A kind of carbon dioxide hydrogenation catalyst for producing light olefins and its preparation method and application

A technology of low-carbon olefins and carbon dioxide, applied in the field of carbon dioxide hydrogenation to low-carbon olefins catalysts and its preparation, can solve the problems of low utilization rate, high selectivity of by-product methane, low selectivity of low-carbon olefins, etc., to achieve cheap and simple , uniform and controllable shape, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

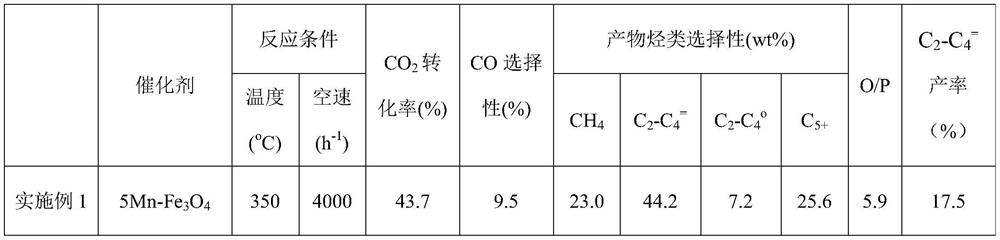

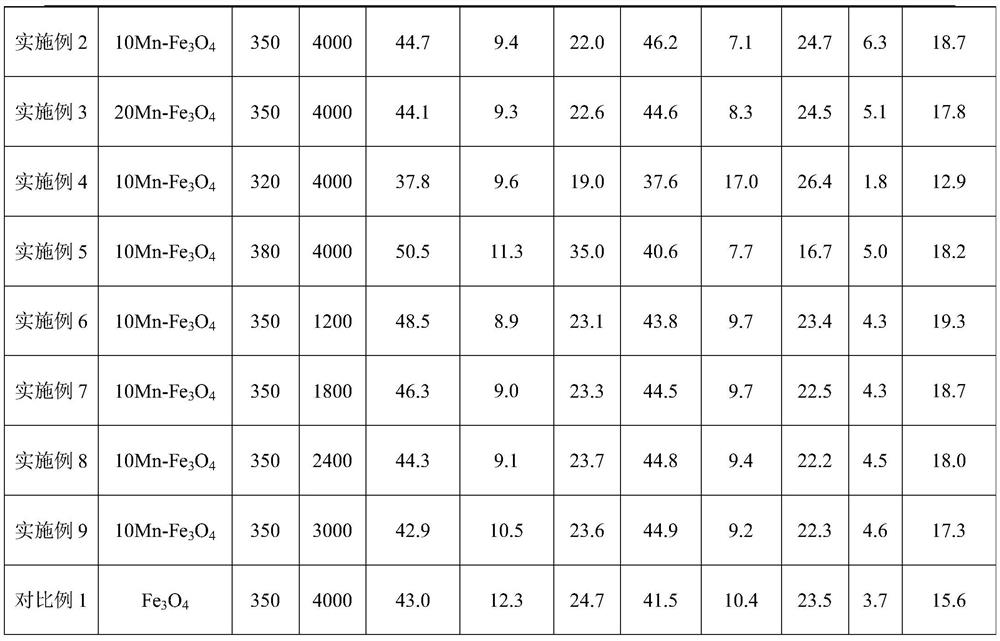

Examples

Embodiment 1

[0030] (1) Catalyst preparation:

[0031] ① Preparation of magnetic Fe with uniform particle size by hydrothermal synthesis 3 o 4 Nanospheres: Dissolve ferric chloride in ethylene glycol, then add sodium acetate, ethylenediamine and polyvinylpyrrolidone, the molar ratio of ferric chloride, sodium acetate and ethylenediamine is: 1:9:15 , the addition of the polyvinylpyrrolidone is 1.23 times of the weight of ferric chloride, and it is stirred until it is completely dissolved; ℃ hydrothermal reaction for 12 hours; after cooling down to room temperature, the obtained product was transferred to a beaker, washed with deionized water and absolute ethanol for 3 times, and then dried at 60 ℃ to obtain Fe 3 o 4 For nanospheres, the particle size is mainly concentrated at 120±12nm.

[0032] ② Fe 3 o 4 The surface of the nanosphere is pretreated: weigh 1g of Fe prepared in step ① 3 o 4 Nanospheres were placed in a glass cup, 5mL of ethylene glycol was added, and ultrasonically di...

