A kind of preparation method of chelating agent n,n'-ethylenediamine disuccinic acid sodium salt

A technology of ethylenediamine disuccinate and ethylenediamine, which is applied in the field of preparation of chelating agent N,N'-ethylenediamine disuccinate sodium salt, can solve difficult separation, many by-products, long reaction time, etc. problem, achieve the effect of reducing the reaction time, increasing the adding speed and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

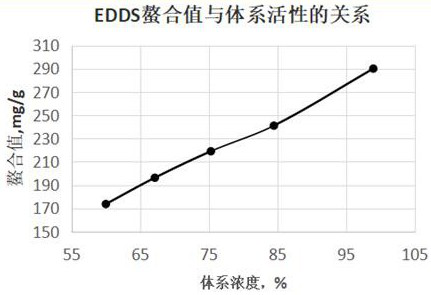

Image

Examples

Embodiment 1

[0032] Preheat the reactor to 60°C, add liquid maleic anhydride to the reactor, start stirring, raise the temperature and control the temperature of the system within the range of 75~77°C, add 30% aqueous sodium hydroxide solution dropwise to adjust the pH of the system to 11 . Add ethylenediamine dropwise to the reaction kettle, increase the pressure of the reaction system to 0.3MPa, raise the temperature to 146°C and keep it under reflux for 4 hours, then lower the temperature and pressure to obtain the finished product of N,N'-ethylenediamine disuccinic acid sodium salt. The yield was 92.2% based on N,N'-ethylenediamine disuccinic acid sodium salt.

Embodiment 2

[0034] The method of increasing the reaction system pressure to 0.3MPa in Example 1 is replaced by raising the reaction system pressure to 0.5MPa. The yield was 90.2% based on N,N'-ethylenediamine disuccinic acid sodium salt.

Embodiment 3

[0036] Preheat the reaction kettle to 55°C, add liquid maleic anhydride to the reaction kettle, start stirring, raise the temperature and control the system temperature within the range of 76~80°C, add 20% aqueous sodium hydroxide solution dropwise to adjust the pH of the system to 10.8 . Add ethylenediamine dropwise to the reaction kettle, raise the pressure of the reaction system to 0.2MPa, raise the temperature to 155°C and keep it under reflux for 4 hours, lower the temperature and reduce the pressure to obtain the finished product of N,N'-ethylenediamine disuccinic acid sodium salt. The yield is 92.3% based on N,N'-ethylenediamine disuccinic acid sodium salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com