Magnetic response graphene oxide/plant fiber adsorption material and its preparation method and application

A plant fiber and adsorption material technology, applied in the direction of alkali metal oxides/hydroxides, chemical instruments and methods, alkali metal compounds, etc., can solve problems such as inability to meet low-concentration adsorption, low removal rate, and complicated preparation process. Achieve the effects of harsh reaction conditions, improved utilization efficiency, and more preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

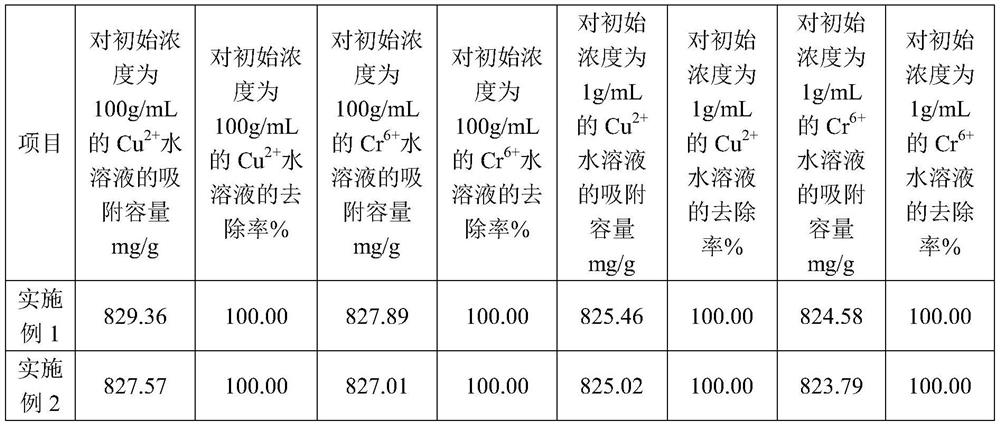

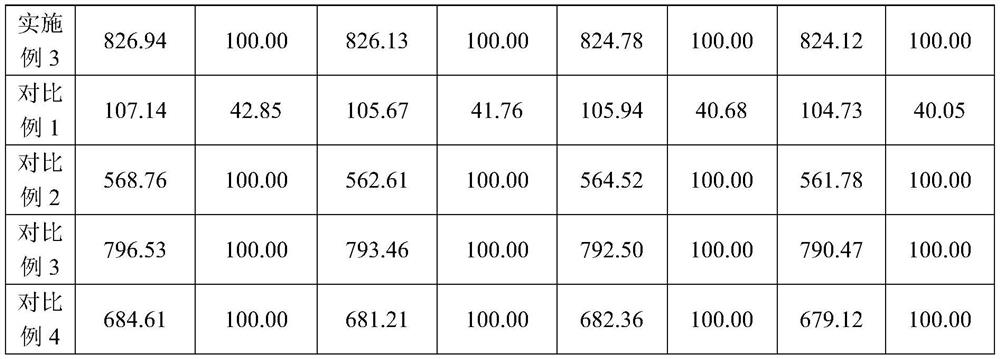

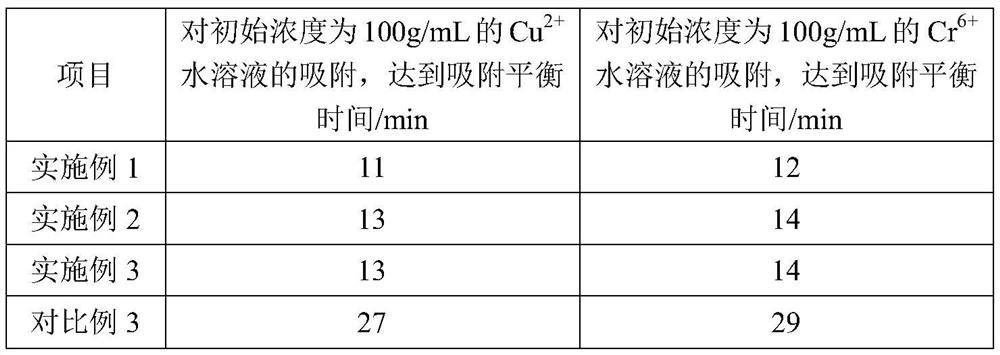

Examples

Embodiment 1

[0035] Example 1 Preparation of Magnetically Responsive Graphene Oxide / Plant Fiber Adsorbent Material

[0036] ① Preparation of xanthanized plant fiber: first weigh 5g of dry bagasse fiber into a 250mL three-necked flask, add 50mL of NaOH solution with a mass fraction of 14%, stir until the bagasse fiber is completely dispersed and evenly, then add 27mL of CS 2 Ethanol solution (volume ratio is 1:8), after reacting for 2h, add 25mL of MgSO with a mass fraction of 10% 4 Solution, react for 1h, filter, and successively use 50mL of MgSO with a mass fraction of 5% 4 solution and 50 mL of ethanol for soaking and washing, and finally washing with deionized water until the filtrate is neutral, and then freeze-drying to constant weight to obtain xanthated bagasse fiber.

[0037] ②Modified ferrofluid Fe 3 o 4 Preparation: Weigh 90g FeCl 3 ·6H 2 O and 48g FeSO 4 ·7H 2 O was added to a 500mL three-necked flask, and 100mL of deionized water was added, stirred in a water bath at 75°...

Embodiment 2

[0041] Example 2 Preparation of Magnetically Responsive Graphene Oxide / Plant Fiber Adsorbent Material

[0042] ① Preparation of xanthanized plant fiber: First weigh 5g of dry sisal fiber into a 250mL three-neck flask, add 45mL of NaOH solution with a mass fraction of 10%, stir until the sisal fiber is completely dispersed and evenly, then add 6mL drop by drop CS 2 Ethanol solution (volume ratio is 1:5), after reacting for 1h, add 20mL of MgSO with a mass fraction of 5% 4 solution, reacted for 0.5h, filtered, followed by 50mL mass fraction of 5% MgSO 4 solution and 50 mL of ethanol for soaking and washing, and finally washing with deionized water until the filtrate is neutral, and then freeze-drying to constant weight to obtain xanthated sisal fiber.

[0043] ②Modified ferrofluid Fe 3 o 4 Preparation: Weigh 90g FeCl 3 ·6H 2 O and 45g FeSO 4 ·7H 2 Add 100 mL of deionized water to a 500 mL three-neck flask, stir in a water bath at 70°C until dissolved, and then quickly ad...

Embodiment 3

[0047] Example 3 Preparation of Magnetically Responsive Graphene Oxide / Plant Fiber Adsorbent Material

[0048] ① Preparation of xanthified plant fiber: first weigh 5g of dry bamboo shoot shell fiber into a 250mL three-neck flask, add 55mL of NaOH solution with a mass fraction of 20%, stir until the bamboo shoot shell fiber is completely dispersed, and then add 55mL of it drop by drop CS 2 Ethanol solution (volume ratio is 1:10), after reacting for 3h, add 30mL mass fraction of 15% (NH4 ) 2 SO 4 solution, reacted for 1.5h, filtered, followed by 50mL mass fraction of 5% (NH 4 ) 2 SO 4 solution and 50 mL of ethanol for soaking and washing, and finally washing with deionized water until the filtrate is neutral, and then freeze-drying to constant weight to obtain xanthified bamboo shoot shell fiber.

[0049] ②Modified ferrofluid Fe 3 o 4 Preparation: Weigh 90g FeCl 3 ·6H 2 O and 50g FeSO 4 ·7H 2 Add 100 mL of deionized water to a 500 mL three-neck flask, stir in a water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com