Lithium ion battery blending microporous separation membrane preparation method

A technology for lithium-ion batteries and microporous diaphragms, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., and can solve the problem of low electrochemical and safety performance of batteries and uneven pore size distribution of battery diaphragms and other problems, to achieve the effects of reducing polarization, low production cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

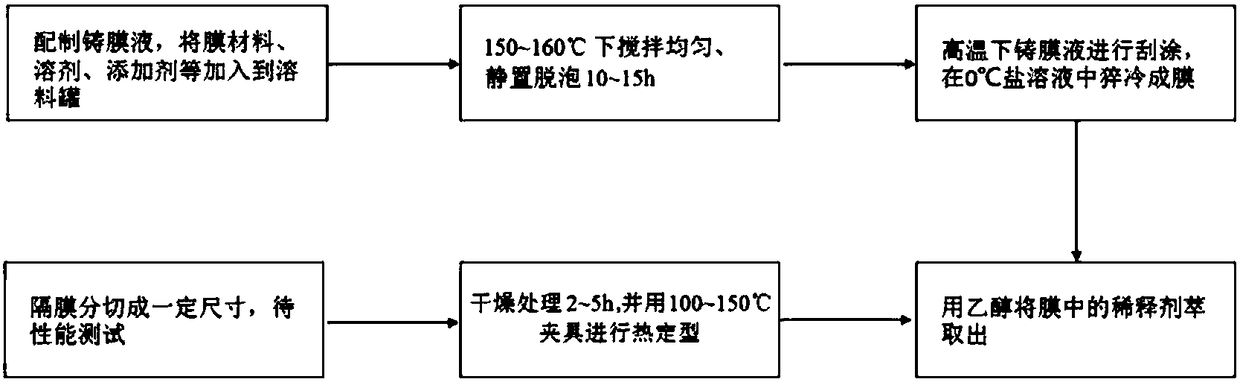

Method used

Image

Examples

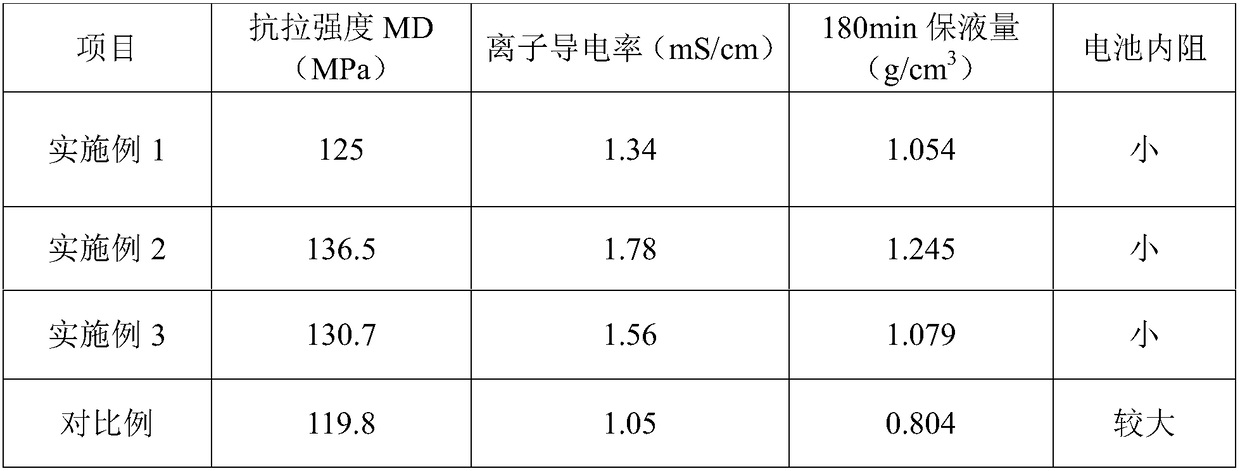

Embodiment 1

[0034] Step 1. Weigh 12% of the membrane material, 4% of glacial acetic acid, 6% of polyvinylpyrrolidone, and 78% of N-methylpyrrolidone according to the mass percentage, and add them to the solvent tank to prepare a mixed solution; wherein, the membrane material The mass ratio of polyvinylidene fluoride to polyethylene is 15:85;

[0035] Step 2. Stir the mixed solution prepared in step 1 under the conditions of 150°C and 300r / min to make it a homogeneous solution, and place it in an electric heating mold at a constant temperature for 12 hours until the membrane material is completely dissolved and there are no bubbles. Prepare casting solution;

[0036] Step 3. Place the cleaned glass plate in an environment of 150°C, and put the casting solution prepared in step 2 close to the glass plate until the casting solution slowly flows to one end of the glass plate, making it lined up , and then use a glass scraper to slowly push the discharged casting solution to the other end of ...

