Salted yolk sauce seasoner as well as preparation method thereof

A technology of seasoning and salted egg yolk, which is applied in the field of salted egg yolk sauce seasoning and its preparation, can solve the problems of unfavorable human health and greasy taste, and achieve the effects of excellent embedding effect, smooth taste and bright flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

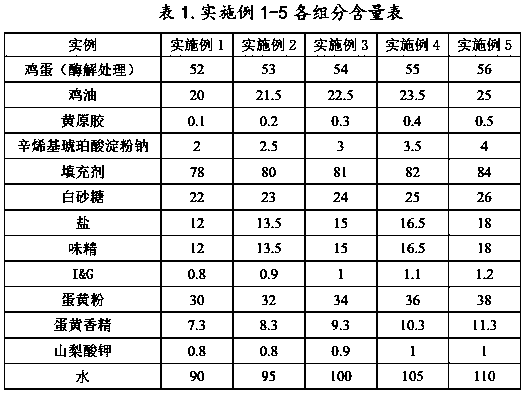

[0059] A kind of salted egg yolk sauce seasoning, by weight, the content of each component is as shown in the following table:

[0060]

[0061] I&G: Taste disodium nucleotide, that is, 50% combination of sodium 5' inosine (IMP, Disodiuminosine 5'-monophosphate) and sodium 5'guanosine (GMP, Disodium guanosine 5'-monophosphate).

[0062] In each of the above examples, the filler is a mixture of distarch phosphate and maltodextrin, wherein the weight ratio of distarch phosphate and maltodextrin is 9:72. The eggs used (enzymolysis treatment) are fresh egg liquid plus water and protease for enzymolysis treatment. The weight ratio of eggs, water and protease during enzymolysis is egg: water: protease = 54:93:0.21, The protease used was a complex protease purchased from Hunan Century Huaxing Bioengineering Co., Ltd. The xanthan gum used can be replaced by gum arabic, gelatin or carrageenan. Potassium sorbate as a preservative can also be replaced by sodium sorbate, benzoic acid...

Embodiment 6

[0064] A preparation method of salted egg yolk sauce seasoning, it comprises the steps,

[0065] Step 1. Enzymatic hydrolysis of eggs: Weigh 52 parts of eggs according to the parts by weight, add water and stir according to the ratio of eggs: water = 54:93 (weight ratio) to obtain diluted egg liquid. Stir the egg liquid at a speed of 200r / min, and heat up to 60°C. Add protease to the egg liquid according to the ratio of egg: protease = 54:0.21 (weight ratio), keep warm at 60°C for 2 hours for enzymolysis, and continuously stir the egg liquid during the reaction. After the reaction, continue to heat up to 85° C. and keep it warm for 30 minutes to inactivate the protease to obtain egg enzymatic hydrolyzate for later use.

[0066] Step 2: Add the egg enzymatic solution obtained in Step 1 into the mixing tank, add 90 parts by weight of water, 20 parts of chicken fat, 0.1 part of xanthan gum, and 2 parts of sodium starch octenyl succinate , 78 parts of filler, 30 parts of egg yol...

Embodiment 7

[0070] A preparation method of salted egg yolk sauce seasoning, it comprises the steps,

[0071] Step 1. Egg enzymatic hydrolysis: Weigh 53 parts of eggs according to the parts by weight, add water and stir according to the ratio of eggs: water = 54:93 (weight ratio) to obtain diluted egg liquid. Stir the egg liquid at a speed of 200r / min, and heat up to 60°C. Add protease to the egg liquid according to the ratio of egg: protease = 54:0.21 (weight ratio), keep warm at 60°C for 2 hours for enzymolysis, and continuously stir the egg liquid during the reaction. After the reaction, continue to heat up to 85° C. and keep it warm for 30 minutes to inactivate the protease to obtain egg enzymatic hydrolyzate for later use.

[0072] Step 2: Add the egg enzymatic solution obtained in Step 1 into the mixing tank, add 95 parts by weight of water, 21.5 parts of chicken fat, 0.2 parts of xanthan gum, and 2.5 parts of sodium starch octenyl succinate , 80 parts of filler, and 32 parts of eg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com