Manufacturing method of TFT array substrate and TFT array substrate

A technology of an array substrate and a manufacturing method, which is applied in the display field, can solve the problems affecting the carrier mobility of a polysilicon layer, the starting point and direction are disordered and disordered, and there are many grain boundaries between crystal grains, so as to improve the carrier mobility, The effect of low number of grain boundaries and high carrier mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

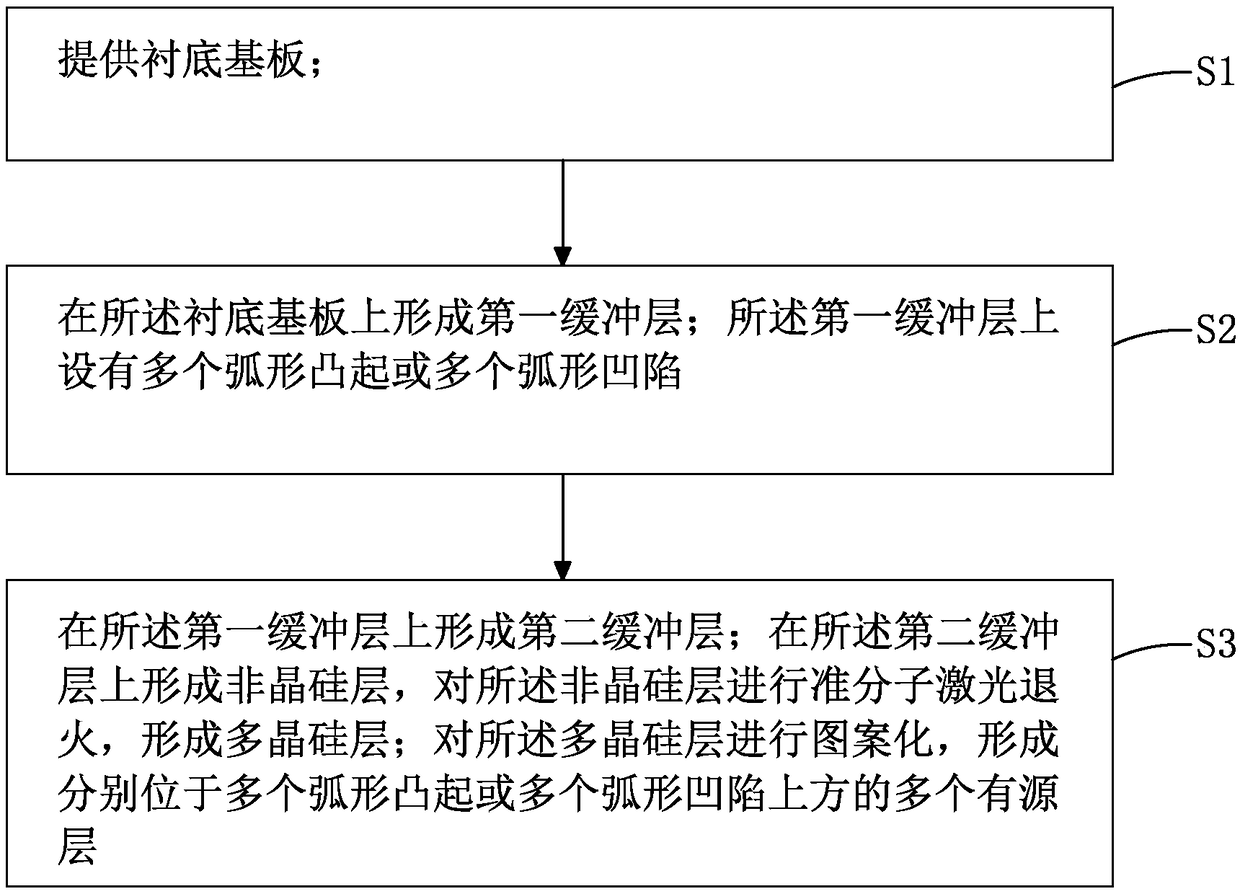

[0044] see figure 1 , and combined with Figure 2 to Figure 11 , the first embodiment of the manufacturing method of the TFT array substrate of the present invention comprises the following steps:

[0045] Step S1, please refer to figure 2 , providing a base substrate 10 .

