A kind of preparation method of two-dimensional nanosheet

A two-dimensional nanometer, manganese acetate technology, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve the problems of low specific capacitance of nickel hydroxide and poor cycle stability, and achieve mild preparation conditions, simple process and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 4mmoL nickel acetate and 0.5mmoL manganese acetate into 20mL deionized water, stir evenly, then add 1mL ammonia water while stirring; use magnetic stirring for 0.5h to obtain precipitation;

[0033] (2) Pour the precipitate into a polytetrafluoroethylene-lined stainless steel autoclave, heat up to 120°C, react for 6 hours, and cool after the reaction;

[0034] (3) The reaction product was centrifuged to obtain a solid powder, which was then washed with distilled water and ethanol in turn, and then dried at 60°C for 24 hours to obtain Mn 0.11 Ni 0.89 (OH) 2 Two-dimensional nanosheets.

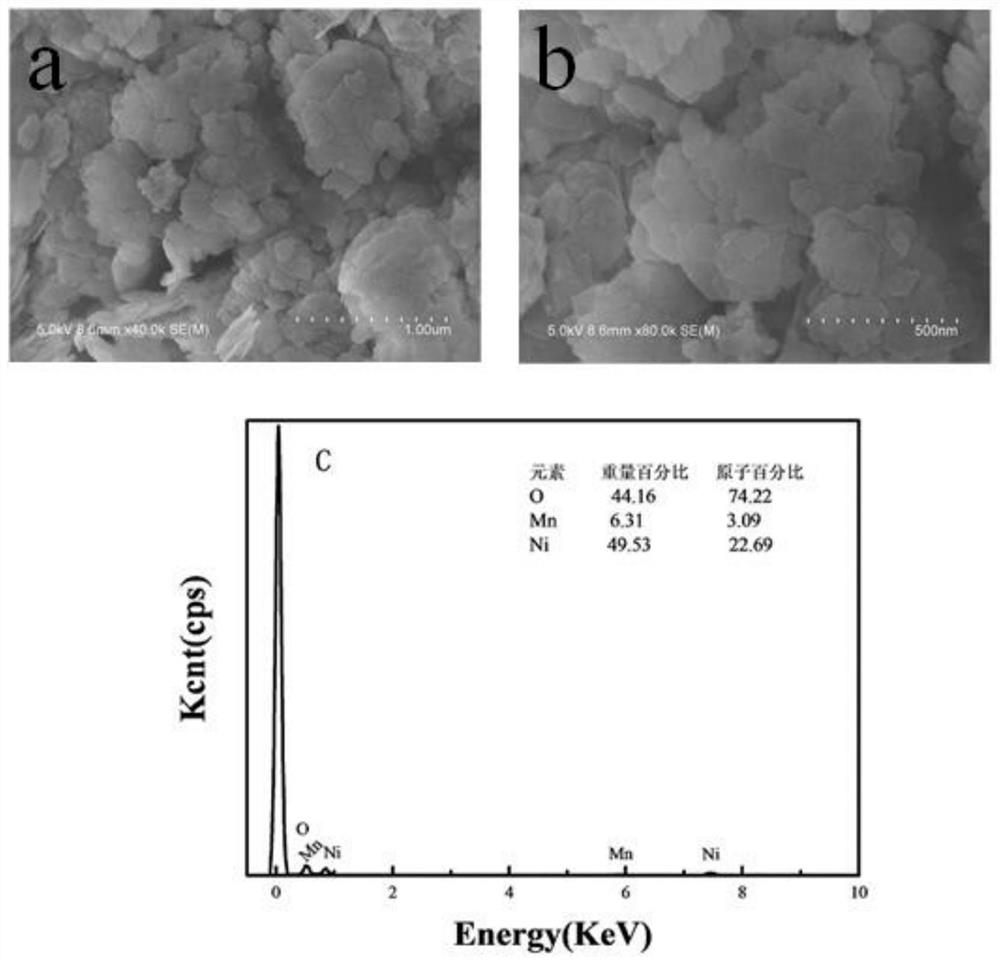

[0035] The prepared Mn 0.11 Ni 0.89 (OH) 2 Two-dimensional nanosheet products were analyzed.

