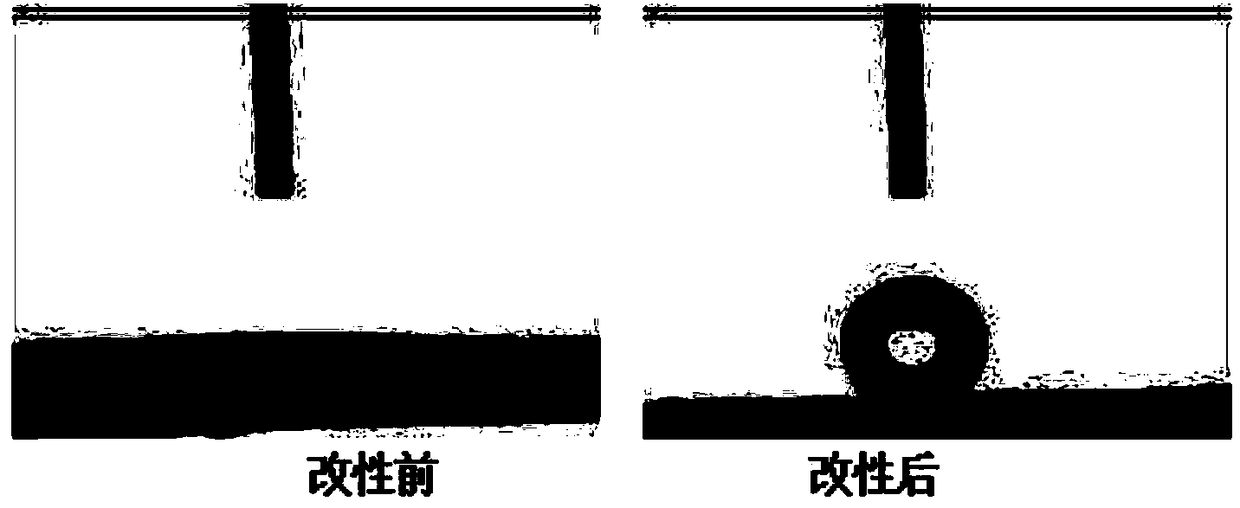

Surface hydrophobic modification method of nano cellulose

A nano-cellulose and hydrophobic modification technology, applied in the field of polymer materials, can solve the problems of lengthy solvent exchange process, complicated and lengthy steps, few steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for surface hydrophobic modification of nanocellulose, comprising the steps of:

[0027] (1) adding nanocellulose to distilled water, mixing uniformly to obtain a nanocellulose suspension with a concentration of 2wt%;

[0028] (2) Add DL-lactic acid solution with a mass fraction of 85% in the above-mentioned CNF suspension, the weight of DL-lactic acid solution is 10 times of the weight of the CNF suspension, the ultrasonic dispersion is uniform, the ultrasonic time is 2min, and the frequency of ultrasonic dispersion is 20KHz;

[0029] (3) Put the uniformly dispersed mixed solution in a three-necked flask, add the metal oxide catalyst tin protochloride (the amount is 5 / 10,000 of the DL-lactic acid solution), and then place the three-necked flask in a constant temperature oil bath at 180°C distilled in

[0030] (4) In step (3), when 99% of the water in the CNF suspension is distilled out, add the esterification modifier alkenyl succinic acid (200ml alkenyl suc...

Embodiment 2

[0034] A method for surface hydrophobic modification of nanocellulose, comprising the steps of:

[0035] (1) adding nanocellulose to distilled water, mixing uniformly to obtain a nanocellulose suspension with a concentration of 5wt%;

[0036] (2) Add DL-lactic acid syrup solution with a mass fraction of 85% to the above CNF suspension, the weight of the DL-lactic acid solution is 10 times the weight of the CNF suspension, the ultrasonic dispersion is uniform, the ultrasonic time is 5min, and the frequency of ultrasonic dispersion is 20KHz;

[0037] (3) Put the uniformly dispersed mixed solution in a three-necked flask, add the metal oxide catalyst zinc acetate dihydrate (the amount is 5 / 10,000 of the DL-lactic acid solution), and then place the three-necked flask in a constant temperature oil bath at 160°C distilled in

[0038] (4) After 90% of the water in the CNF suspension is distilled out, the esterification modifier glutaric acid (add 250ml glutaric acid per 1g of nanoc...

Embodiment 3

[0042] A method for surface hydrophobic modification of nanocellulose, comprising the steps of:

[0043] (1) adding nanocellulose to distilled water, mixing uniformly to obtain a nanocellulose suspension with a concentration of 6wt%;

[0044] (2) Add DL-lactic acid solution with a mass fraction of 85% in the above-mentioned CNF suspension, the weight of DL-lactic acid solution is 10 times of the weight of the CNF suspension, the ultrasonic dispersion is uniform, the ultrasonic time is 8min, and the frequency of ultrasonic dispersion is 20KHz.

[0045] (3) Put the uniformly dispersed mixed solution in a three-necked flask, add metal oxide catalyst zinc acetate dihydrate (the amount is 5 / 10,000 of the DL-lactic acid syrup solution), and then place the three-necked flask in a constant temperature oil bath at 170°C distillation in a pot;

[0046] (4) After 85% of the water in the CNF suspension is distilled out, add the esterification modifier linseed oil (add 400ml linseed oil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com