[0046] Specifically, the material of the base substrate 10 may be glass or a flexible material.

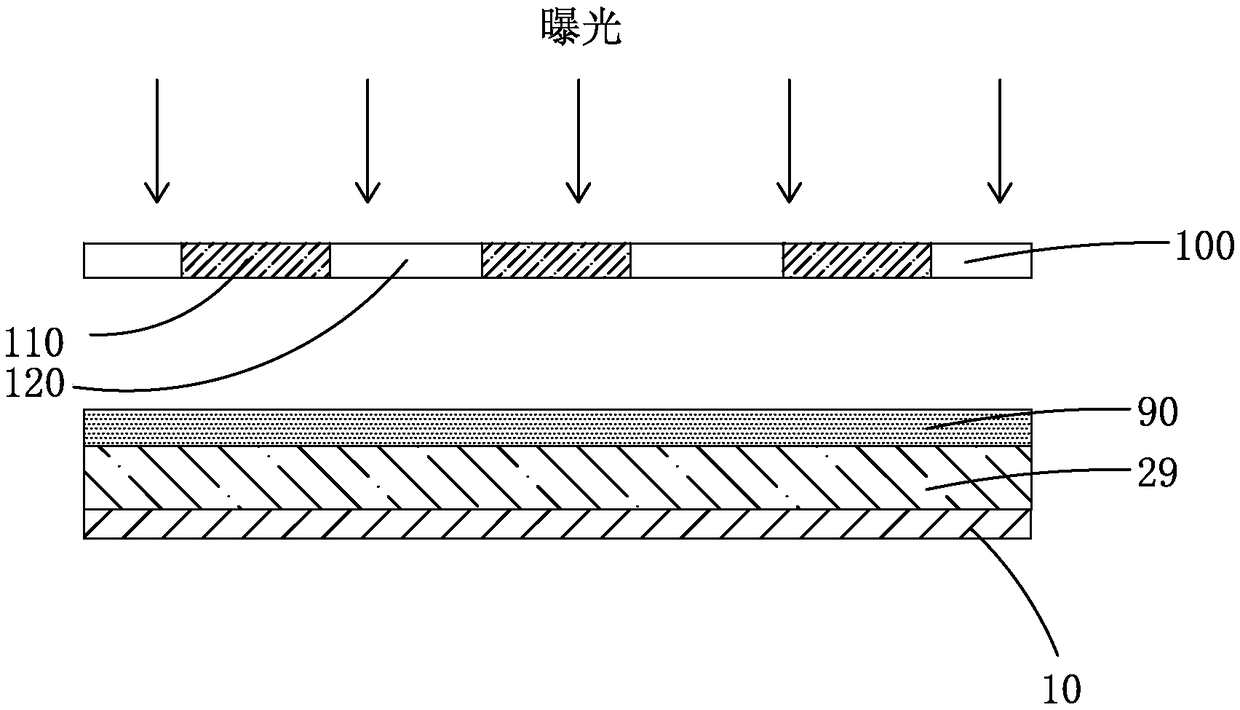

[0047] Step S2, please refer to Figure 6 , forming a first buffer layer 20 on the base substrate 10 . The first buffer layer 20 is provided with a plurality of arc-shaped protrusions 21 .

[0048] Specifically, the material of the first buffer layer 20 is silicon nitride (SiNx), silicon oxide (SiOx) or other materials commonly used in buffer layers in TFT array substrates.

[0049] Specifically, the thickness of the first buffer layer 20 is preferably

[0050] Specifically, in the first embodiment of the present invention, the first buffer layer 20 with a plurality of arc-shaped protrusions 21 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com