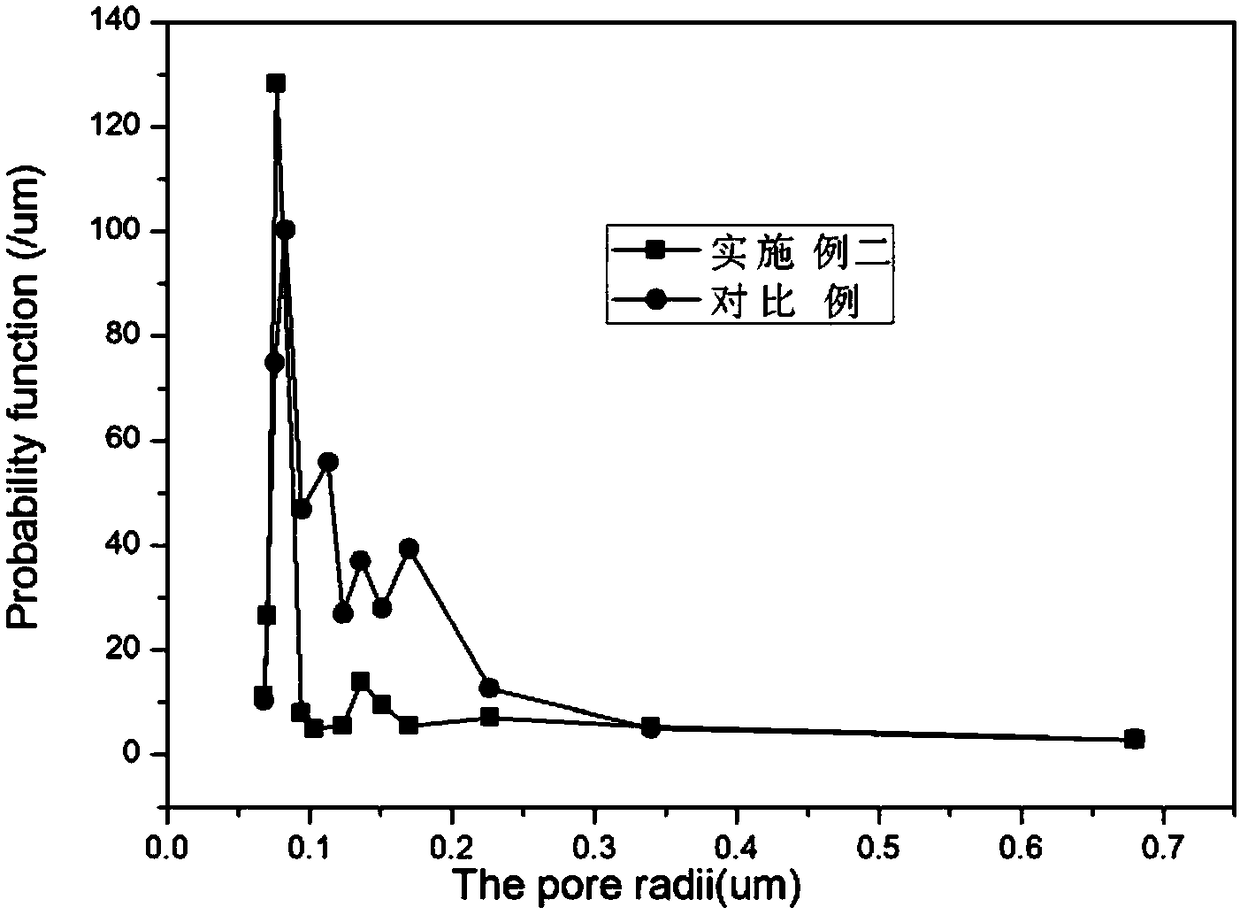

Embodiment 2

[0041]Step 1. Weigh 12% of the membrane material, 4% of glacial acetic acid, 6% of polyvinylpyrrolidone, and 78% of N-methylpyrrolidone according to the mass percentage, and add them to the solvent tank to prepare a mixed solution; wherein, the membrane material The mass ratio of polyvinylidene fluoride to polyethylene is 25:75;

[0042] Step 2. Stir the mixed solution obtained in Step 1 under the conditions of 150°C and 300r / min to make it a homogeneous solution, and place it in an electric heating mold for 12 hours at a constant temperature until the membrane material is completely dissolved and there are no bubbles. to obtain the casting solution;

[0043] Step 3. Place the cleaned glass plate in an environment of 150°C, and place the casting solution prepared in step 2 close to the glass plate until the casting solution slowly flows to one end of the glass plate, making it lined up , and then use a glass scraper to slowly push the discharged casting solution to the other ...

Embodiment 3

[0048] Step 1. Weigh 12% of the membrane material, 4% of glacial acetic acid, 6% of polyvinylpyrrolidone, and 78% of N-methylpyrrolidone according to the mass percentage, and add them to the solvent tank to prepare a mixed solution; wherein, the membrane material The mass ratio of polyvinylidene fluoride to polyethylene is 30:70;

[0049] Step 2. Stir the mixed solution prepared in step 1 under the conditions of 150°C and 300r / min to make it a homogeneous solution, and place it in an electric heating mold at a constant temperature for defoaming for 12 hours until the membrane material is completely dissolved and there are no bubbles , to prepare the casting solution;

[0050] Step 3. Place the cleaned glass plate in an environment of 150°C, and put the casting solution close to the glass plate until the casting solution slowly spreads to one end of the glass plate so that it is lined up, and then use a glass scraper Slowly push the drained casting solution to the other end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com