Adsorbent loaded with alkali active components, preparation method of adsorbent loaded with alkali active components and deep dechlorination method

An alkali activity and adsorbent technology, applied in chemical instruments and methods, refining hydrocarbon oils, alkali metal compounds, etc., can solve the problems of increasing operational risk and complexity, consuming large amounts of hydrogen, and long process routes, and achieving a regeneration process. Simple and effective, excellent dechlorination effect, effect of improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

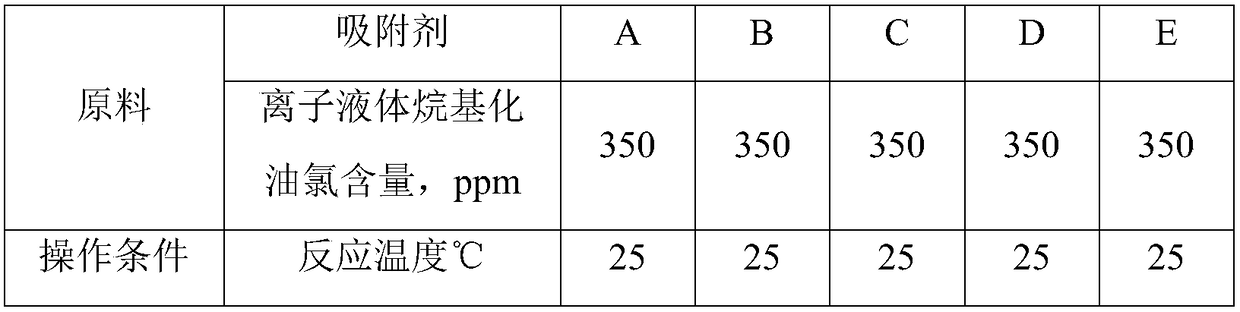

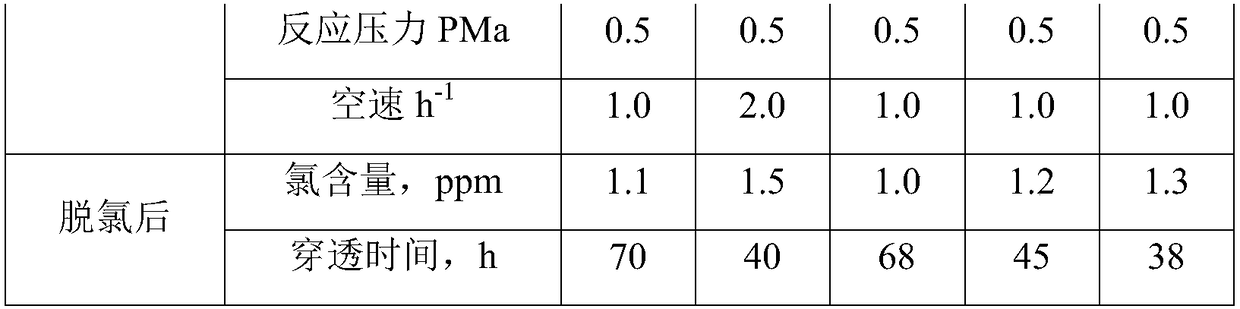

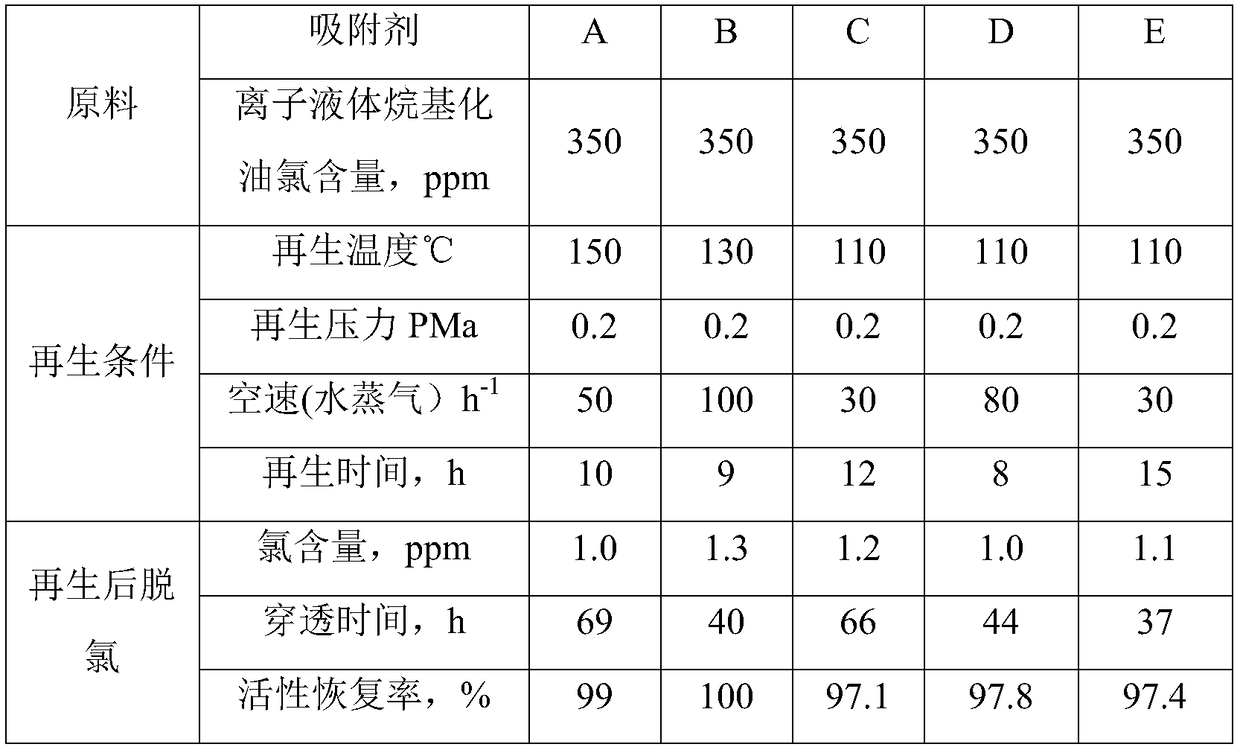

Examples

Embodiment 1

[0036] This embodiment provides a preparation method of an adsorbent loaded with an alkali active component, which comprises the following steps:

[0037] Get aluminum hydroxide (specific surface area 230m 2 / g, pore volume 0.65cm 3 / g) 55.0g, add 45.0g distilled water and 6.5mL concentrated nitric acid, mix well, and make a binder. Take 94.5g of 13X molecular sieve raw powder (silicon-aluminum ratio is 2.1), knead 3.0g of scallop powder and the above-mentioned binder, extrude into a strip, dry the wet strip at 110°C for 12 hours, and roast at 550°C for 4 hours to prepare into an adsorbent carrier.

[0038] Dissolve 29.5g of potassium carbonate in distilled water to make a 110mL solution, add the above-mentioned adsorbent carrier into the impregnation solution, impregnate for 6 hours, then filter, dry at 110°C for 10 hours, and roast at 550°C for 4 hours to make a supported Adsorbent A for alkali-active metal components.

[0039] Include 61.6% 13X molecular sieve, 25.3% al...

Embodiment 2

[0047] This embodiment provides a preparation method of an adsorbent loaded with an alkali active component, which comprises the following steps:

[0048] Get aluminum hydroxide (specific surface area 210m 2 / g, pore volume 0.75cm 3 / g) 55.0g, add 45.0g distilled water and 6.5mL concentrated nitric acid, mix well, and make a binder. Take 94.5g of 13X molecular sieve raw powder (silicon-aluminum ratio is 1.0), knead 2.0g of scallop powder and the above-mentioned binder, extrude into a strip, dry the wet strip at 110°C for 12 hours, and roast at 550°C for 4 hours to prepare into an adsorbent carrier.

[0049] Dissolve 29.5g of potassium carbonate in distilled water to make a 110mL solution, add the above-mentioned adsorbent carrier into the impregnation solution, impregnate for 6 hours, then filter, dry at 110°C for 10 hours, and roast at 550°C for 4 hours to make a supported Adsorbent B for alkaline active components.

[0050] Include 61.9% 13X molecular sieve, 24.9% alumin...

Embodiment 3

[0054] This embodiment provides a preparation method of an adsorbent loaded with an alkali active component, which comprises the following steps:

[0055] Get aluminum hydroxide (specific surface area 230m 2 / g, pore volume 0.65cm 3 / g) 55.0g, add 45.0g distilled water and 6.5mL concentrated nitric acid, mix well, and make a binder. Take 94.5g of 13X molecular sieve raw powder (silicon-aluminum ratio is 5), knead 3.0g of scallop powder and the above-mentioned binder, extrude into strips, dry the wet strips at 110°C for 12 hours, and roast at 550°C for 4 hours to prepare into an adsorbent carrier.

[0056] Dissolve 29.5g of potassium carbonate in distilled water to make a 110mL solution, add the above-mentioned adsorbent carrier into the impregnation solution, impregnate for 6 hours, then filter, dry at 110°C for 10 hours, and roast at 550°C for 4 hours to make a supported Adsorbent C for alkaline active components.

[0057] Include 61.5% 13X molecular sieve, 25.3% aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com