Seawater degradation material with adjustable use cycle and degradation cycle and preparation method of seawater degradation material

A technology of degrading materials and degradation cycle, applied in the field of seawater purification, can solve the problems of loss of mechanical properties, high requirements for degradation environment, poor water resistance, etc., and achieve the effect of prolonging the service cycle, simple and controllable process, and overcoming high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

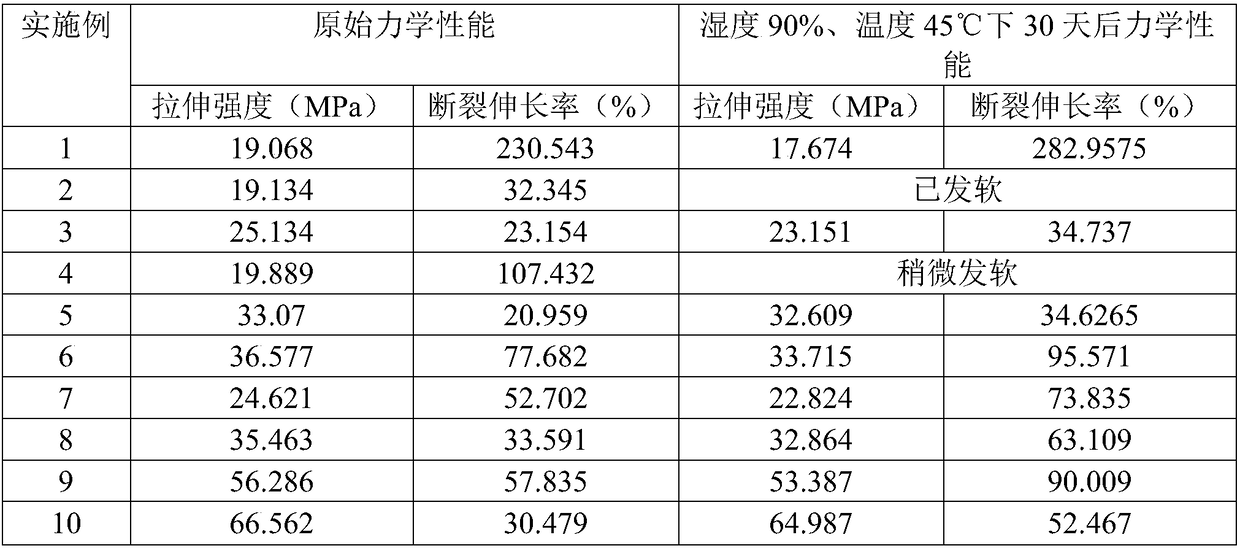

Examples

preparation example Construction

[0051] In addition, the second aspect of the present invention also provides a preparation method of the above-mentioned seawater degradable material with adjustable use period and degradation period, comprising the following steps:

[0052] 1) Polyvinyl alcohol thermoplastic modification:

[0053] It is obtained by mixing polyvinyl alcohol and plasticizer, sealing and plasticizing, and extruding and granulating;

[0054] 2) Preparation of seawater degradable material: The thermoplastic modified polyvinyl alcohol, polyester and compatibilizer are mixed in proportion, extruded and granulated, and injection molded to obtain seawater degradable material with adjustable use cycle and degradation cycle.

[0055] Hereinafter, each step in the synthesis method will be described in detail.

[0056] A possible implementation in step 1) is to add polyvinyl alcohol and plasticizer in a mass ratio of 80:20-90:10 into a high-speed mixer for multiple stirring until fully mixed to obtain a ...

Embodiment 1

[0060] A seawater degradable material with adjustable use period and degradation period is made from the following raw materials in parts by weight:

[0061] Thermoplastic modified 0388 polyvinyl alcohol: 8 parts;

[0062] Polycaprolactone: 90 parts;

[0063] ADR-4380: 2 servings.

[0064] The preparation of the above-mentioned seawater degradable material comprises the following steps:

[0065] 1) Polyvinyl alcohol thermoplastic modification: Add 0388 polyvinyl alcohol and sorbitol in a mass ratio of 80:20 to a high-speed mixer for multiple stirrings, stirring for 1 to 2 minutes each time, until fully mixed to obtain a premix. Then, the premix is sealed and placed at room temperature for plasticization for 6 hours. After taking out, it is extruded and pelletized in a twin-screw extruder at an extrusion temperature of 160 °C to obtain thermoplastic modified polyvinyl alcohol;

[0066] 2) Preparation of seawater degradable material: premix 8 parts of thermoplastic modified...

Embodiment 2

[0068] A seawater degradable material with adjustable use period and degradation period is made from the following raw materials in parts by weight:

[0069] Thermoplastic modified 0388 polyvinyl alcohol: 90 parts;

[0070] Polyhydroxyalkanoate: 10 parts.

[0071] The preparation of the above-mentioned seawater degradable material comprises the following steps:

[0072] 1) Thermoplastic modification of polyvinyl alcohol: Add 0388 polyvinyl alcohol and 1,4-butanediol in a mass ratio of 90:10 to a high-speed mixer for multiple stirrings, stirring for 1 to 2 minutes each time, until fully mixed , the premix was prepared, and then the premix was sealed and placed in a 60°C oven for plasticization for 3 hours. After being taken out, it was extruded and pelletized in a twin-screw extruder at an extrusion temperature of 160°C to obtain a thermoplastic modified polyvinyl alcohol;

[0073] 2) Preparation of seawater degradable material: premix 90 parts of thermoplastic modified poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com