Embodiment 2

[0038] The preparation of the catalyst refers to Example 1, the difference is that the concentration of step 3. manganese nitrate solution is 0.92mol / L, and the loading of manganese in the finally prepared catalyst is 10%wt, recorded as 10Mn-Fe 3 o 4 , the rest of the steps are the same as in Example 1.

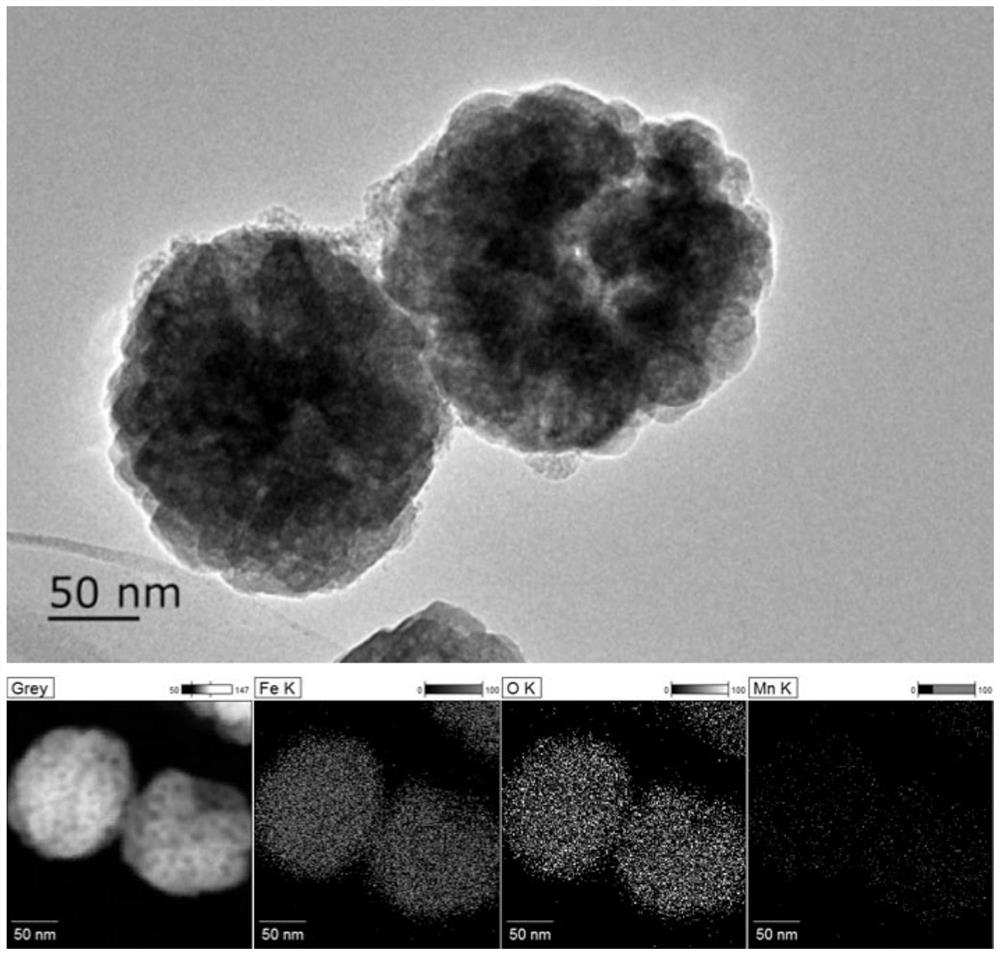

[0039] The 10Mn-Fe that embodiment 2 prepares 3 o 4 The catalyst was scanned by a transmission electron microscope to observe the morphology of the catalyst and the corresponding element distribution. The results are shown in figure 1 shown. Depend on figure 1 It can be seen that the prepared catalyst has a uniform and stable morphology, and the manganese element is evenly distributed in the Fe 3 o 4 microsphere surface.

Embodiment 3

[0041] The preparation of the catalyst refers to Example 1, the difference is that the concentration of step ③ manganese nitrate solution is 1.84mol / L, and the loading of manganese in the finally prepared catalyst is 20%wt, recorded as 20Mn-Fe 3 o 4 , the rest of the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com