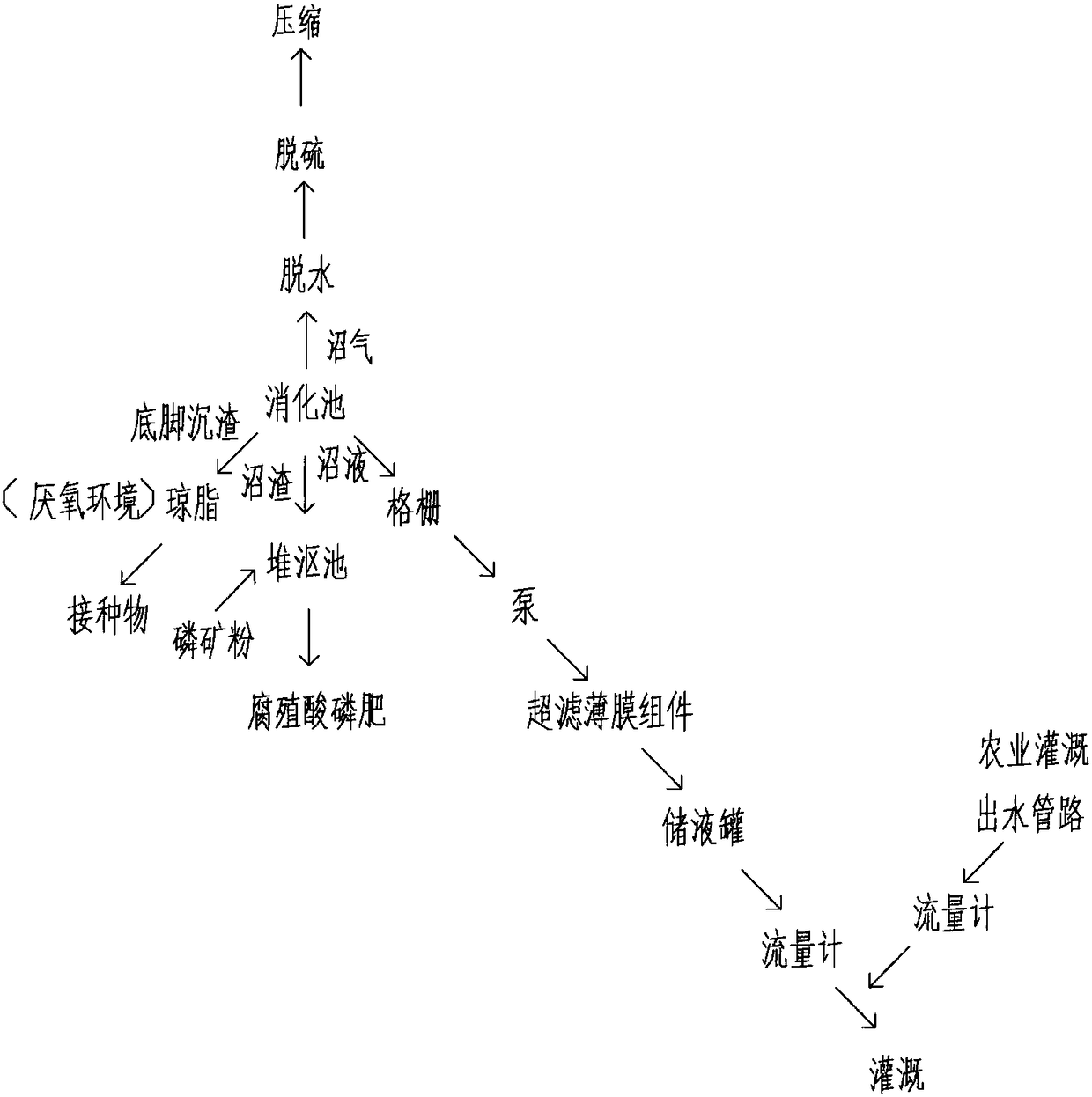

[0027] Such as figure 2 As shown, the agricultural waste is put into the digester for fermentation, and the generated biogas is dehydrated by the dehydration device, then enters the desulfurization tower of the two-part hanging frame desulfurization tower, is compressed by the compressor, and is ready for use; The biogas slurry in the digester is pumped into the liquid storage tank, and the biogas slurry is filtered through the grille between the digester and the pump. The grille is located at the outlet of the digester at an angle of 60 degrees to the ground; After being filtered by the ultrafiltration membrane module, it enters the liquid storage tank; the outlet pipe of the liquid storage tank is connected with the outlet pipe of agricultural irrigation, and is used for coupled irrigation of crops; the outlet pipe of the liquid storage tank is provided with a water flow meter; A water flow meter is installed on the outlet pipeline of the agricultural irrigation described a...