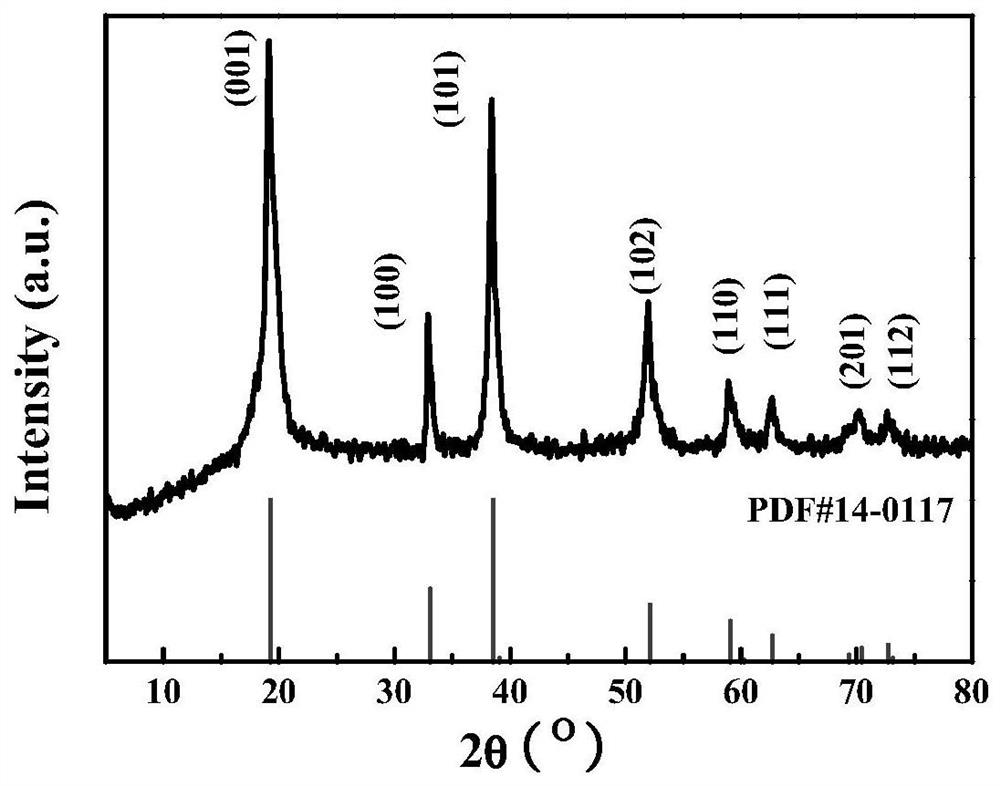

[0036] Such as figure 1 Shown, is the XRD pattern of embodiment 1 product, can find out from the figure that all diffraction peaks are all consistent with standard layered α-Ni(OH) 2 (Card No.: PDF#14-0117) corresponding to the crystal spectrum. The peaks at the diffraction angl...

Embodiment 2

[0039] (1) Add 4mmoL nickel acetate and 1mmoL manganese acetate into 20mL deionized water, stir evenly, then add 1mL ammonia water while stirring; use magnetic stirring for 0.5h to obtain precipitation;

[0040] (2) Pour the precipitate into a polytetrafluoroethylene-lined stainless steel autoclave, heat up to 120°C, react for 6 hours, and cool after the reaction;

[0041] (3) The reaction product was centrifuged to obtain a solid powder, which was then washed with distilled water and ethanol in turn, and then dried at 60°C for 24 hours to obtain Mn 0.2 Ni 0.8 (OH) 2 Two-dimensional nanosheets.

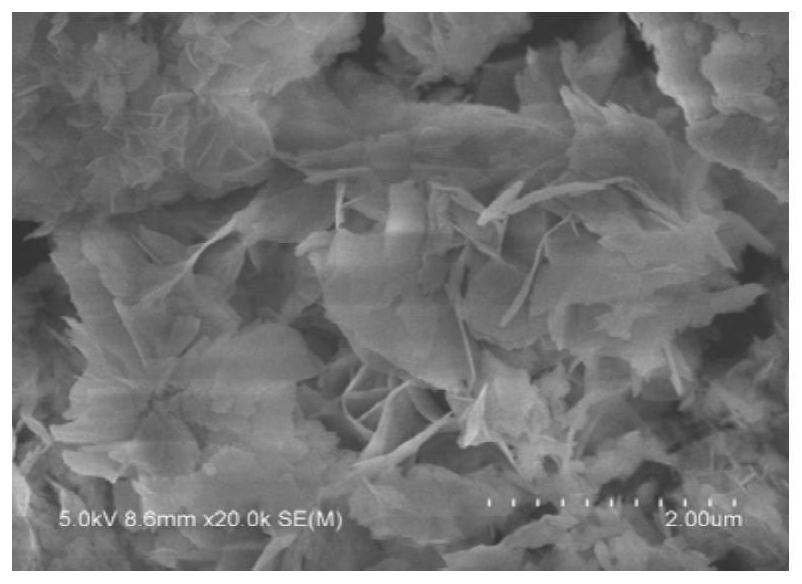

[0042] The product that this embodiment makes is basically consistent with embodiment 1, and its scanning electron microscope picture is as image 3 shown.

Embodiment 3

[0044] (1) Add 4mmoL nickel acetate and 2mmoL manganese acetate into 20mL deionized water, stir evenly, then add 1mL ammonia water while stirring; use magnetic stirring for 0.5h to obtain precipitation;

[0045] (2) Pour the precipitate into a polytetrafluoroethylene-lined stainless steel autoclave, heat up to 120°C, react for 6 hours, and cool after the reaction;

[0046] (3) The reaction product was centrifuged to obtain a solid powder, which was then washed with distilled water and ethanol in turn, and then dried at 60°C for 24 hours to obtain Mn 0.67 Ni 0.33 (OH) 2 Two-dimensional nanosheets.

[0047] The product that this embodiment makes is basically consistent with embodiment 1, and its scanning electron microscope picture is as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com