Extraction method of polycyclic aromatic hydrocarbons in ABS, PVC, PP and PS products

An extraction method and polycyclic aromatic hydrocarbon technology, applied in the field of polycyclic aromatic hydrocarbon extraction, can solve a large number of problems, reduce the sensitivity and service life of chromatographic columns and core components of instruments, and long extraction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

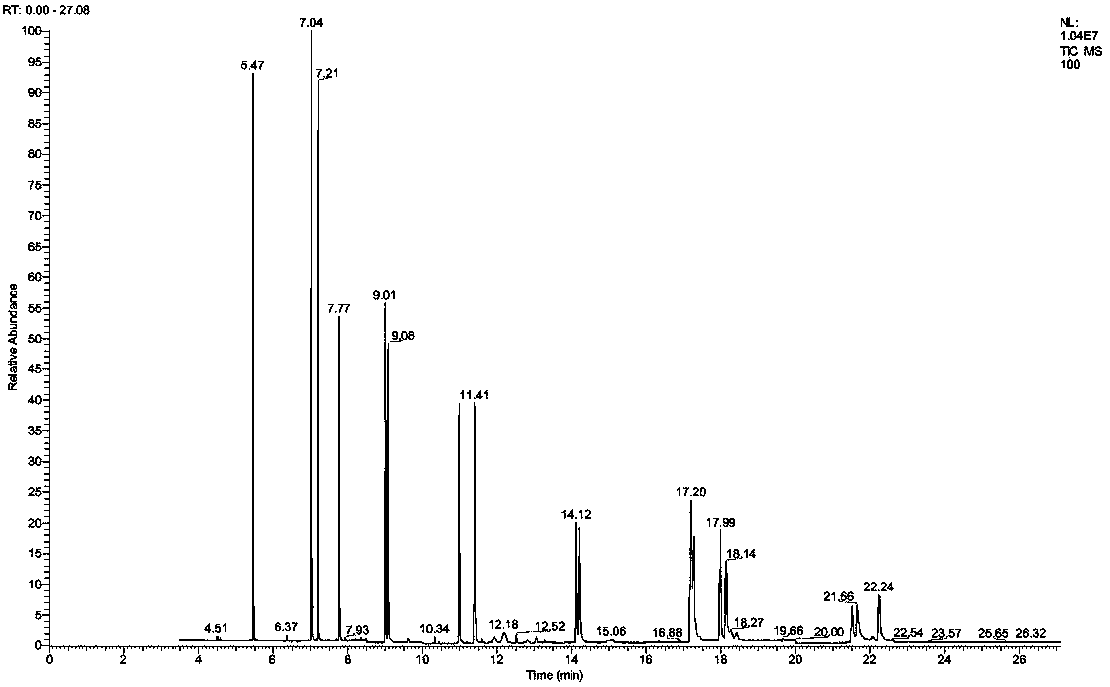

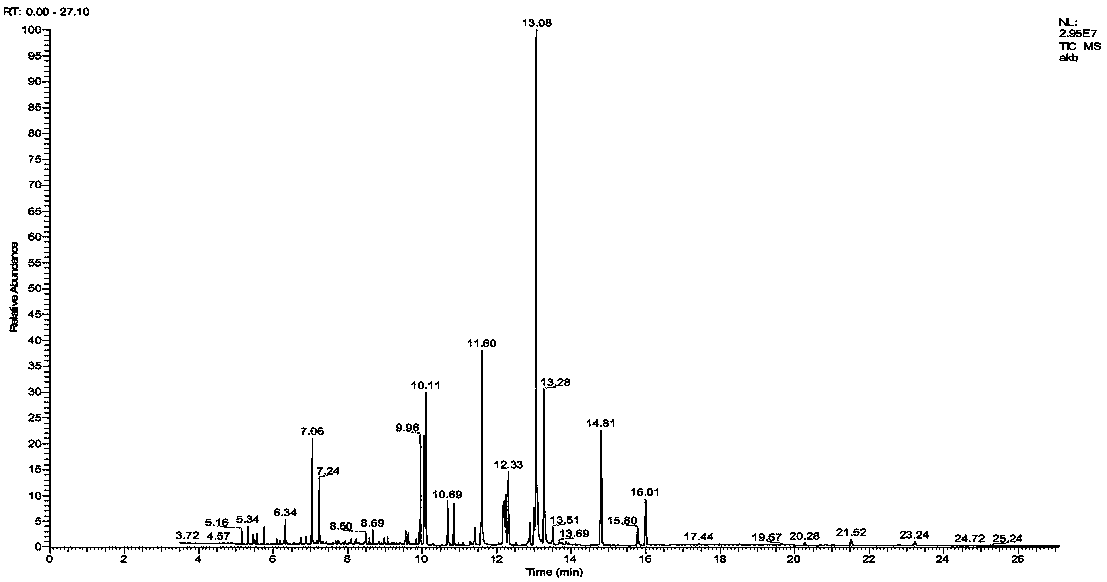

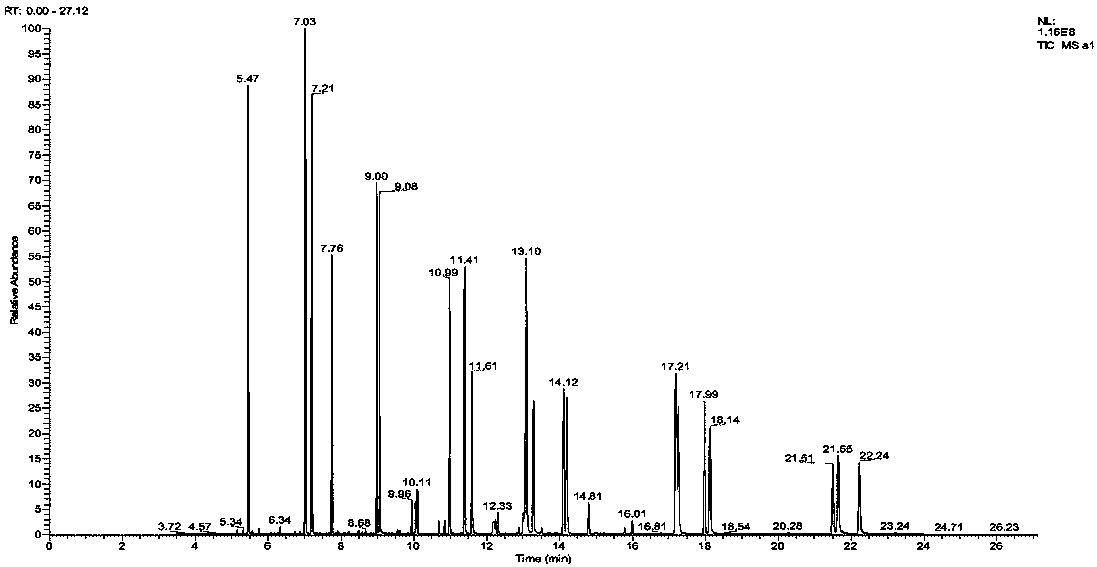

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0048] The invention provides a method for extracting polycyclic aromatic hydrocarbons in ABS, PVC, PP, and PS products. Carry out extraction, and then use an innovative NPME non-polar mixed normal phase extraction method to slowly drop the extract into a non-polar purifying agent with the composition of n-hexane:petroleum ether=90:10, and use the heterogeneous system The instantaneous difference of the thermodynamic force generated by the two immiscible organic phases separates the flocculated substances of the macromolecular polymer, and then uses the normal phase extraction process of the normal phase SPE filler in the non-polar solvent to purify and enrich the target compound, and finally pass After mixing and centrifuging, the supernatant is taken into chromatography to analyze the content of polycyclic aromatic hydrocarbons.

[0049] The technica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com