Embodiment 2

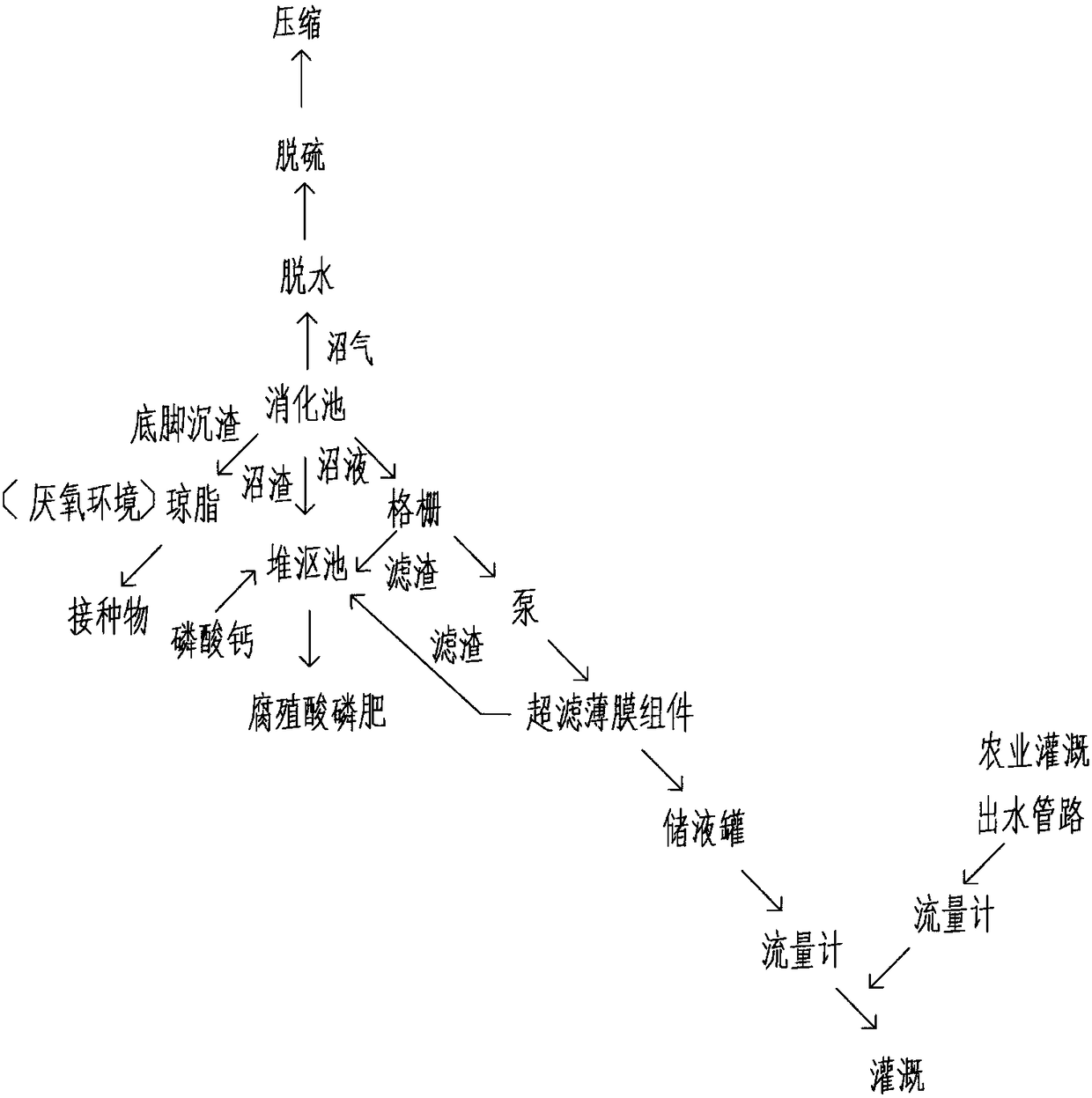

[0029] Such as image 3 As shown, the agricultural waste is put into the digester for fermentation, and the generated biogas is dehydrated by the dehydration device, then enters the central tubular desulfurization tower for desulfurization, is compressed by the compressor, and is ready for use; after the fermentation is completed, the digester is pumped. The biogas slurry is pumped into the liquid storage tank, and the biogas slurry is filtered through the grille between the digester and the pump. The grille is located at the outlet of the digester and has an angle of 60 degrees with the ground; After the filter membrane module is filtered, it enters the liquid storage tank; when the grid and the ultrafiltration membrane module are backwashed, the filter residue generated is retained and placed in the subsequent stacking retting tank; the outlet pipe of the liquid storage tank and the outlet pipe of agricultural irrigation connected to each other for coupled irrigation of crop...

Embodiment 3

[0031] Such as Figure 4As shown, the agricultural waste is put into the digester for fermentation, and the generated biogas is dehydrated by the dehydration device, then enters the central tubular desulfurization tower for desulfurization, is compressed by the compressor, and is ready for use; after the fermentation is completed, the digester is pumped. The biogas slurry is pumped into the liquid storage tank, and the biogas slurry is filtered through the grille between the digester and the pump. The grille is located at the outlet of the digester and has an angle of 60 degrees with the ground; After the filter membrane module is filtered, it enters the liquid storage tank; when the grid and the ultrafiltration membrane module are backwashed, the filter residue generated is retained and placed in the subsequent stacking retting tank; the outlet pipe of the liquid storage tank and the outlet pipe of agricultural irrigation connected to each other for coupled irrigation of crop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com